Engine cylinder head sealing gasket

A technology for engine cylinders and gaskets, which is applied to engine sealing devices, engine components, machines/engines, etc., and can solve problems such as small force, reduced service life, and difficulty in ensuring position and height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the present invention is described in detail in conjunction with accompanying drawing and specific embodiment:

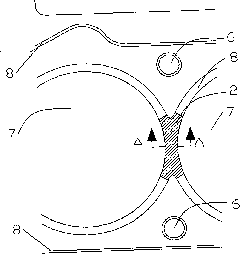

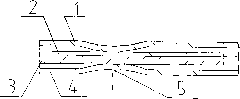

[0015] see figure 1 and figure 2 The engine cylinder head gasket of the present invention is composed of an upper elastic plate 1, a base plate 3 and a lower elastic plate 4, and the upper and lower elastic plates 1 and 4 are provided with grooves 5 along the edges of the cylinder bore, and the two concave The grooves 5 are symmetrical to each other, have the same size, and have a semicircular longitudinal section. A gasket 2 is provided between the upper elastic plate and the base plate. At the position between the cylinder holes 7 on the gasket, a gasket 2 is provided between the upper elastic plate and the base plate, and is integrally connected with the base plate 3 . Both sides of the gasket 2 and the outer sides of the upper elastic plate 1 and the lower elastic plate 4 are coated with a micro-sealing material.

[0016] Spacer 2 is a metal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com