Sheet extruding machine with melt pressure control system

A melt pressure and control system technology, applied in the field of sheet extruders, can solve the problems of difficulty in controlling melt pressure, influence, poor sheet quality, etc., and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

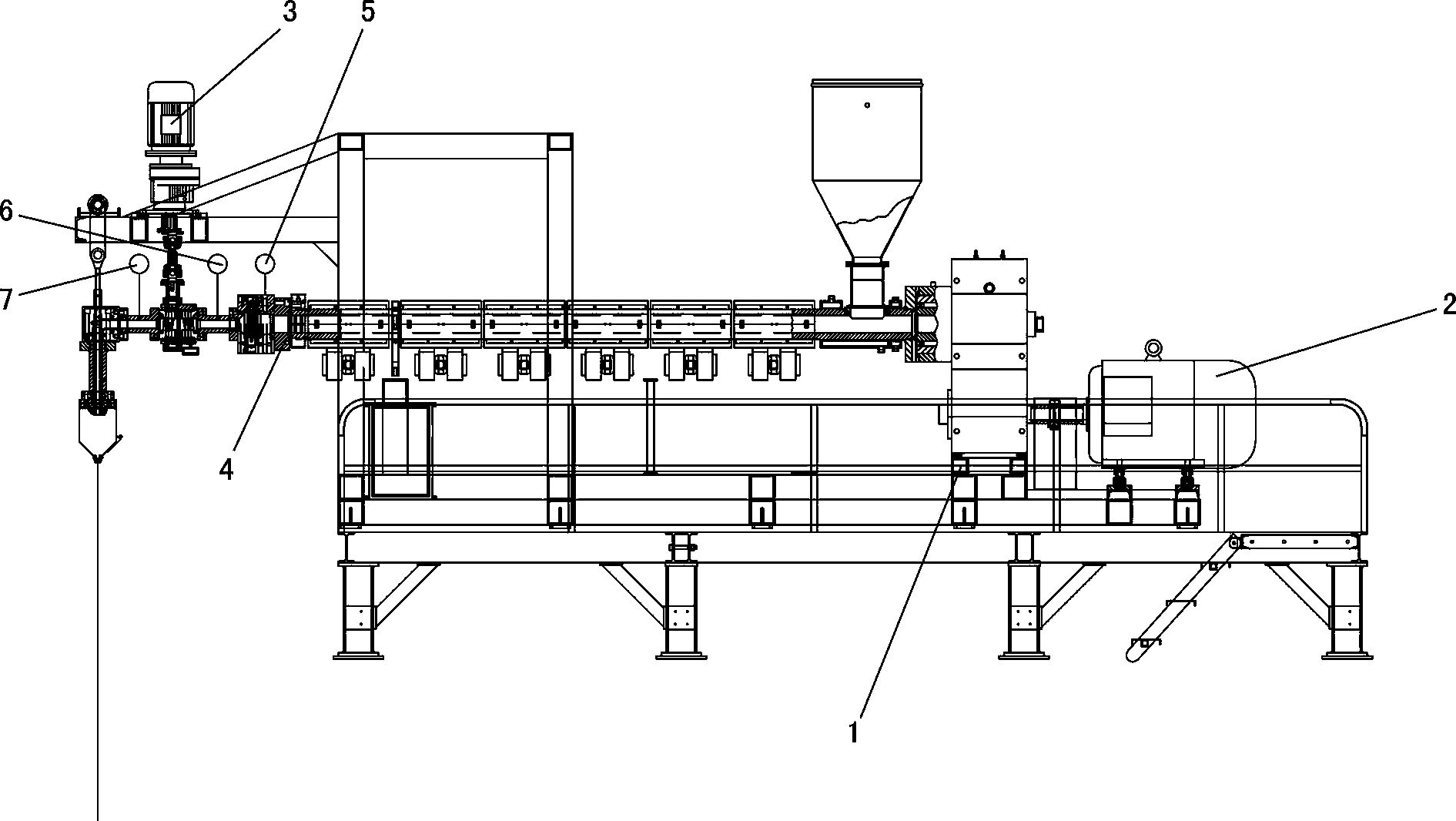

[0021] Such as Figure 1-3 As shown, the sheet extruder with the melt pressure control system in this preferred embodiment includes a fuselage 1, a host machine 2, a metering pump 3, a filter screen 4, and a melt pressure control system, and the host machine 2, metering The pump 3, the filter screen 4, and the melt pressure control system are installed on the fuselage 1 respectively.

