Connection method for laminated circuit boards of moonlet three-line-array camera

A connection method and circuit board technology, applied in the direction of connection, circuit/collector components, circuits, etc., can solve the problems of difficult connector splicing and welding, easy interference of devices, damage to devices, etc., to improve the success rate and reliability. , the effect of reducing the quantity and reducing the cost of customization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

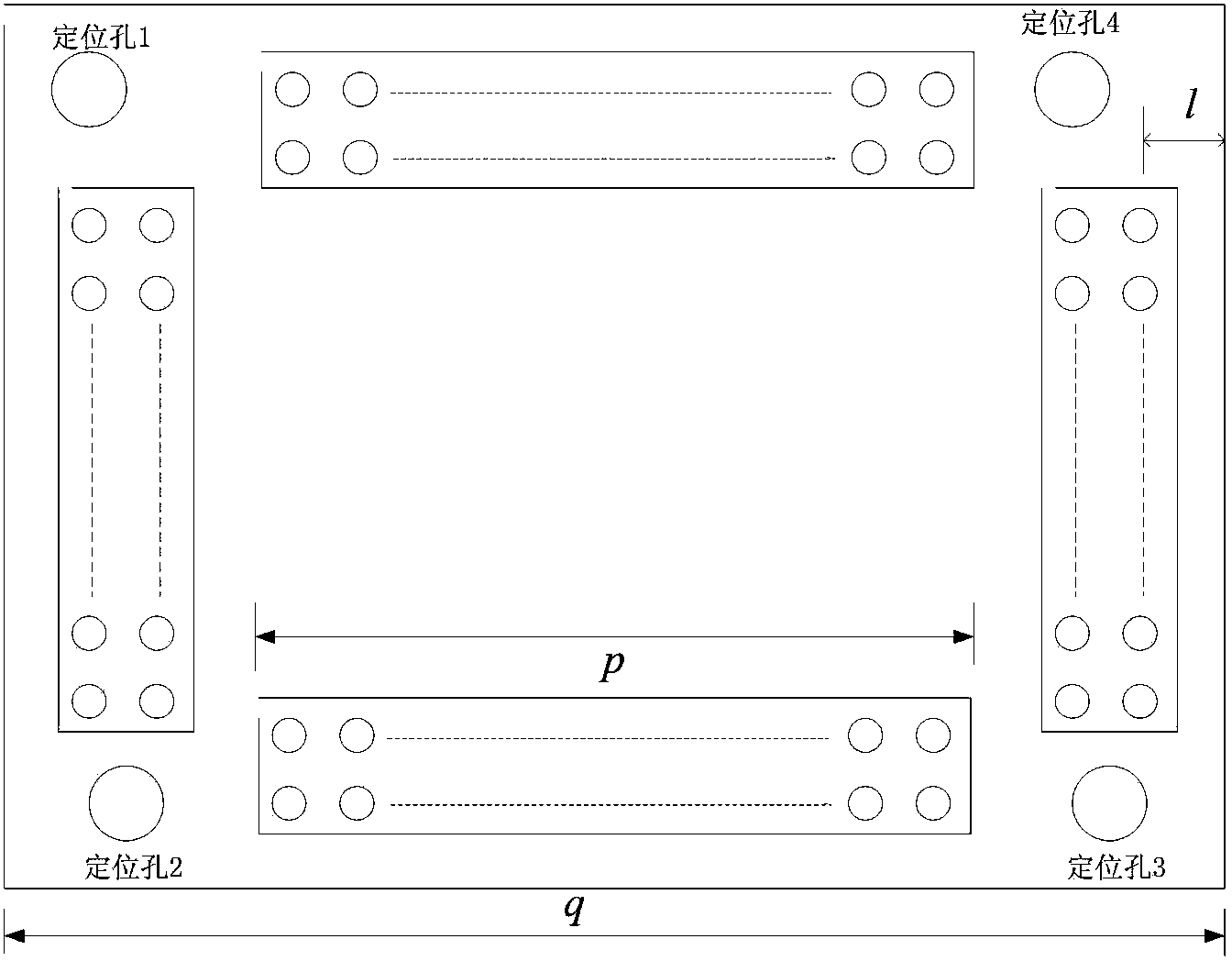

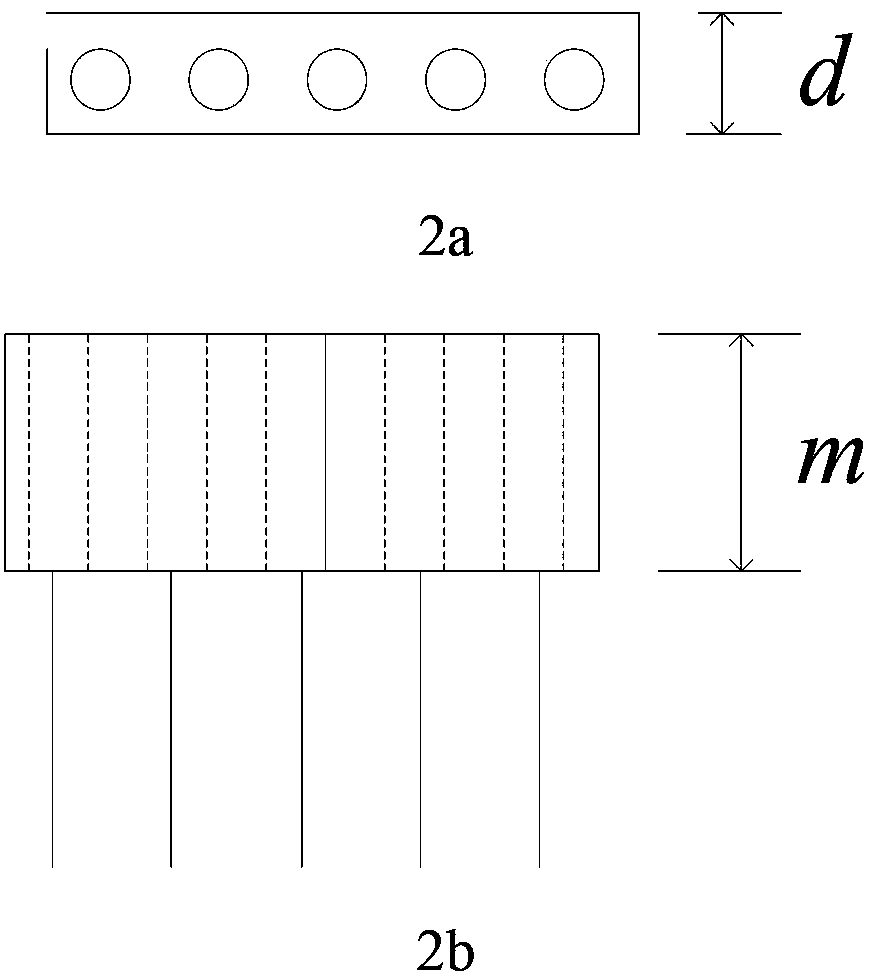

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this implementation mode, a method for connecting laminated circuit boards of a small satellite three-line array camera, the specific welding steps are:

