Device for melt spinning

A technology of melt spinning and equipment, which is applied in the equipment field of composite yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

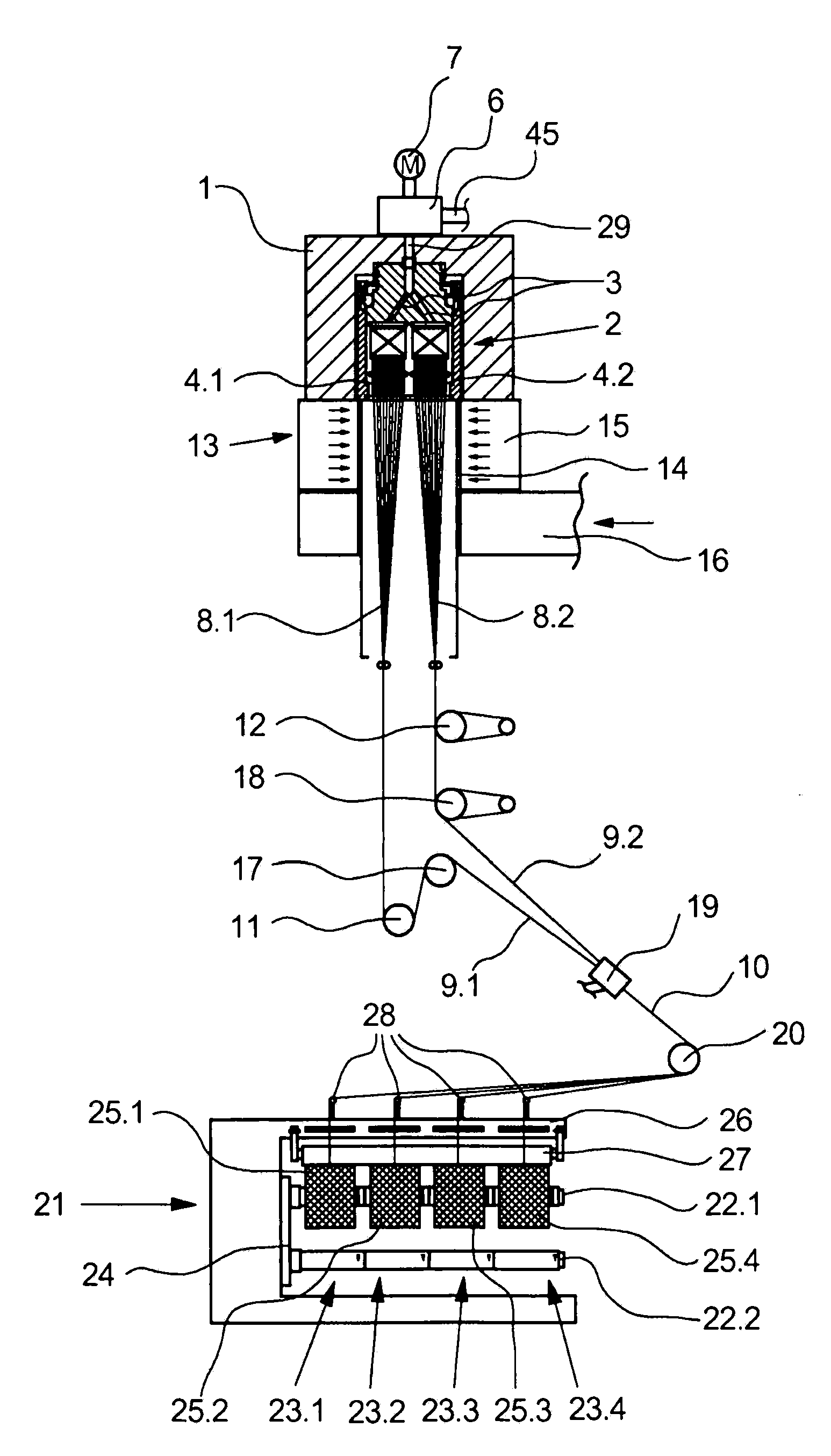

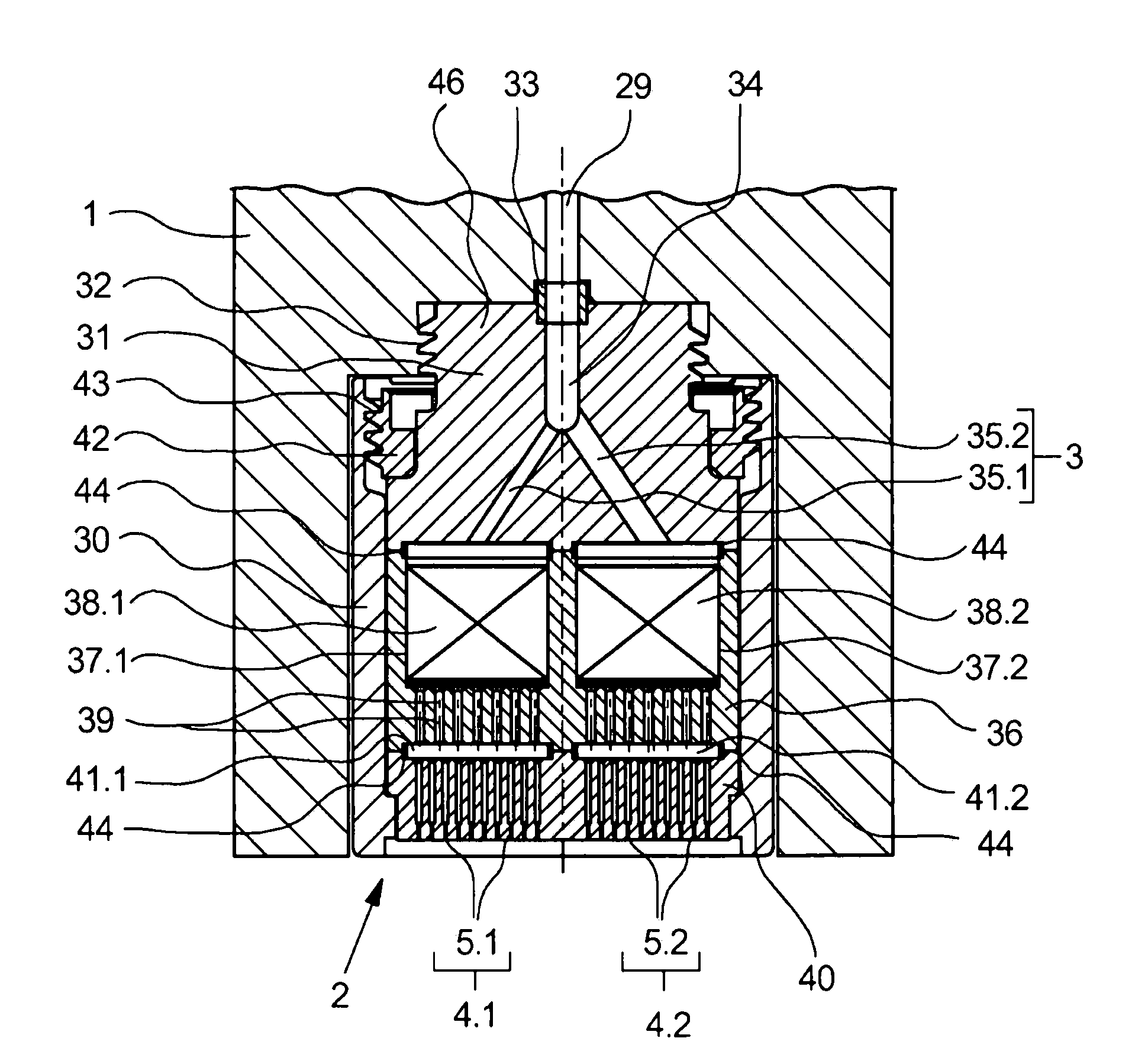

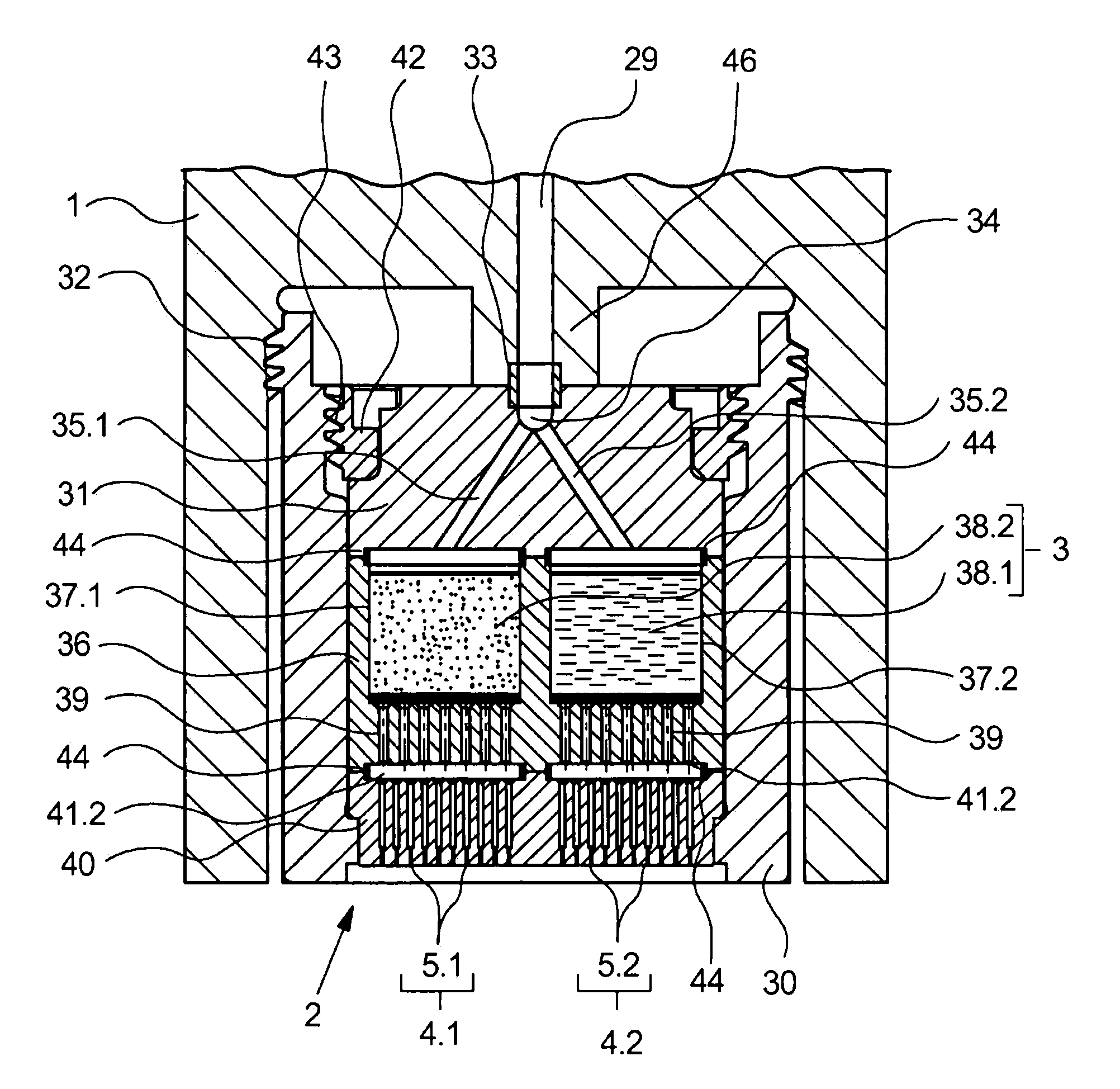

[0029] exist figure 1 , a schematic diagram of a first exemplary embodiment of an apparatus for melt spinning a composite yarn formed from a plurality of filament bundles according to the present invention is shown. An exemplary embodiment is illustrated in an operating state in which two filament bundles guided in parallel are extruded in one spinning position, stretched to form part of the filament and then Combined to form composite filaments. For this purpose, a heated nozzle support 1 is arranged in the spinning position, said nozzle support 1 supporting on the underside a spinning device in the form of a spinning nozzle arrangement 2 for extruding a plurality of filament tow. The spinning nozzle arrangement 2 has two sets of nozzle holes 4 . For this, the spinning nozzle arrangement 2 is connected to the spinning pump 6 via a melt connection 29 . On the inlet side, the spinning pump 6 is coupled via a melt inlet 45 to a melt source (not shown here), for example an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com