Tightening device, tightening binding tie assembly and packing box

A fastening device and cable tie technology, applied in the directions of packaging, transportation and packaging, flexible elongated elements, etc., can solve the problems of inability to reuse, damage, time-consuming and laborious packaging and unpacking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

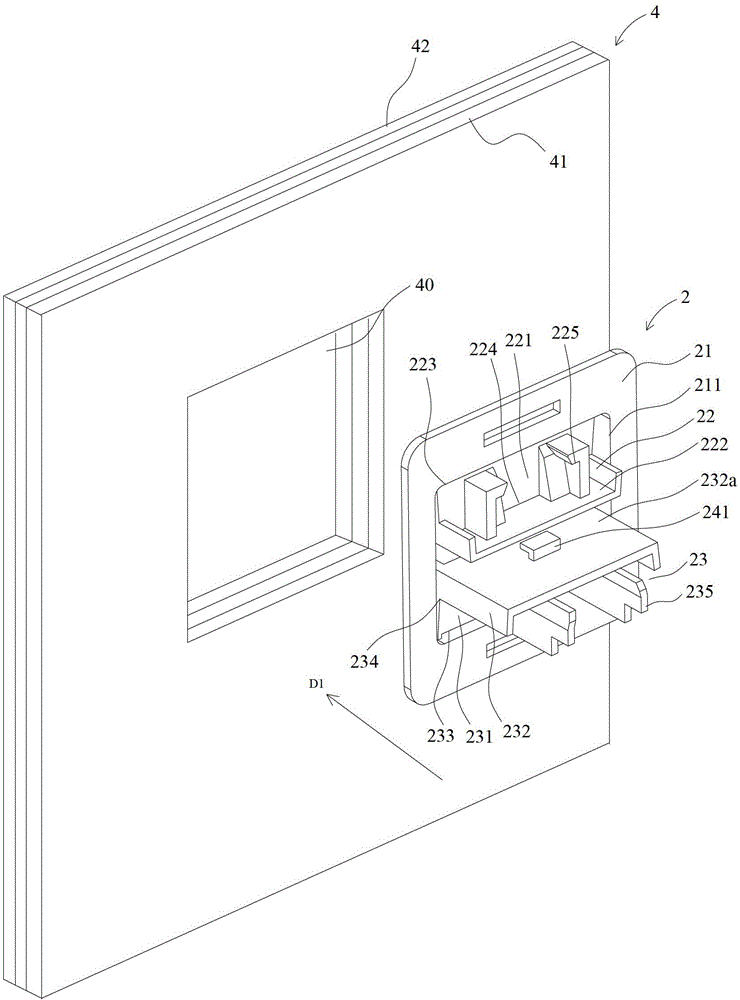

[0048] figure 2 A schematic diagram showing that the fastening device provided in this embodiment is in an open state, image 3 for figure 2 A schematic diagram of another perspective of the fastening device in , Figure 4 for figure 2 Schematic rear view of the fastening mechanism in ; see also Figure 2 to Figure 4 , figure 2 At the same time, it shows a plurality of sheets 4 to be clamped from the first direction D1. It should be noted that, in practice, the body to which the above-mentioned sheets 4 belong can be any kind of sheet with multiple layers in a certain area and needs to The clamped object is therefore in figure 2 The plate 4 shown in can be only a part of the main body having the plate 4, and the number of multiple plates 4 is not limited to figure 2 The 3 layers shown in , may also be 2 layers or any number greater than 3 layers.

[0049] exist figure 2 Among them, a plurality of sheets to be clamped form buttonholes 40 penetrating along the fir...

Embodiment 2

[0072] In the fastening device 2 in the above embodiment, the cable tie hook 241 is only formed on the locking seat 23 of the fastening device 2. In practice, the cable tie can also be formed only on the hook seat 22 of the fastening device 2. With a hook, now the two ends of the cable tie can be hooked on the cable tie hook on the hook seat 22, when the fastening device is switched from the open state to the fastened state, the cable tie can also be hooked tension. In addition, a cable tie hook can also be provided on the hook seat 22 and the locking seat 23 of the fastening device respectively, Figure 15 to Figure 19 A structural schematic diagram of a fastening device with a cable tie hook provided on each of the hook seat and the locking seat is shown. Figure 15 to Figure 19 Winning mark and Figure 2 to Figure 12 Structures with the same number refer to the same components, which will not be repeated here.

[0073] Figure 15 A schematic diagram showing that the fas...

Embodiment 3

[0079] In practice, the cable ties all have a certain thickness, especially considering the requirement of binding strength, the thickness of the cable tie cannot be ignored in the design process of the fastening device. In the first and second embodiments, the When the fastening device 2, 2' is in the fastened state, there is a certain gap between the hook seat 22 and the locking seat 23 of the fastening device 2, 2', and the gap is used to leave a space for the cable tie , but this implementation also has a gap in addition to the position of the cable tie, so to a certain extent, it affects the sealing performance of the fastening device 2, 2' in the fastened state. The fastening device in this embodiment is in the A further improvement is made here. When the hook seat 22 and the locking seat 23 swing to the position of the buckled state, at least one of the first base wall 221 and the second base wall 231 is opposite to each other. A gap is formed. In the following, the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com