Intelligent adaptive cutting vibration suppression method and system of tool room machine

A vibration suppression and adaptive technology, which is applied in the field of machine tool intelligent adaptive cutting vibration suppression and system, can solve the problems of high-end machine tools, such as high price and difficult popularization, and avoid signal delay phenomenon, solve High price, effect of improving cutting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

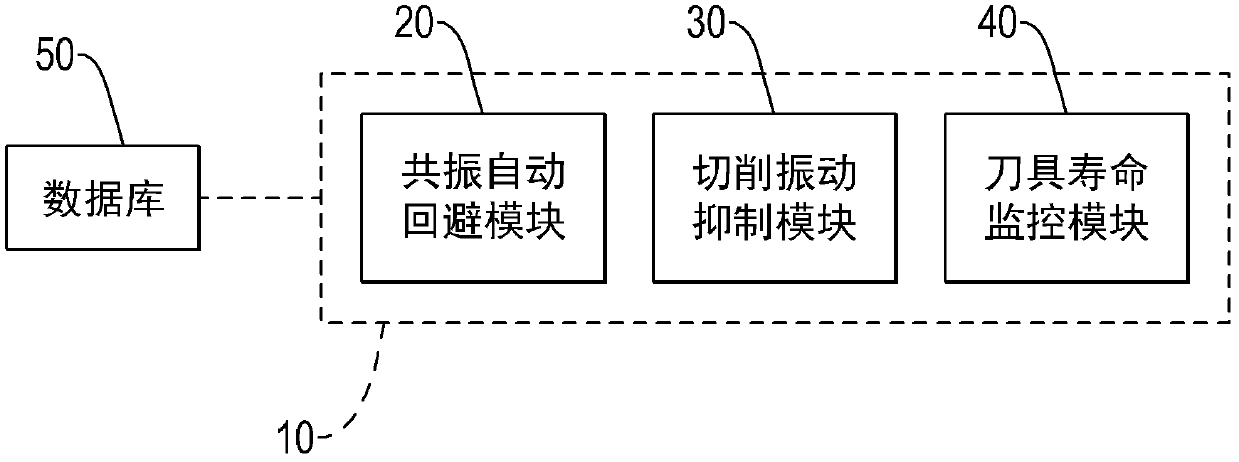

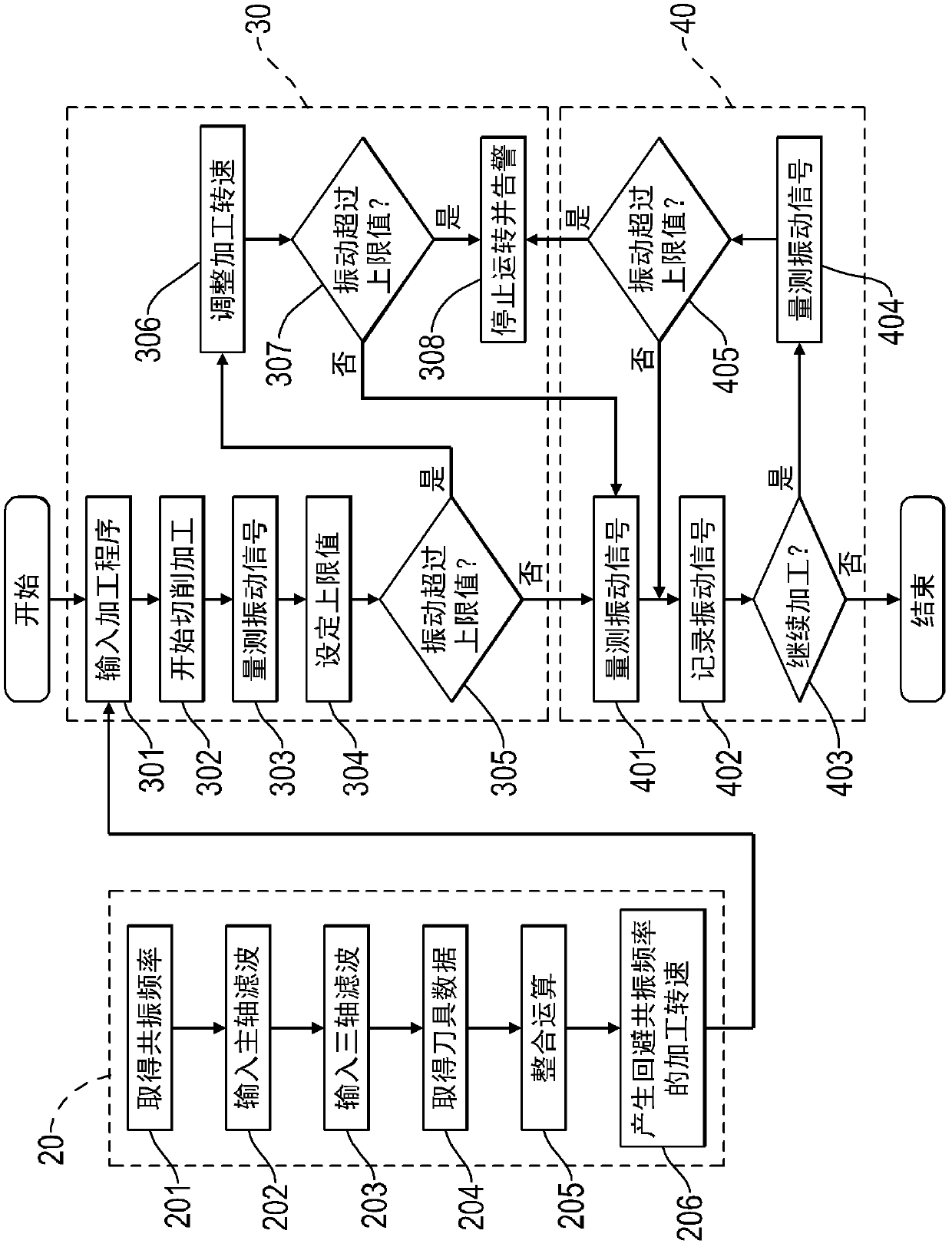

[0027] figure 1 As a preferred embodiment of the present invention, a controller 10 includes a resonance automatic avoidance module 20, a cutting vibration suppression module 30 and a tool life monitoring module 40, wherein the controller 10 is further connected with a database 50, The database 50 can be built in the controller 10 or set outside the controller 10 .

