Pressing device for presser

A material pressing device and press machine technology, which is applied in the direction of presses, manufacturing tools, etc., can solve the problems of small pressing force, low oil/juice yield, and small single pressing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

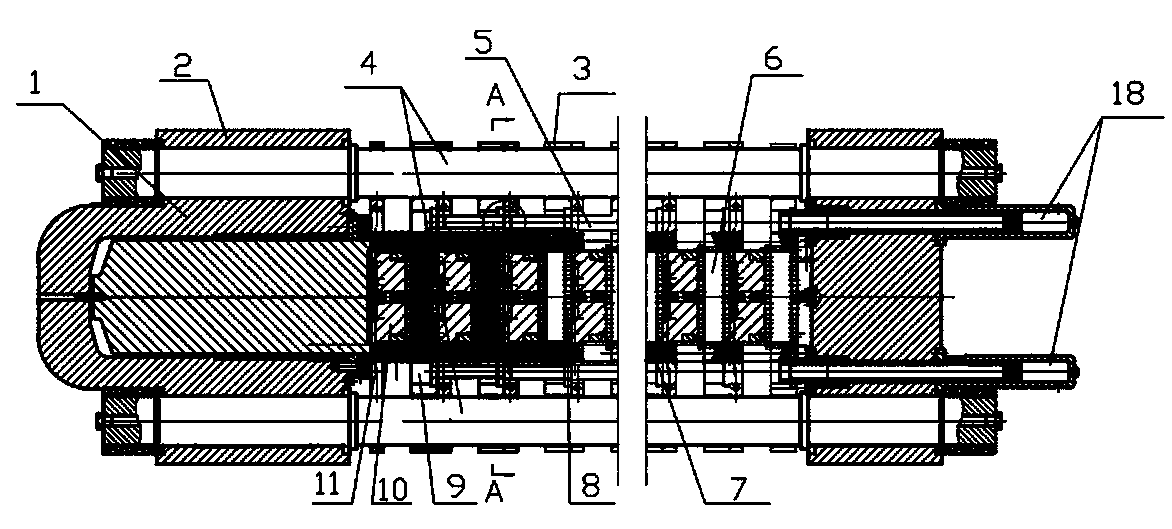

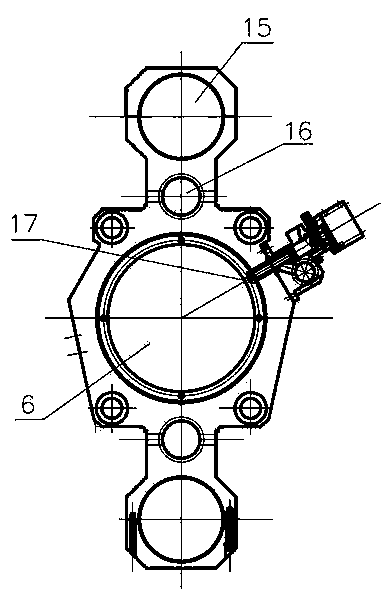

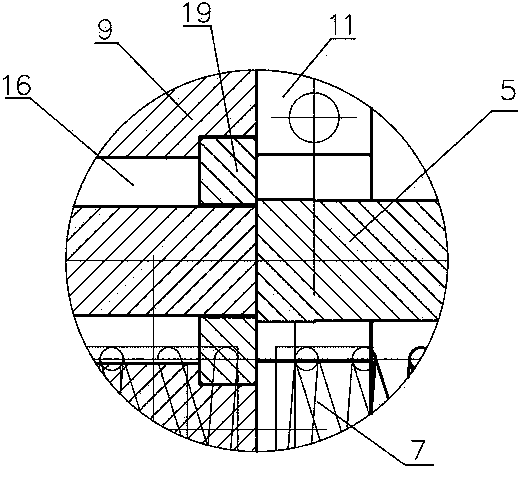

[0016] Such as figure 1 and figure 2 As shown, the pressing device for press of the present invention comprises a base, and two upper supports 2 are arranged on the base, and a main oil cylinder 1 and an auxiliary oil cylinder 18 are respectively installed on the two upper supports 2, and the main oil cylinder 1 and the piston rod of auxiliary oil cylinder 18 are parallel and opposite. Two guide rods 4 are arranged between the two upper brackets 2 , the axial directions of the guide rods 4 are parallel and their two ends are respectively fixed on the two upper brackets 2 . Fourteen pressure plates 11 and fourteen material holding plates 9 are arranged between the two upper supports 2, and the pressure plates 11 and material holding plates 9 are arranged alternately. Both radial sides of the pressure plate 11 are processed with radially outer flanges 3, the radially outer flanges 3 are processed with outer rod holes 15, and the inner sides of the two outer rod holes 15 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com