Clutch drive type double-layer adjustable plug

A driving type and plugging technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of prolonging the measurement and adjustment cycle, low testing efficiency, low fishing efficiency, etc., and achieves the simplification of the measurement and adjustment process , the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

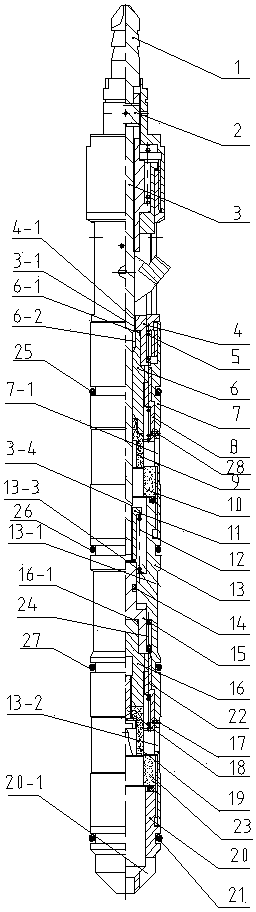

[0014] The present invention is provided with fishing head 1, the drive shaft 3 that is connected with fishing head 1, the lower end of fishing head 1 outside drive shaft 3 is connected with upper casing 7, the lower end of upper casing 7 is connected with lower casing 13, and the lower end of lower casing 13 is connected with Lower joint 20.

[0015] An upper drive sleeve 4 is set between the upper shell 7 at the lower end of the fishing head 1 and the drive shaft 3 , and a spring 5 parallel to the axial direction is set between the upper drive sleeve 4 and the lower end of the fishing head 1 .

[0016] Cooperate with the spline sleeve 4-1 on the inner surface of the upper end of the upper drive sleeve 4 through the spline 3-1 on the outer side of the middle part of the drive shaft 3, and connect the upper silk shaft 6 through the transmission key in the middle part of the upper drive sleeve 4, and the upper silk shaft 6 is sleeved Outside the drive shaft 3, an upper wire sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com