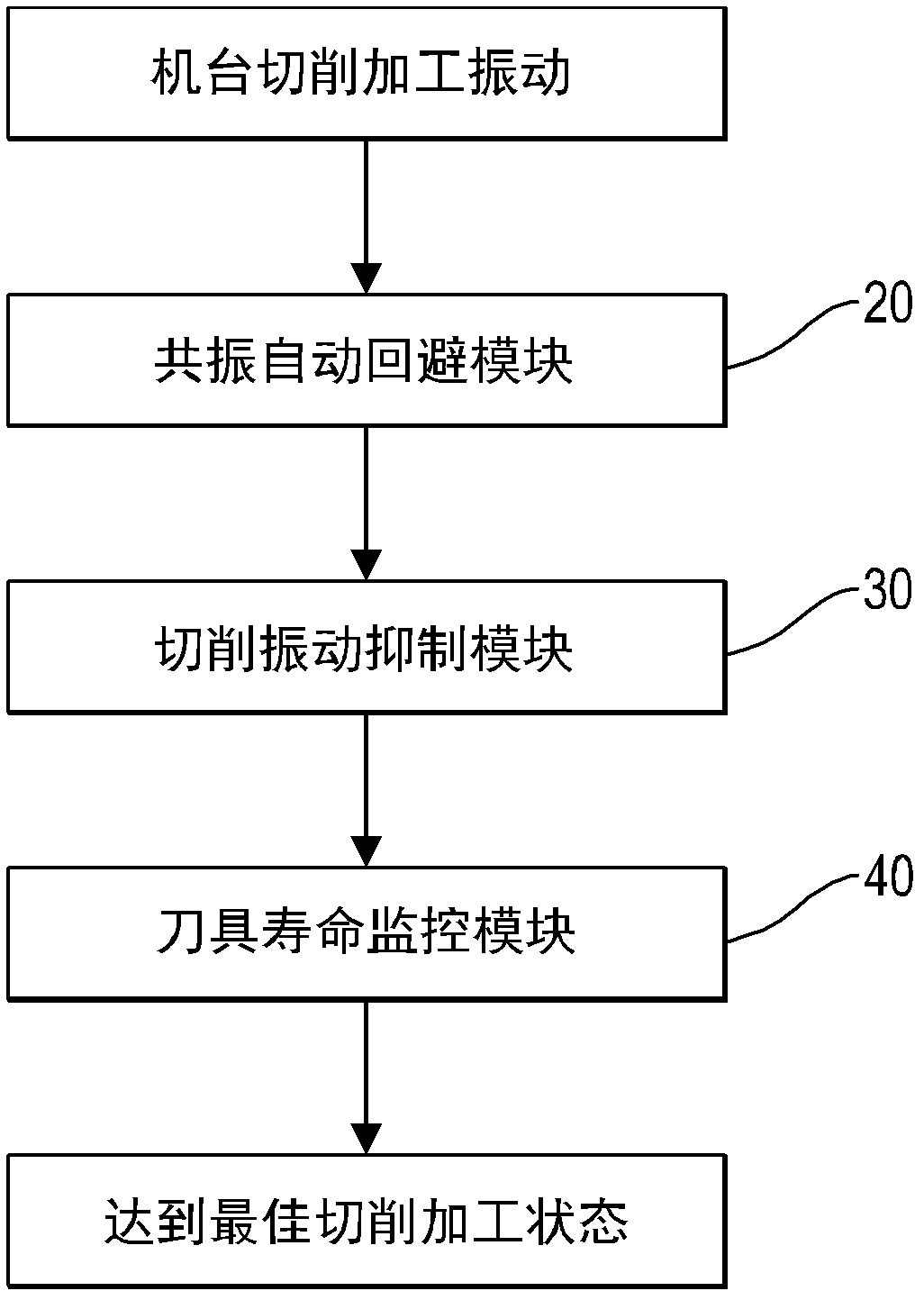

[0028] See figure 2 As shown, in order to keep the machine tool in the best cutting state, the following programs are executed in the controller 10 in sequence by the resonance automatic avoidance module 20, the cutting vibration suppression module 30 and the tool life monitoring module 40 respectively:

[0029] The resonance automatic avoidance module 20 obtains the pre-stored resonance frequency of each component of the machine from the database 50, and performs calculations in combination with the resonance frequency of the selected tool to avoid the machining speed that causes the machine to resonate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com