Waveform furnace pipe spinning forming process

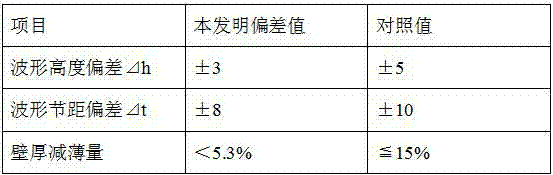

A technology of spinning forming and corrugated furnace, which is used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large cylinder stress, large equipment investment, and oxidation of the surface of the cylinder, and achieve the effect of improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

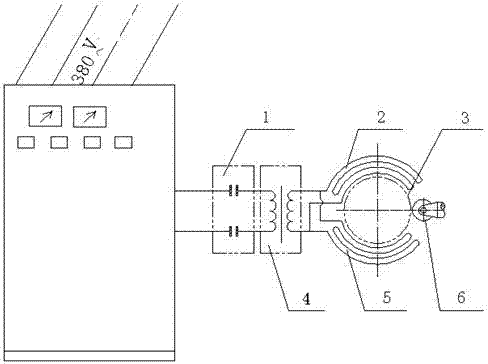

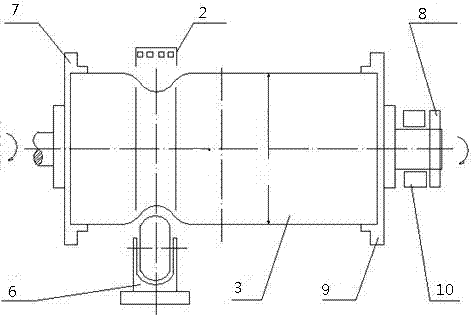

Method used

Image

Examples

Embodiment 1

[0053] Example 1: The diameter of the corrugated furnace tube section is φ726*8*2200mm

[0054] ① Given power 120KW, intermediate frequency frequency f=2500Hz, heating time: 8*1.5min / mm=12min, heating temperature: 750℃, start spinning;

[0055] ② Push the top pressure wheel to rotate one circle according to the workpiece, and push it in 2mm until the wave depth reaches the drawing requirements, then exit the top pressure wheel;

[0056] ③ After the spinning part of the cylinder section (namely the first wave node) continues to keep warm for 8 minutes, move laterally to the second wave node, and process the next wave in the same way as steps ① and ②.

Embodiment 2

[0057] Example 2: The diameter of the corrugated furnace tube section is φ1428*14*2200mm

[0058] ① Given power 160KW, intermediate frequency frequency f=2000Hz, heating time: 14*1.5min / mm=21min, heating temperature: 800℃, start spinning;

[0059] ② Press the pressing wheel to push forward and rotate one circle according to the workpiece, jacking 1.5mm until the wave depth reaches the requirements of the drawing, and exit the pressing wheel;

[0060] ③ After the spinning part of the cylinder section (namely the first wave node) continues to keep warm for 14 minutes, move laterally to the second wave node, and process the next wave in the same way as steps ① and ②.

Embodiment 3

[0061] Example 3: The diameter of the corrugated furnace tube section is φ1836*18*2200mm

[0062] ① Given power 220KW, intermediate frequency frequency f=1000Hz, heating time: 18*1.5min / mm=27min, heating temperature: 850℃, start spinning;

[0063] ② Press the pressing wheel to push in and rotate one circle according to the workpiece, and push in 1mm until the wave depth meets the requirements of the drawing, then exit the pressing wheel;

[0064] ③ After the spinning part of the cylinder section (namely the first wave node) continues to keep warm for 18 minutes, move laterally to the second wave node, and process the next wave in the same way as steps ① and ②.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com