Vehicle driven under assistance of gravity

A gravity and vehicle technology, which is applied to vehicle components, wheels, power plants, etc., can solve the problems of short battery energy mileage, time-consuming battery charging, and inconvenient car charging, and achieve small deformation, energy saving, and load reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

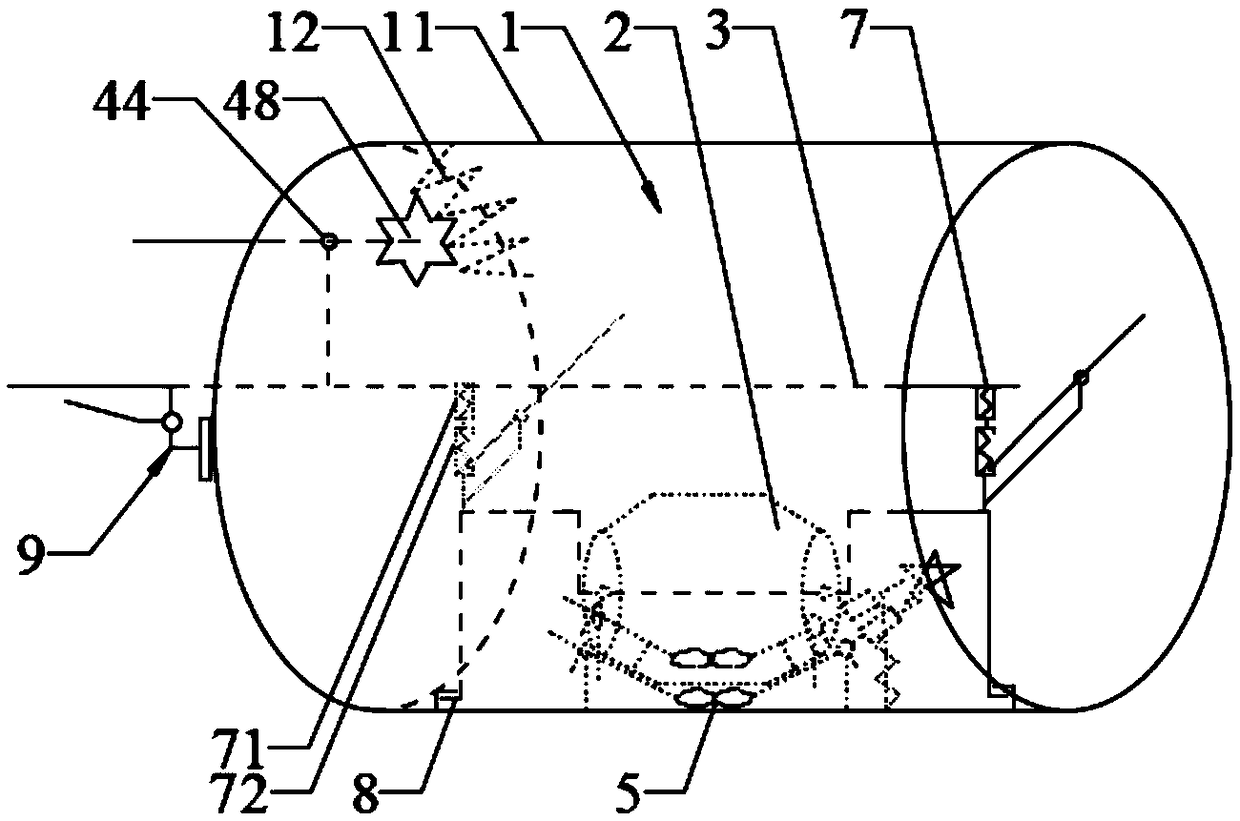

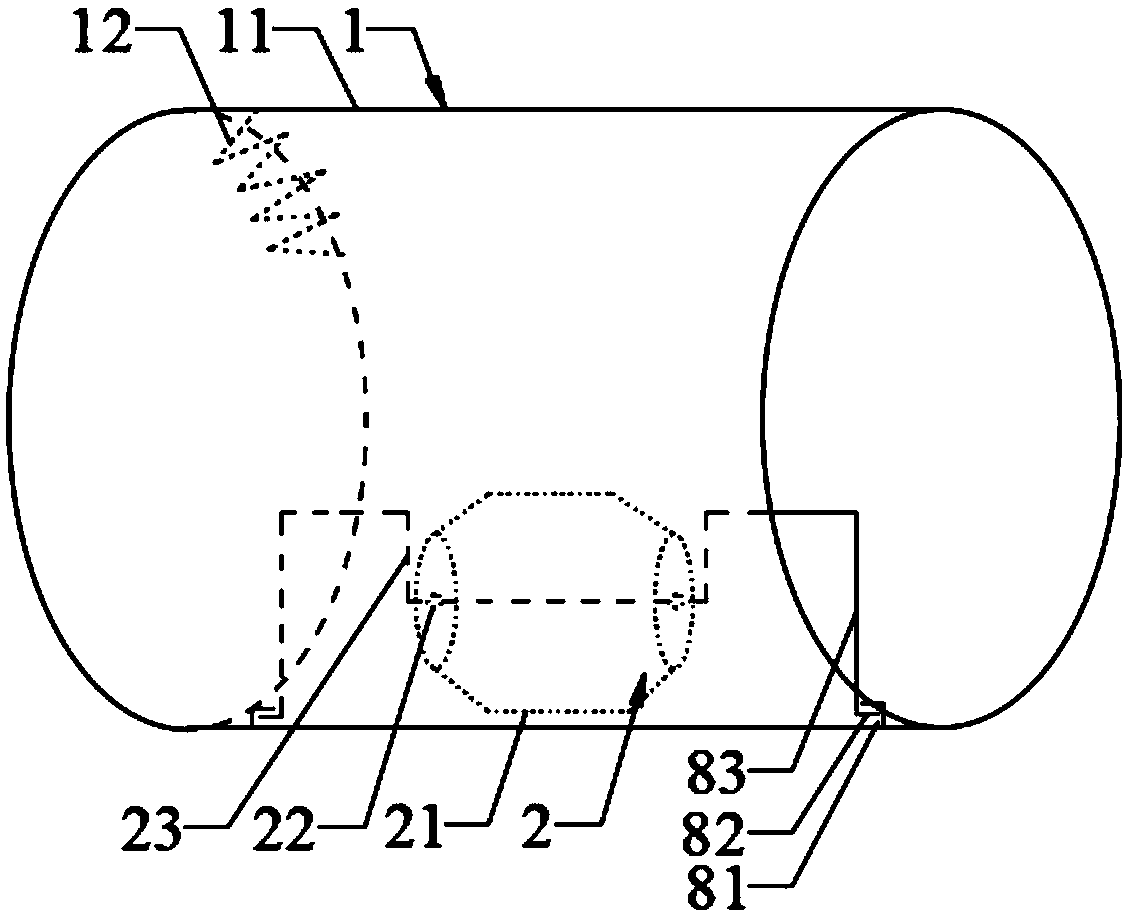

[0092] Please refer to Figure 1 to Figure 4 As shown, a vehicle utilizing gravity-assisted driving includes an outer wheel 1, an inner wheel 2, a chassis 3, an electric drive device 4, a gravity-assisted driving device 5 and a gravity transmission device 6;

[0093]Described outer wheel 1 comprises hard wheel 11 and hard wheel 11 internal teeth 12, and described hard wheel internal tooth 12 is positioned at one end of hard wheel 11 and is distributed along the inner circumference of hard wheel 11; Described inner wheel 2 comprises bearing wheel 21, bearing bearing 22 and load-bearing shaft 23, the load-bearing wheel 21 is located in the middle part of the inner side of the hard wheel 11, the end face of the load-bearing wheel 21 is provided with a central through hole, the load-bearing bearing 22 is arranged at the two ends of the central through-hole, and the load-bearing shaft 23 passes through the central through hole and is connected with load-bearing bearing 22, and the ...

Embodiment 2

[0098] Please refer to Figure 7 As shown, it is the same as other structures of the gravity-assisted vehicle in Embodiment 1, the difference is that the electric drive device 4 can be:

[0099] The electric drive device 4 includes a speed-regulating motor 41 and a drive gear 48 driven by the speed-regulating motor 41, and the drive gear 48 meshes with the hard wheel internal teeth 12;

[0100] Also comprise motor shaft gear 42, rotating shaft 43, rotating shaft bearing 44, rotating shaft bearing block 45, rotating shaft gear 46 and shaft transmission gear 47, described motor shaft gear 42 is arranged on the motor shaft of speed regulating motor 41, so The rotating shaft 43 is arranged on the chassis 3 through the rotating shaft bearing 44 and the rotating shaft bearing seat 45. The rotating shaft gear 46 is arranged on the rotating shaft 43 and meshes with the motor shaft gear 42. The gear of the shaft transmission gear 47 The shaft is arranged on the chassis 3 and the shaft...

