Large-diameter circular steel tube butt joint adjusting device

A large-diameter, round steel pipe technology, applied in the field of large-diameter round steel pipe butt joint adjustment device, can solve the problems such as seamless butt joint of two-segment steel pipes, misalignment, affecting equipment performance and reliability, etc., to improve the butt joint accuracy And docking efficiency, meet the adjustment docking, scientific and simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

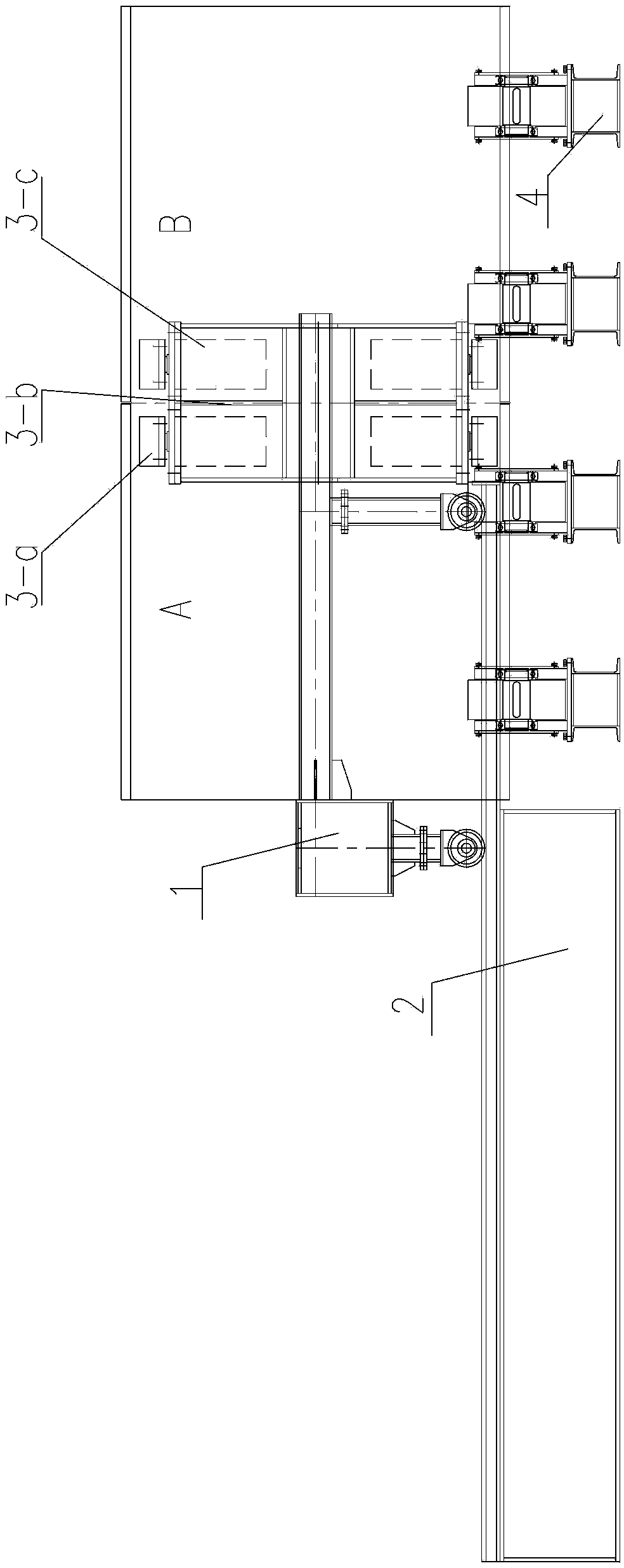

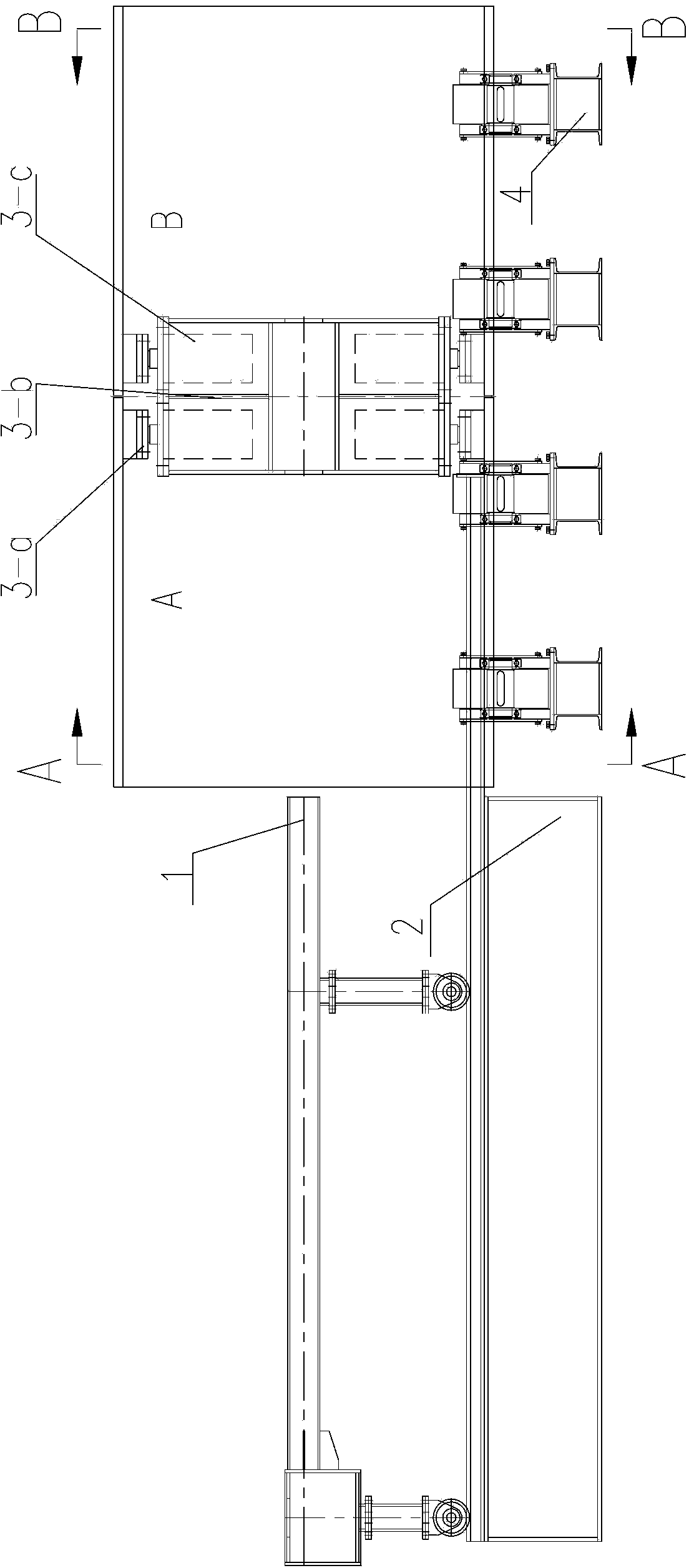

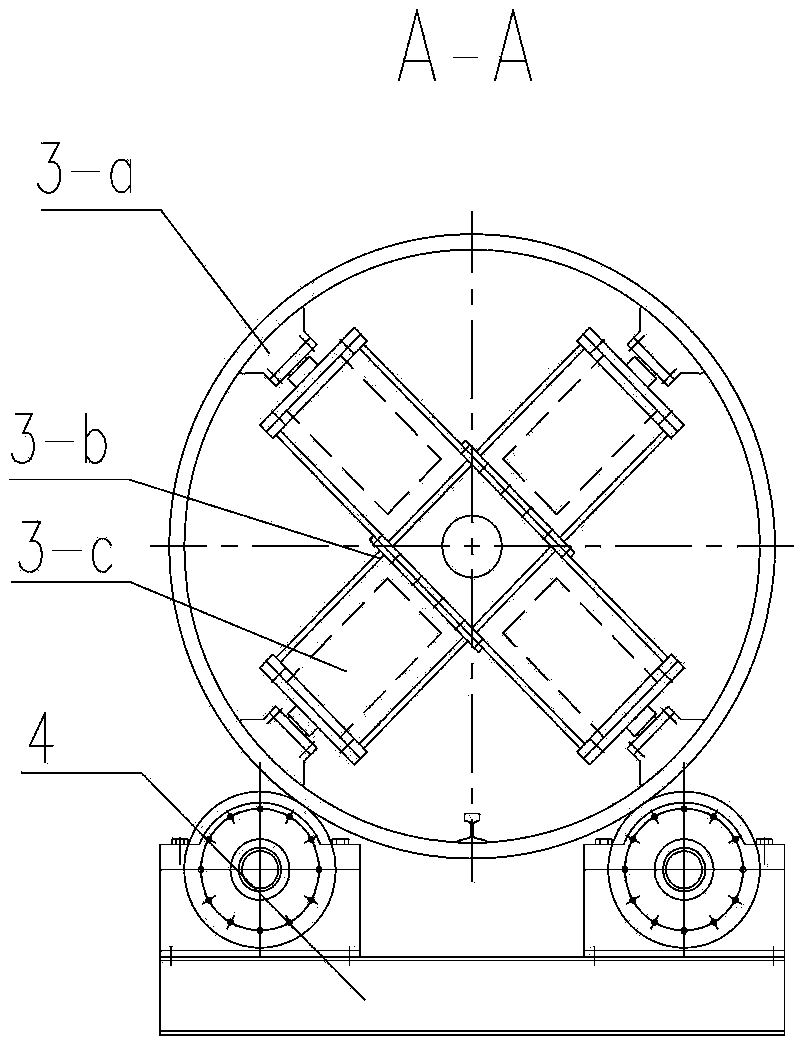

[0018] The large-diameter round steel pipe butt joint adjustment device is composed of a mobile trolley 1, a trolley mobile platform 2 and an adjustment mechanism 3. The adjustment mechanism consists of a hydraulic cylinder fixing bracket 3-b, a hydraulic cylinder 3-c, and the adjustment of the fan-shaped arc surface The pad 3-a is composed of the hydraulic cylinder fixing bracket 3-b, which is composed of two groups of left and right symmetrical cross box beams, and the left and right groups of four sets of hydraulic cylinders 3-c are respectively connected to the top panels of the left and right two groups of cross box beams. The flange plate is connected, and the ball heads of each hydraulic cylinder 3-c are respectively connected with an adjustment pad 3-a; when the adjustment mechanism is working, between two butt-connected large-diameter round steel pipes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com