Underground coal mine externally-hung type shutter air window and adjusting system and method of underground coal mine externally-hung type shutter air window

A louver wind, external hanging technology, applied in mine/tunnel ventilation, special equipment for doors/windows, windows/doors, etc., can solve the problems of low air volume adjustment accuracy, air volume oscillation, real-time adjustment, etc., and achieve precise control of roadways Air volume, meet the ventilation requirements, and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

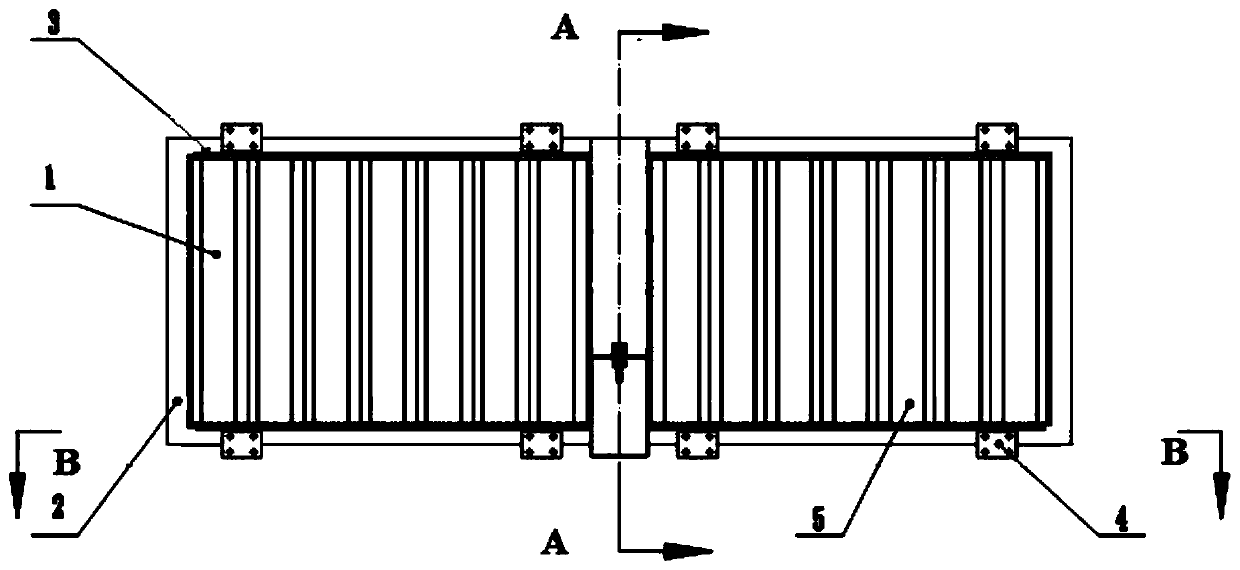

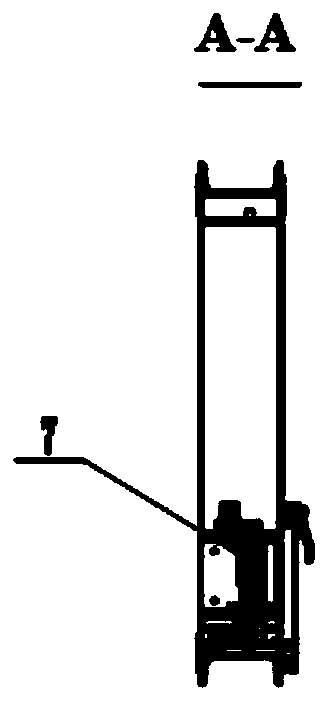

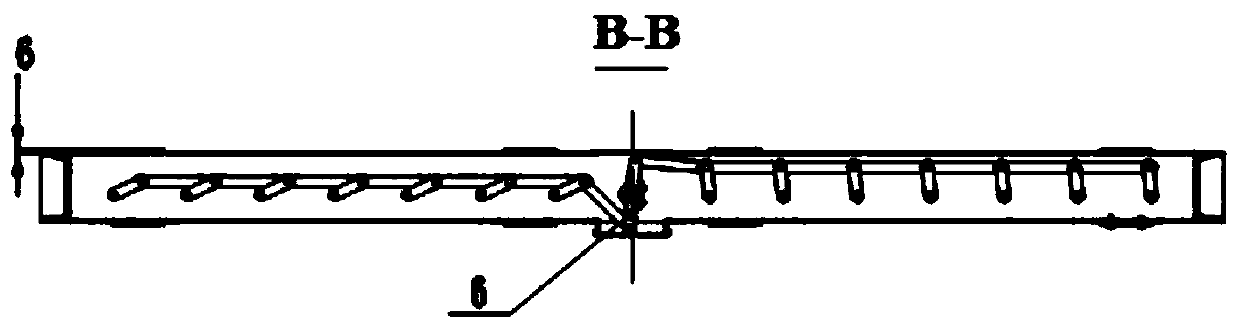

[0034] refer to Figure 1-4 , an externally hung shutter windshield in a coal mine, comprising a windshield outer frame 2, a windshield inner frame 3, a fixed plate 4, a movable sash 5, a connecting rod mechanism 6, and a pneumatic control assembly 7, the windshield outer frame 2 and the windshield outer frame 2 The windshield inner frame 3 is a frame structure, the windshield inner frame 3 is embedded in the windshield outer frame 2, the upper and lower ends of the movable sash 5 are fixed with a rotating shaft 9, and the rotating shaft 9 is set There is a shaft sleeve 8, the rotating shaft 9 is connected with the crank handle 10, a pneumatic control assembly 7 is fixed in the middle of one side of the windshield outer frame 2, and both sides of the windshield inner frame 3 are equidistant along the middle line There are several movable sashes 5 distributed, and the adjacent movable sashes 5 are connected by crank handles 10, the pneumatic control assembly 7 is connected with...

Embodiment 2

