Intelligent squeezer

A pressing machine, intelligent technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as low production efficiency, difficulty in improving production efficiency, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

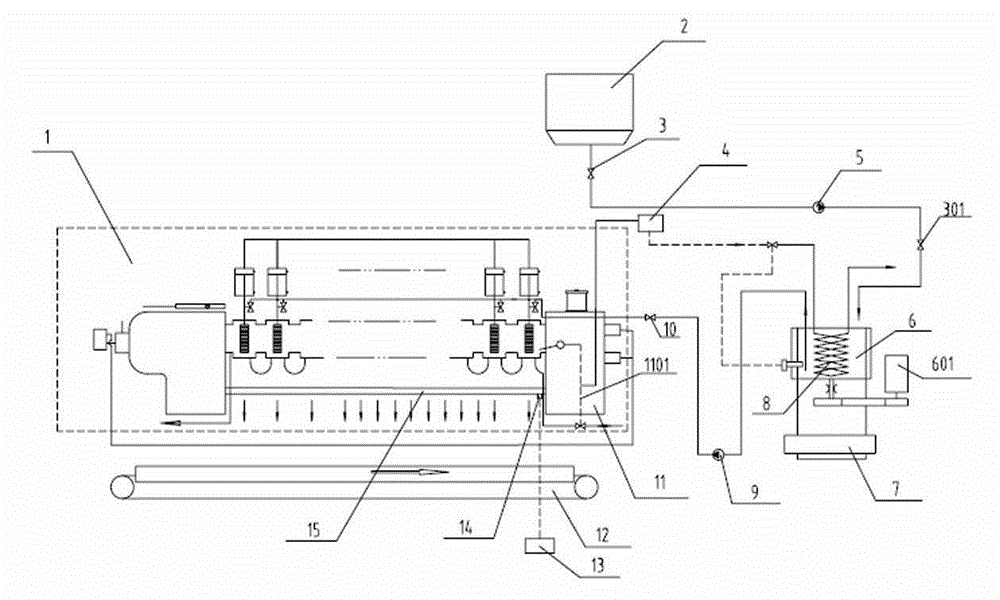

[0023] Such as figure 1 As shown, the intelligent press machine of the present invention includes a press machine body 1, a feed bin 2, a mixing drum and a controller. The silo 2 communicates with the inlet of the mixing drum through the feeding valve 3 and the first feeding pump 5. The mixing drum contains a cylinder 6 for containing the slurry, and there is an agitator 601 for mixing materials in the cylinder 6. There is a weighing device 7 for measuring at the bottom of the cylinder body 6 . There is a second steam heating device 1101 and a second temperature controller in the overflow cylinder 11. The second steam heating device 1101 communicates with the steam outlet of a boiler 4 by means of a pipeline, and the second temperature controller communicates with the steam outlet of a boiler 4 by means of a wire. The controller is connected.

[0024] The outlet of the mixing drum communicates with the press machine body 1 by means of the second feed pump 9 and the slurry in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com