Disk-type movable safety socket

A safety socket, disc-type technology, applied in the field of disc-type movable safety sockets, can solve problems such as low safety factor, short circuit, and no socket setting, etc., achieve strong heat dissipation function, avoid damage, and reduce temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

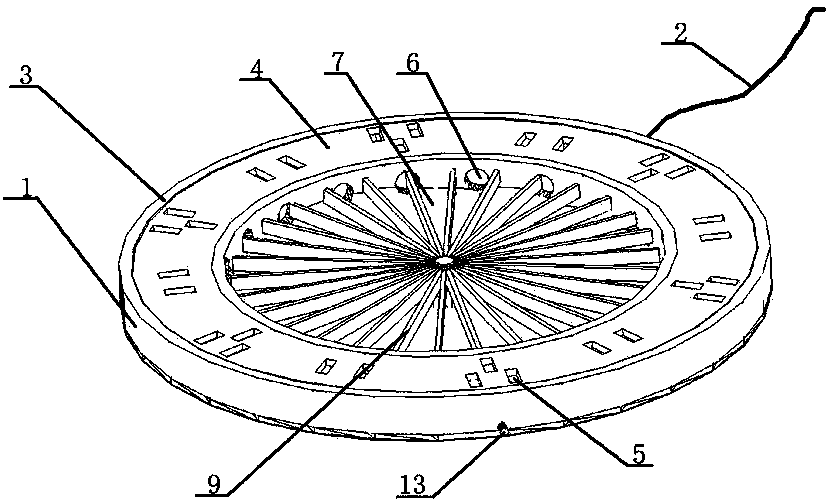

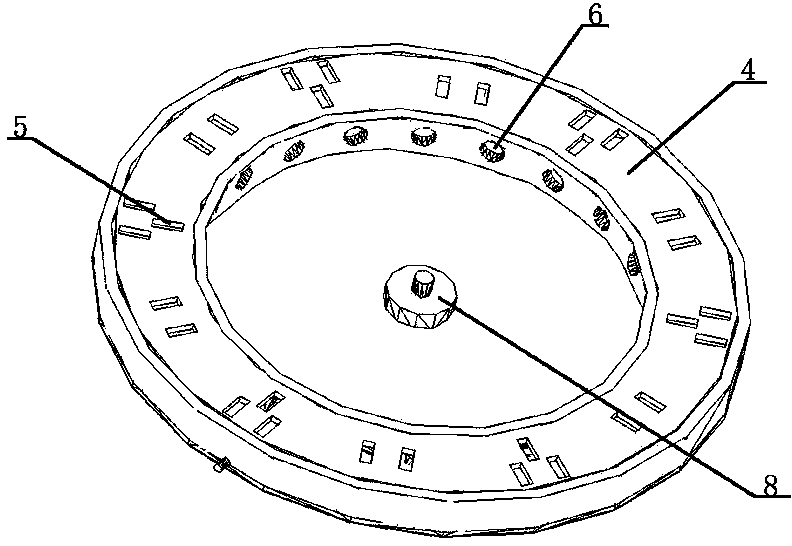

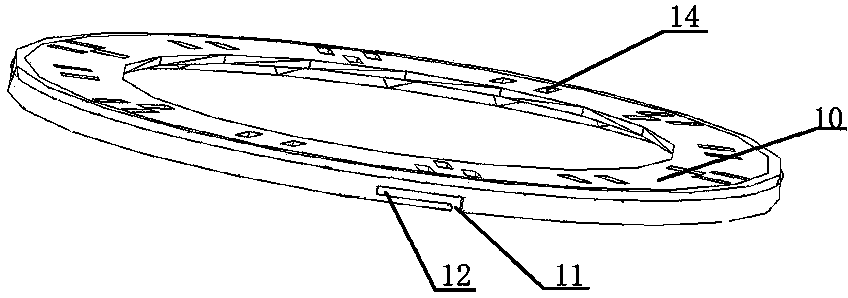

[0016] As shown in the figure: a disc-type movable safety socket includes a socket housing 1 and an external power plug 2 , and the jack circuit is arranged in the socket housing 1 . The socket housing 1 is an annular housing, and the annular outer edge of the socket housing 1 is provided with an annular working indicator light 3. The socket housing 1 has an annular socket panel 4, and 12 socket panels are arranged on the socket panel 4. Panel jacks 5, the distances between two adjacent panel jacks 5 are the same; a plurality of ventilation holes 6 are evenly opened on the annular inner wall of the socket housing 1, and the upper and lower surfaces of the inner circle of the socket housing 1 are provided with There is a protective cover plate 7; a micro motor 8 is arranged between the upper and lower protective cover plates 7, and the output shaft of the micro motor 8 is connected to the fan blade 9; the socket also includes a protective cover 10, which can be snapped together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com