[0036] refer to Figure 1-4, an externally hung shutter windshield in a coal mine, comprising a windshield outer frame 2, a windshield inner frame 3, a fixed plate 4, a movable sash 5, a connecting rod mechanism 6, and a pneumatic control assembly 7, the windshield outer frame 2 and the windshield outer frame 2 The windshield inner frame 3 is a frame structure, the windshield inner frame 3 is embedded in the windshield outer frame 2, the upper and lower ends of the movable sash 5 are fixed with a rotating shaft 9, and the rotating shaft 9 is set There is a shaft sleeve 8, the rotating shaft 9 is connected with the crank handle 10, a pneumatic control assembly 7 is fixed in the middle of one side of the windshield outer frame 2, and both sides of the windshield inner frame 3 are equidistant along the middle line There are several movable sashes 5 distributed, and the adjacent movable sashes 5 are connected by crank handles 10, the pneumatic control assembly 7 is connected with ...

Embodiment 3

[0038] refer to Figure 1-4 , an externally hung shutter windshield in a coal mine, comprising a windshield outer frame 2, a windshield inner frame 3, a fixed plate 4, a movable sash 5, a connecting rod mechanism 6, and a pneumatic control assembly 7, the windshield outer frame 2 and the windshield outer frame 2 The windshield inner frame 3 is a frame structure, the windshield inner frame 3 is embedded in the windshield outer frame 2, the upper and lower ends of the movable sash 5 are fixed with a rotating shaft 9, and the rotating shaft 9 is set There is a shaft sleeve 8, the rotating shaft 9 is connected with the crank handle 10, a pneumatic control assembly 7 is fixed in the middle of one side of the windshield outer frame 2, and both sides of the windshield inner frame 3 are equidistant along the middle line There are several movable sashes 5 distributed, and the adjacent movable sashes 5 are connected by crank handles 10, the pneumatic control assembly 7 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com