Fast manager for glue injection in vacuum infusion of fiber reinforced plastics

A technology of vacuum introduction and glass fiber reinforced plastics, which is applied in the field of glass fiber reinforced plastics vacuum introduction glue injection fast manager, which can solve the problems that the control of resin amount and resin introduction speed cannot be satisfactorily solved, the curing cycle and product quality are affected, and resin waste is achieved. Glue feeding control is flexible and convenient, practical and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

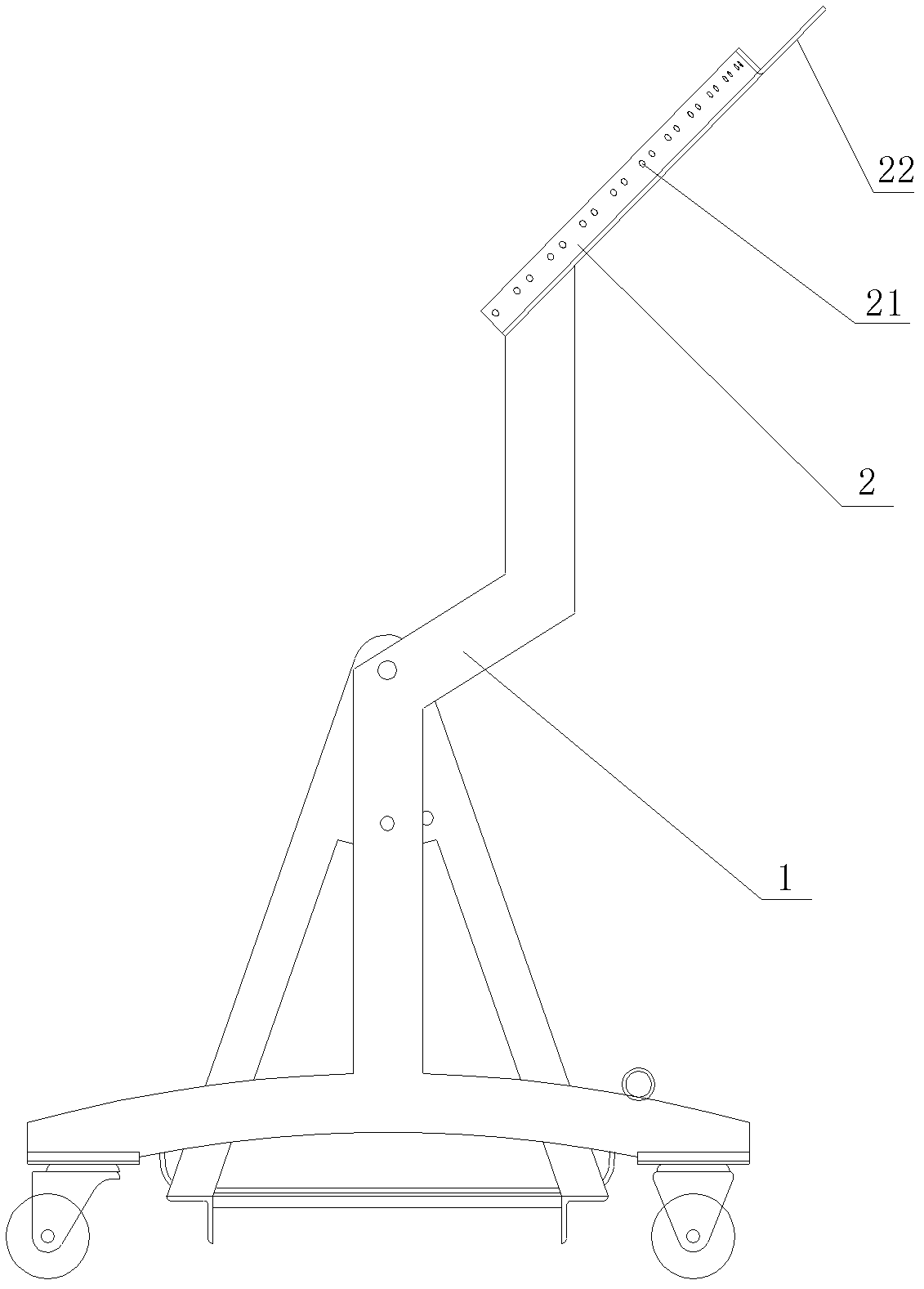

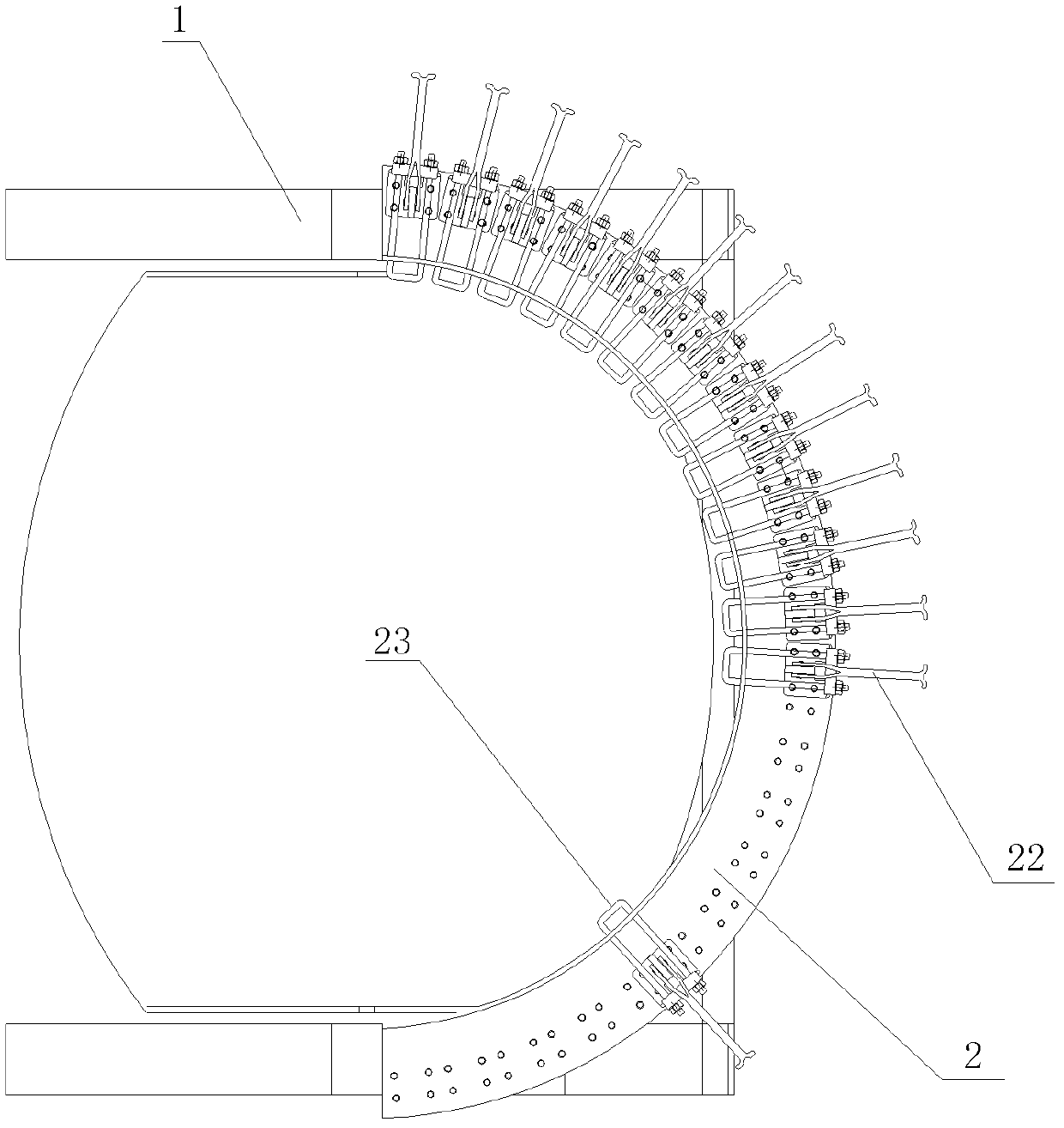

[0013] See figure 1 , figure 2 , the present invention has main frame 1, and main frame 1 is provided with semicircular sub-frame 2, and sub-frame 2 is provided with twenty controllers 22 and twenty control rings 23; 23 passes through the corresponding sliding holes 21 on the sub-frame 2 and is fixedly connected with corresponding controllers 22 . The rubber inlet pipes pass through the control ring 23 and are arranged in an orderly manner on the sub-frame 2, making the operation more clear and flexible. By rotating the controller 22, the control ring 23 moves up and down in the sliding hole 21, thereby changing the inner diameter of the control ring 23, so that the amount and speed of glue feeding can be controlled more quickly.

[0014] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com