Oil chromatographic analysis standard sample injector

A technology for analyzing standards and sample injectors, applied in the direction of analyzing materials, instruments, scientific instruments, etc., to achieve the effect of precise air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

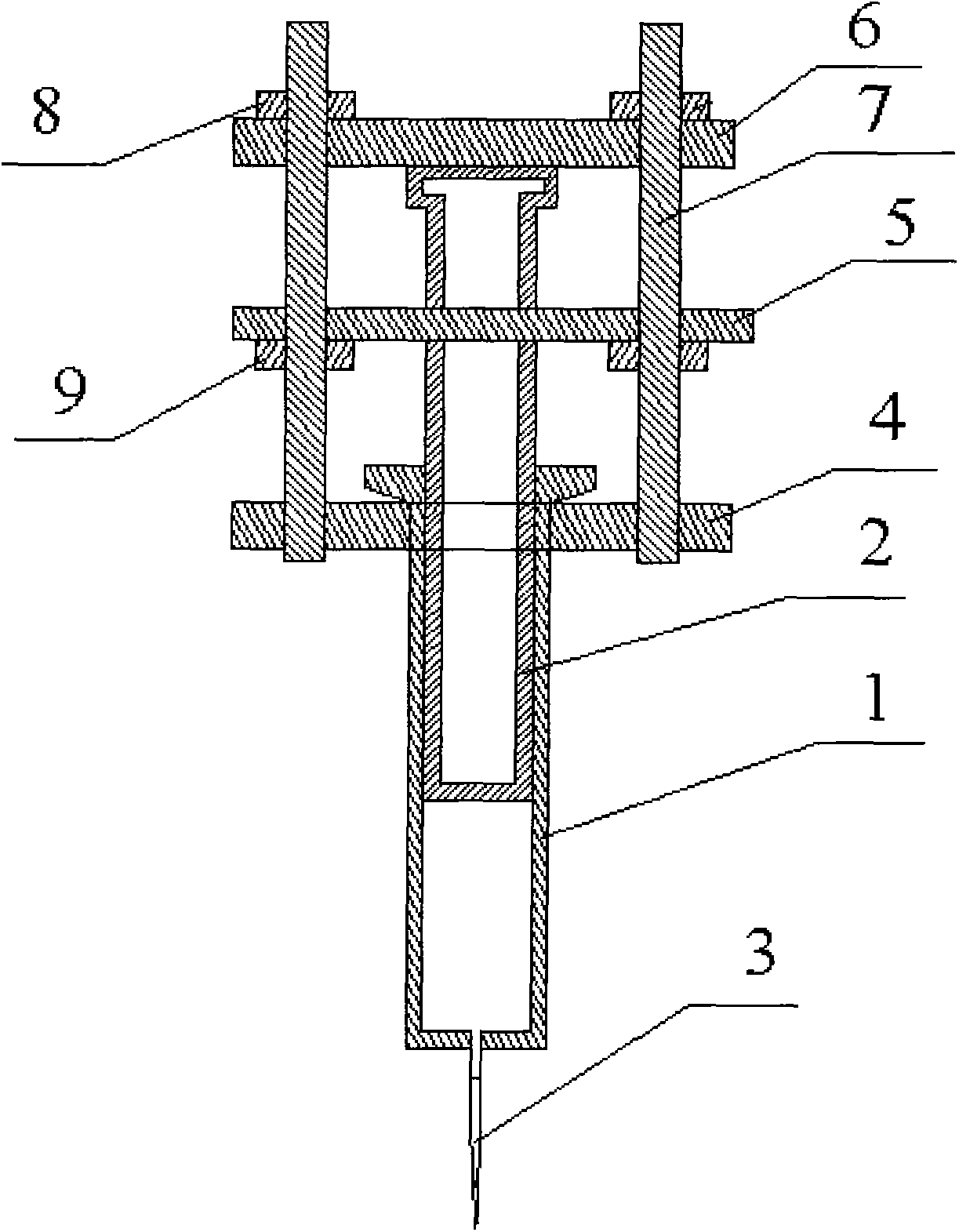

[0015] Attached below Figure 1-3 The present invention will be described in detail.

