Guide line sealing structure and lamp using same

A technology of wire sealing and wire, which is applied to the components of lighting devices, lighting devices, circuit layout, etc., can solve problems such as lamp sealing failure, and achieve the effects of reliable sealing, increased compression, and improved sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

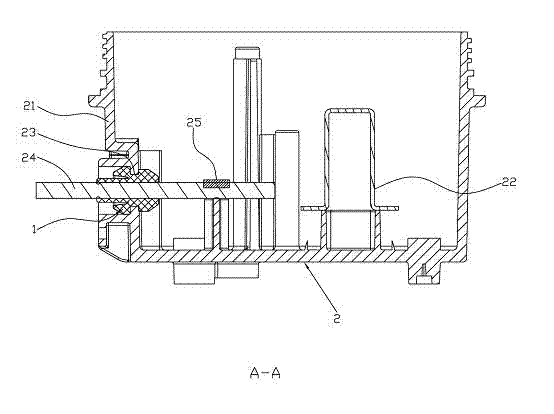

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

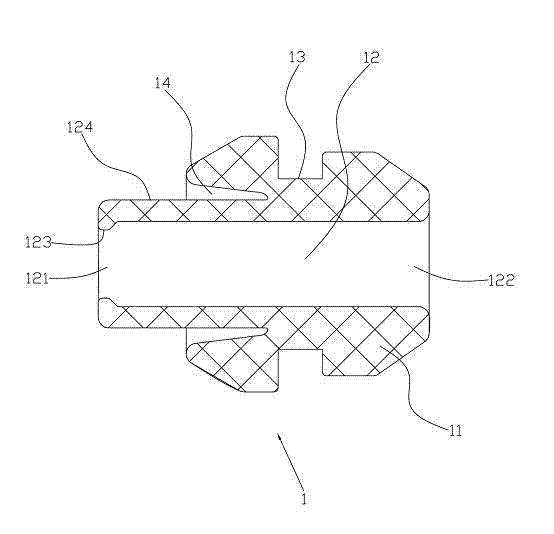

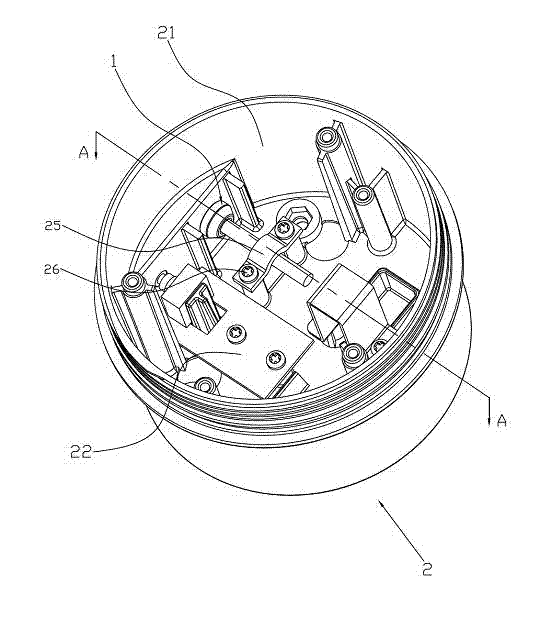

[0019] like figure 1 As shown, a wire sealing structure 1 provided by the embodiment of the present invention is used to seal wires ( figure 1 not shown) with the cable entry hole ( figure 1 not shown), the wire sealing structure 1 includes a base body 11, the base body 11 is arranged in the wire inlet hole and closely fits with the wire inlet hole, so that the sealing connection between the base body 11 and the wire inlet hole is made; on the base body 11 There is a wire fixing hole 12 coaxial with the wire inlet hole, and the wire is passed through the wire fixing hole 12 and tightly matched with the wire fixing hole 12, so that the wire fixing hole 12 and the wire are sealed and connected.

[0020] Wherein, the connection method of the base body 11 provided in the wire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com