Walking rotary multi-point unloader

The utility model relates to an unloading machine and a rotary type technology, which is applied in the field of auxiliary unloading devices, and can solve the problems of material scattering and rolling, high unloading cost and low unloading efficiency, and achieves the effects of high unloading efficiency, improved unloading efficiency and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

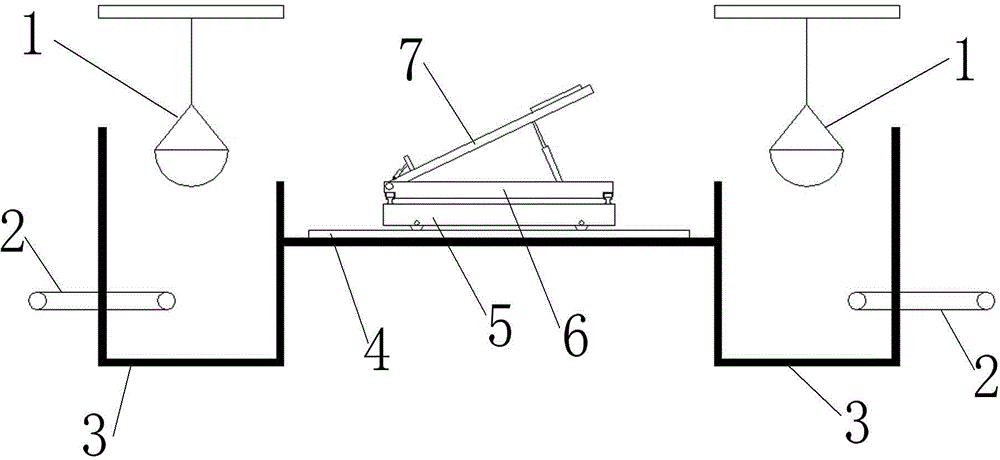

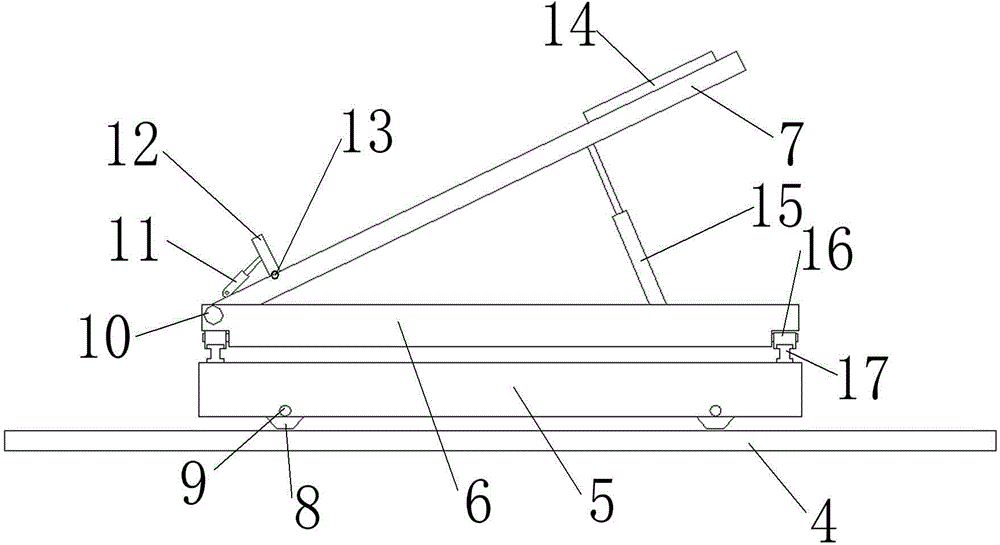

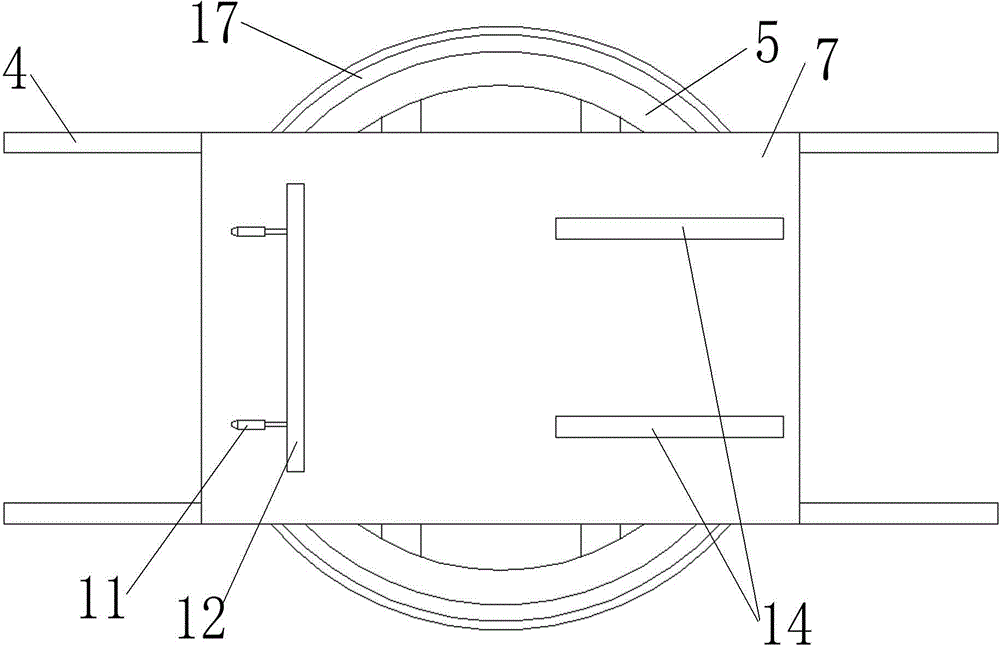

[0022] Attached below figure 1 To attach Image 6 The present invention will be further described.

[0023] as attached figure 1 As shown, the walking rotary multi-point truck unloader includes a horizontal guide rail 4 installed on the horizontal ground, two underground silos 3 arranged on the left and right sides of the horizontal guide rail 4 and located under the horizontal ground, and a horizontal guide rail 4 arranged on the The walking base 5, the rotating platform 6 arranged above the walking base 5, the turning platform 7 installed at one end of the turning platform 6 by rotating the tail end through the rotating shaft I 10, and the vehicle stop installed on the turning platform 7 to prevent the vehicle from sliding down in an inclined state device, the bottom of the walking base 5 is equipped with a walking power device to move along the transverse guide rail 4, the bottom of the rotating platform 6 is equipped with a rotating power device that makes it rotate rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com