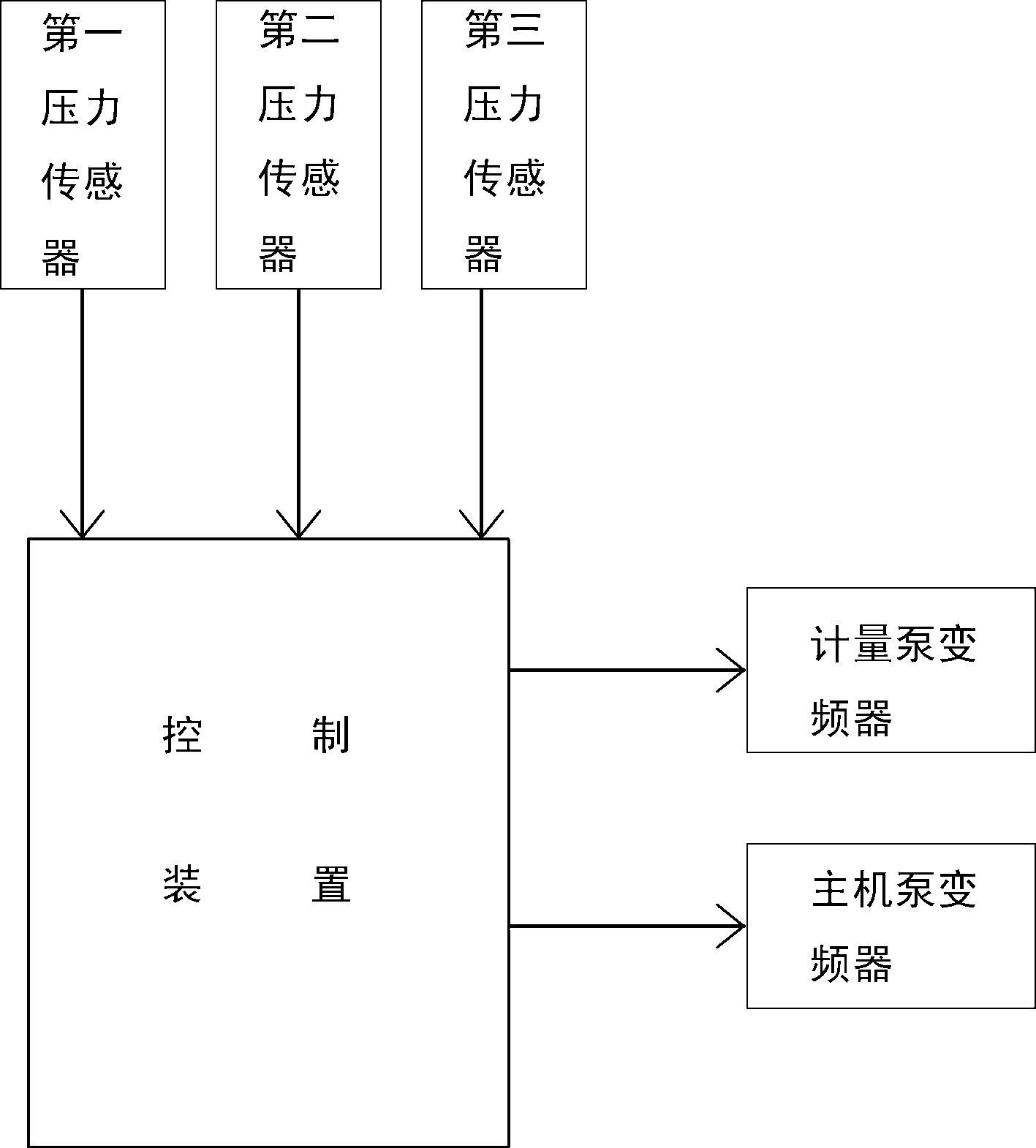

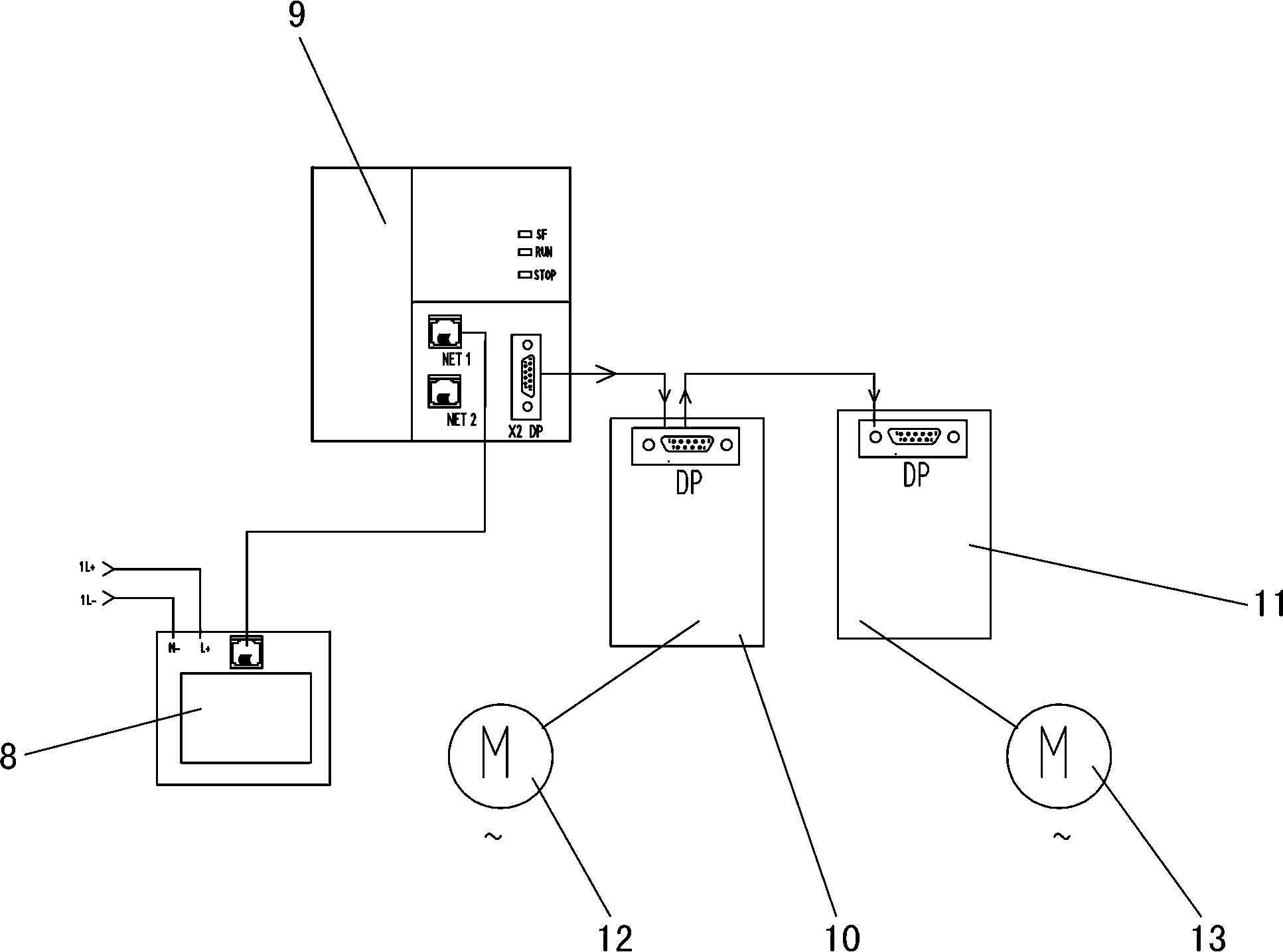

[0022] The melt pressure control system includes

[0023] The pressure detection mechanism detects the melt pressure at three places of the sheet extruder and sends out a pressure detection signal;

[0024] The control device receives and processes the pressure detection signal, and sends out the speed regulation control signal;

[0025] The speed regulating mechanism receives two speed regulating control signals and controls the speed of the corresponding driving motor.

[0026] The pressure detection mechanism includes a first pressure sensor 5, which detects the melt pressure in front of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com