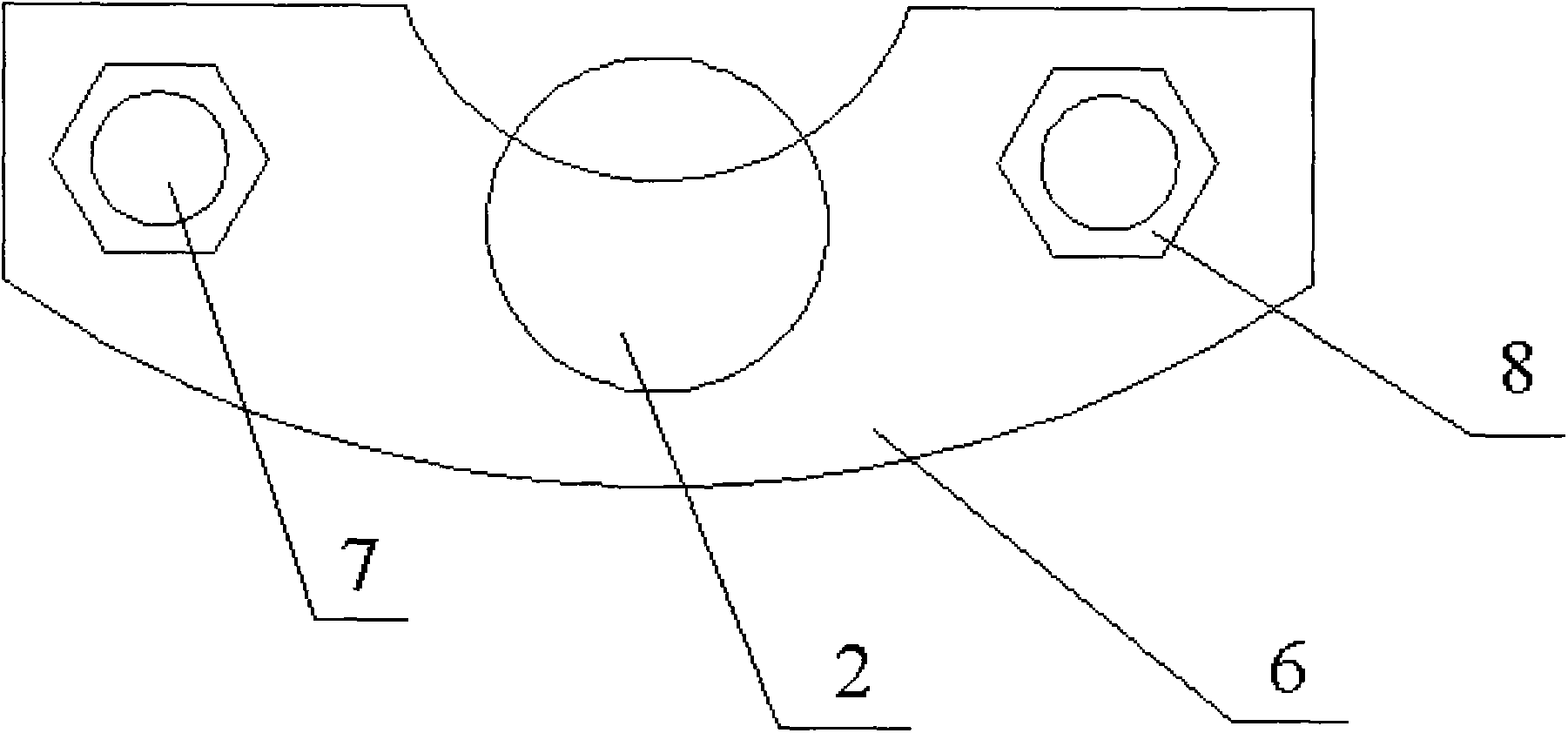

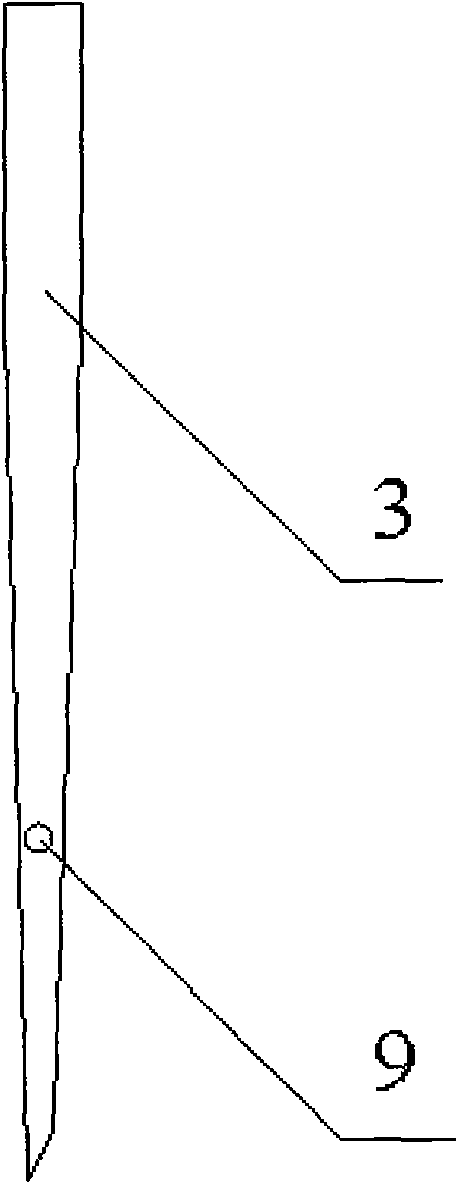

[0016] refer to figure 1 , the oil chromatographic analysis standard sampler of the present invention is made up of syringe barrel 1, syringe push rod 2, syringe needle 3 and fixed support, wherein fixed support includes fixed plate 4, control plate 5, upper baffle plate 6 and connects above-mentioned three The screw of the plate and the fixing nut, the fixing plate is fixed on the syringe barrel 1, and the top of the syringe push rod 2 is provided with an upper baffle 6. Since the injection port of the chromatograph has a certain pressure, the upper baffle 6 ensures that the syringe push rod 2 will not be ejected under the action of the pressure gas, avoiding the risk of operation failure, the upper baffle 6 and the fixed plate 4 are connected by two screw rods 7, and the upper baffle nut is set on the upper part of the upper baffle 6 for fixing.

[0017] In addition, a control board 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com