Transmission wheel arrangement

A transmission gear and wheel hub technology, which is applied to transmission parts, hoisting devices, portable lifting devices, etc., can solve the problem of shortening the structural length of transmission gears, and achieve the effect of improving radial support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

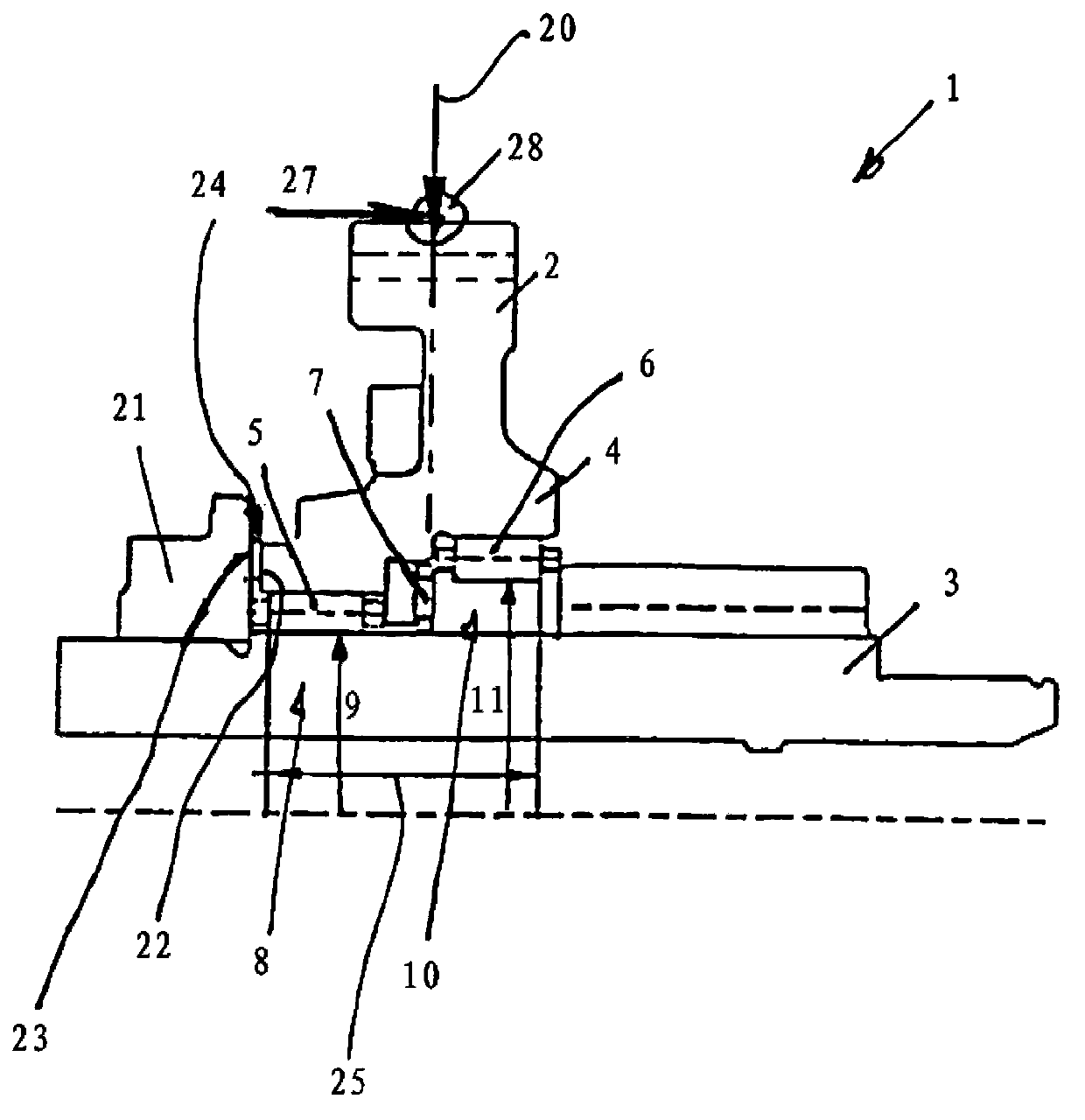

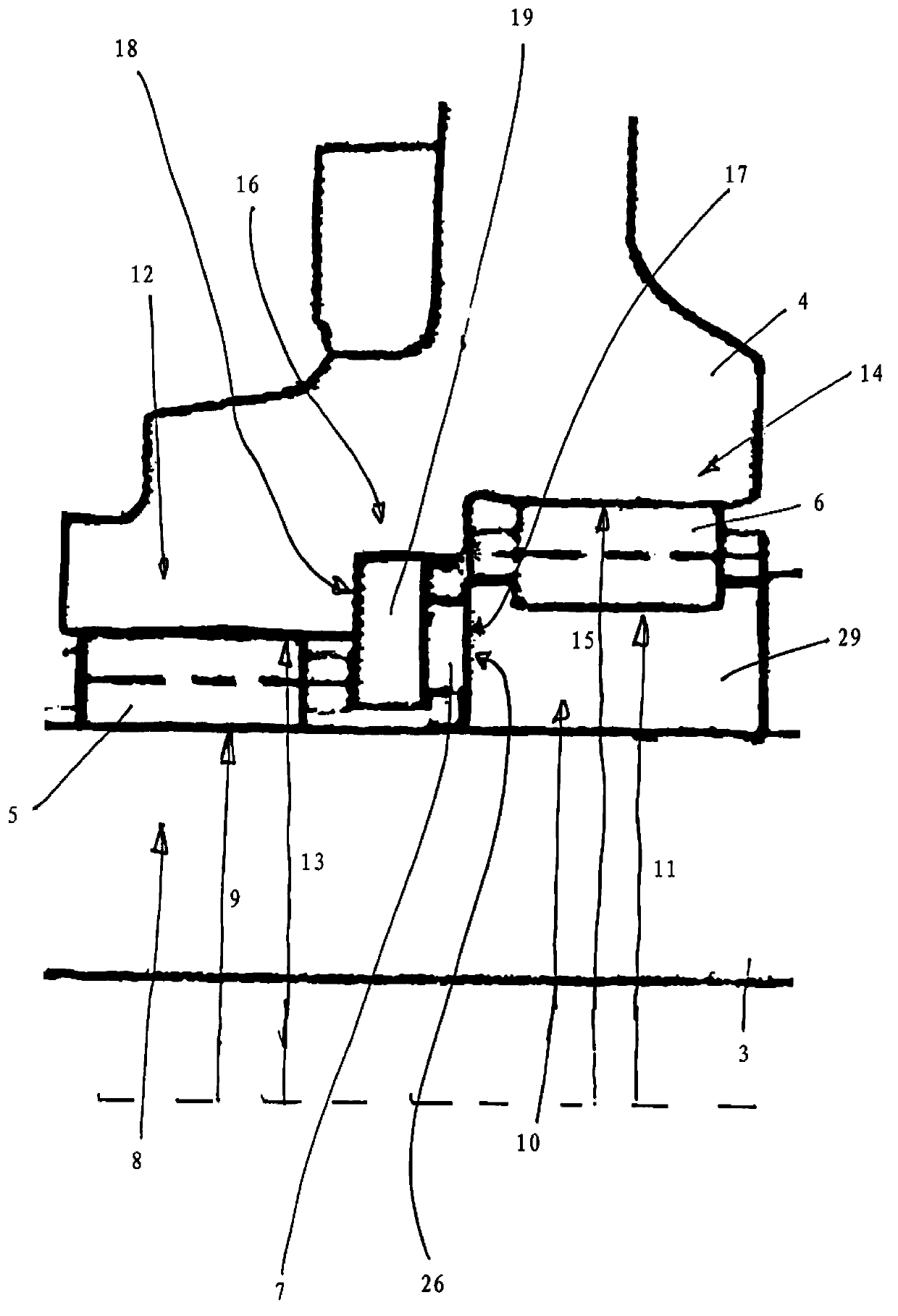

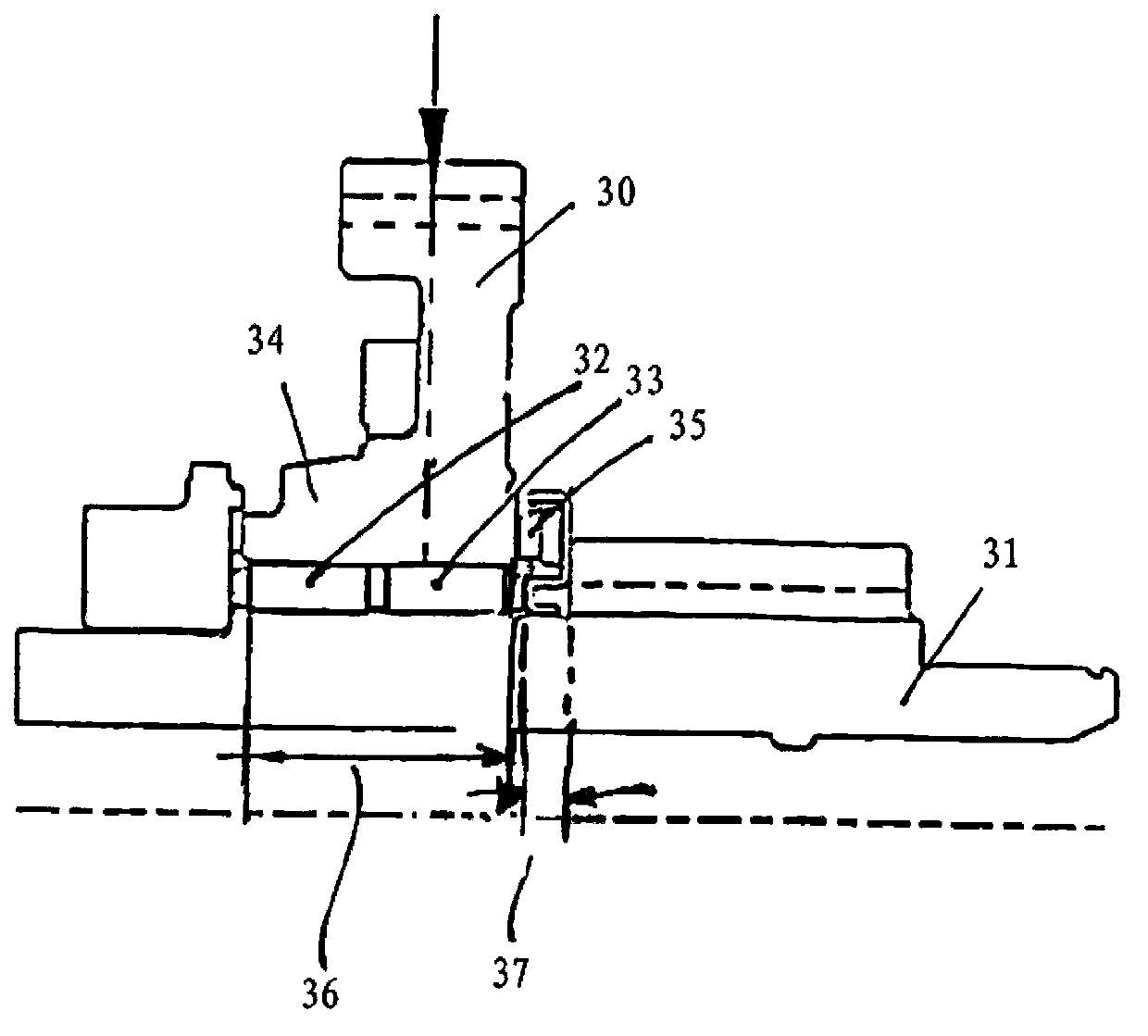

[0022] figure 1 A half-side partial sectional view of the transmission gear unit 1 with the transmission gear 2 and the shaft 3 is shown. In this case, a part of the transmission gear, which can also be referred to as a shift gear, is arranged rotatably on the shaft 3 . The transfer gear 2 has a radially outer region with gear teeth and a radially inner region also referred to as hub 4 . Preferably two radial bearings 5 , 6 and an axial bearing 7 are arranged between the hub 4 of the drive gear 2 and the shaft 3 . here figure 1 It can be seen that the two radial bearings 5 , 6 and the axial bearing 7 are arranged radially between the hub 4 of the drive gear 2 and the shaft 3 . In another embodiment, as a variant, more than two radial bearings can also be arranged.

[0023] exist figure 1 and figure 2 In the illustrated embodiment, the axial bearing 7 is arranged axially between the two radial bearings 5 and 6 .

[0024] exist figure 1 and figure 2 It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com