[0016] (1) First, insert multiple connectors with a small number of single-row cores into the circuit board;

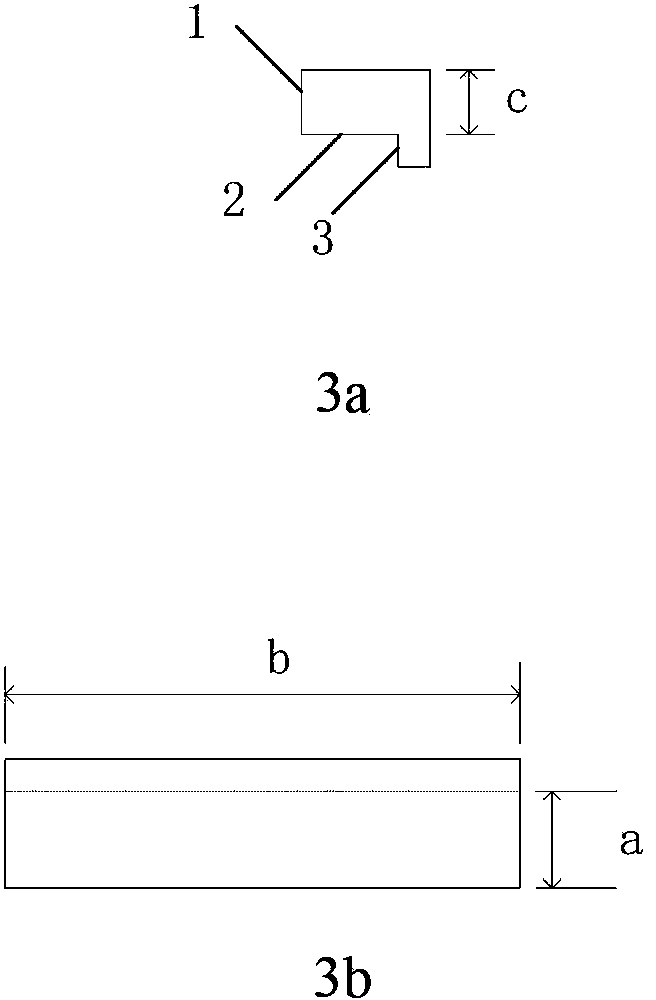

[0017] (2) Fix the socket on the upper part of the splicing connector to be welded with high-temperature-resistant standard-pitch pin tooling to ensure that the two-dimensional spacing is consistent and prevent the positioning from being affected by the deformation of the pins during the welding process;

[0018] (3) Then use high temperature resistant standard spacing protective cap tooling to fix the pins to ensure that the two-dimensional spacing of the pins is consistent;

[0019] (4) Use right-angle tooling to limit the overall verticality of the connector, and then perform manual welding. When welding, use a connector with a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com