Microfluidic chip for producing multicomponent droplets

A microfluidic chip and microdroplet technology, applied in the field of microfluidics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment A kind of microfluidic chip for producing concentration gradient microdroplets

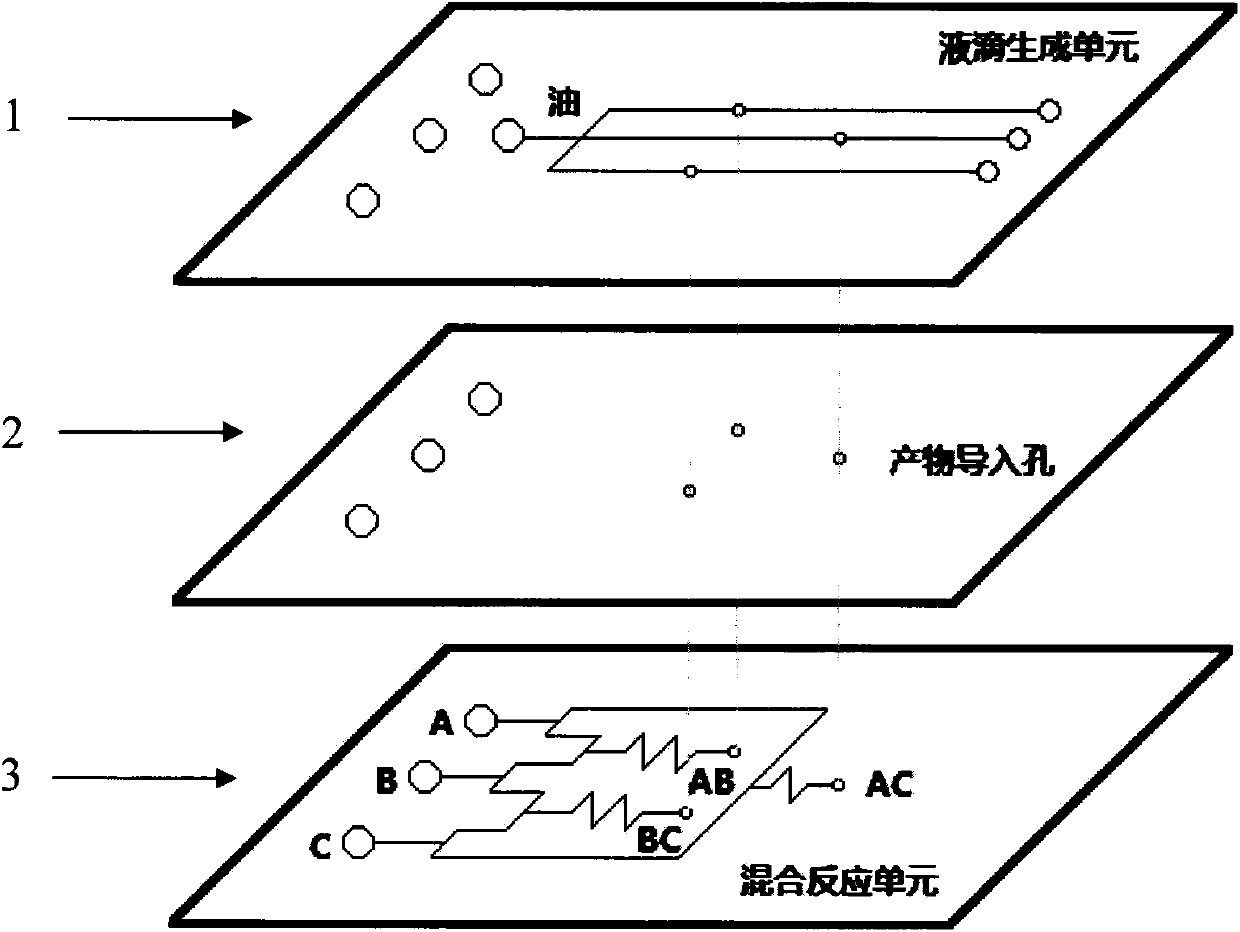

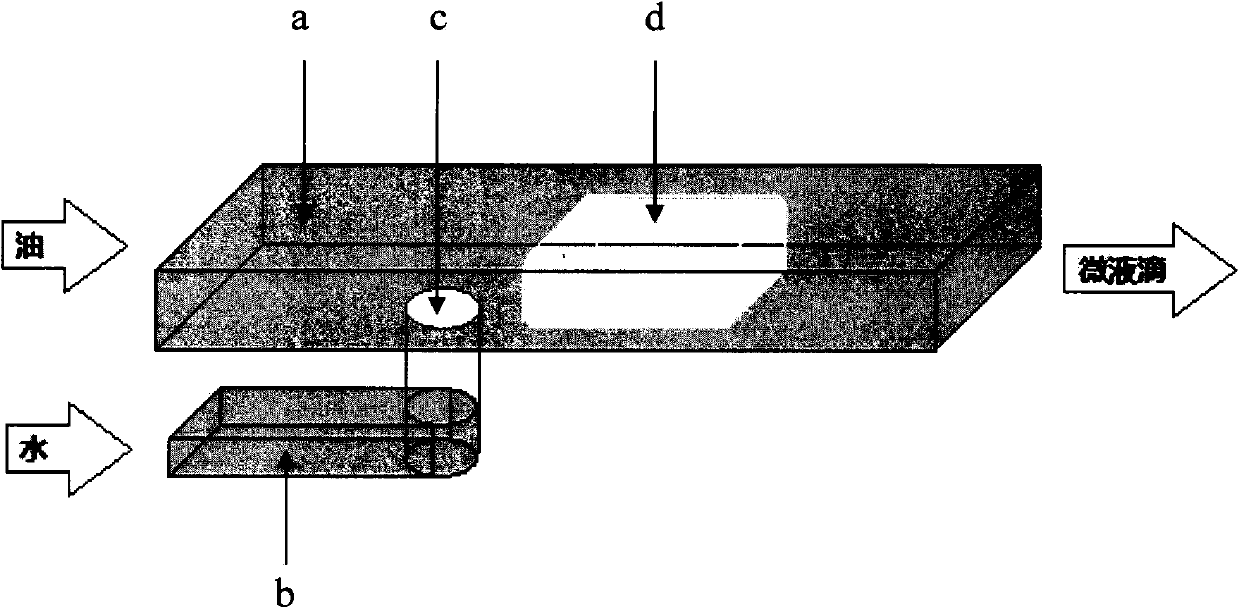

[0017] In order to realize mass production of micro-droplets with different components, the present invention proposes a microfluidic chip for producing concentration-gradient micro-droplets, which is prepared from PDMS. Such as figure 1 As shown, the microfluidic chip is composed of three parts, which are droplet production unit 1, product introduction hole 2 and sample mixing and reaction unit 3. Among them, the droplet generation unit 1 is mainly composed of the oil phase inlet and channel, and the droplet outlet; the sample mixing and reaction unit 3 is composed of different sample inlets, and two channels for mixing and mixing; between 1 and 3, the product The introduction hole 2 is connected.

[0018] When the above-mentioned microfluidic chip is used for droplet preparation, different sample solutions A, B, and C are passed into the sample holes in the sample mixing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com