Embodiment 3

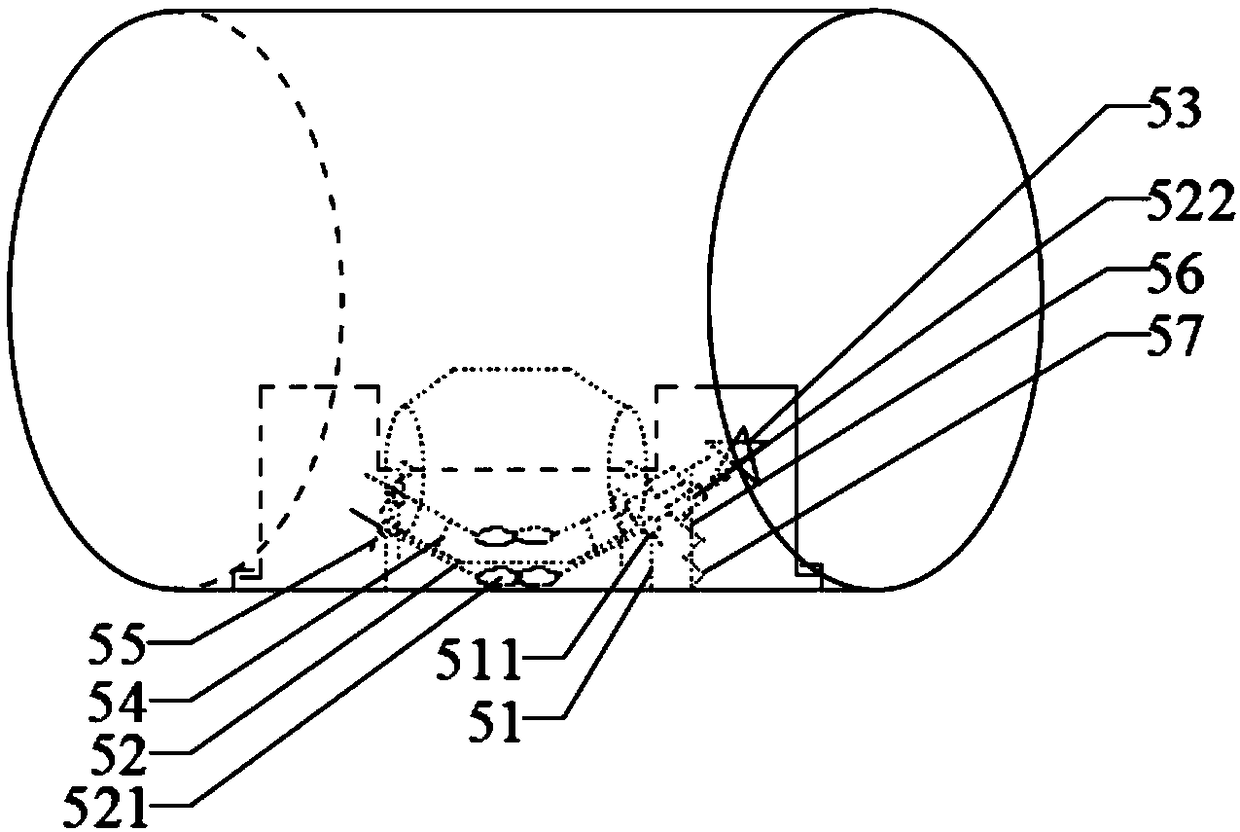

[0102] Please refer to Figure 5 with Image 6 As shown, it is the same as other structures of the gravity-assisted vehicle in Embodiment 2, the difference is that the gravity-assisted vehicle also includes a shock absorber 7, and the shock absorber 7 is arranged on the bearing shaft 23 and the chassis 3 Between, the shock absorber 7 includes a gas spring shock absorber 71 and a vibration energy utilization device 72, the upper end of the gas spring shock absorber 71 is connected to the chassis 3, and the lower end of the gas spring shock absorber 71 is connected to the vibration The upper end of the energy utilization device 72 is connected, and the lower end of the vibration energy utilization device 72 is connected to the bearing shaft 23;

[0103] Described vibration energy utilization device 72 comprises damping spring 721, the spring cover 722 with slide groove, damping rotating rod 723, damping rotating rod bearing 724 and damping rotating rod bearing shaft 725, descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com