A bearing support structure

A bearing support seat, bearing support technology, which is applied to the rigid bracket of bearing components, bearing components, shafts and bearings, etc., can solve the problems of bearing drive shaft damage, affecting bearing installation quality, etc., to ensure position accuracy and improve installation quality. , to avoid the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

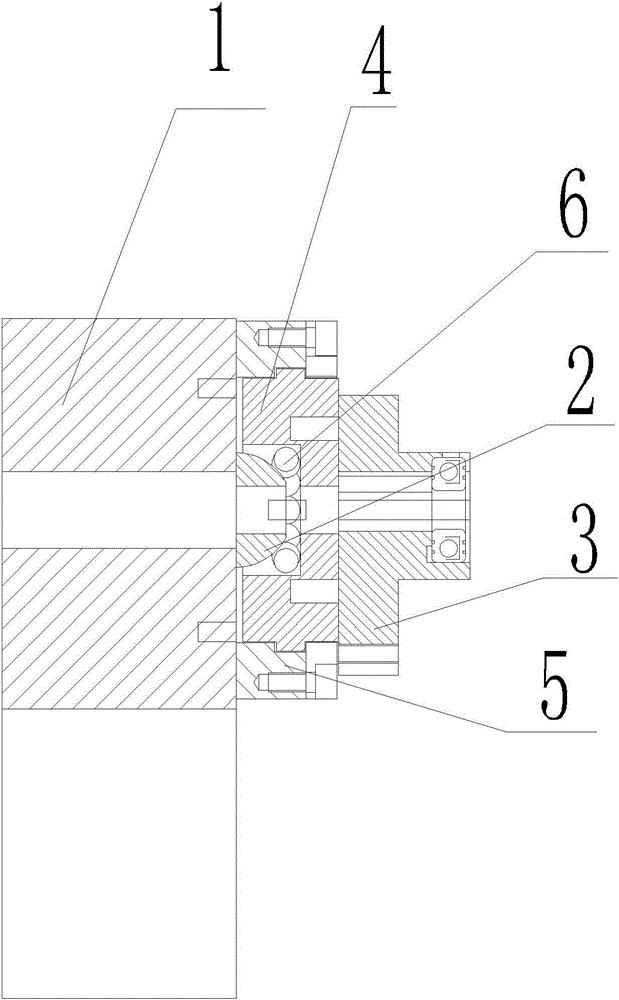

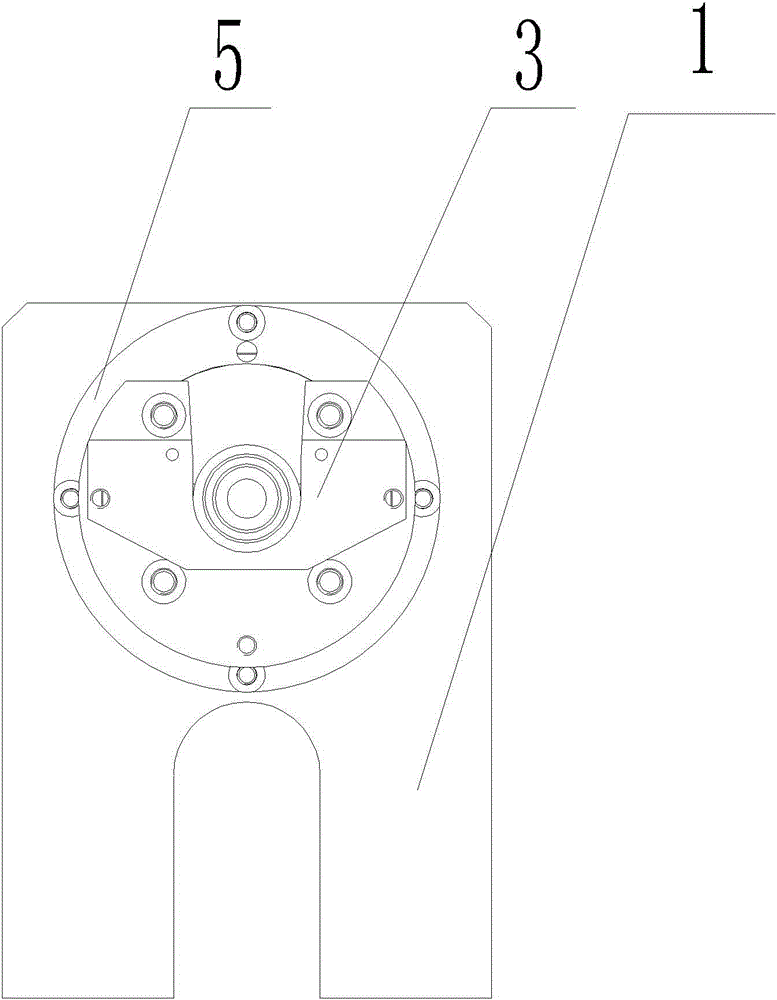

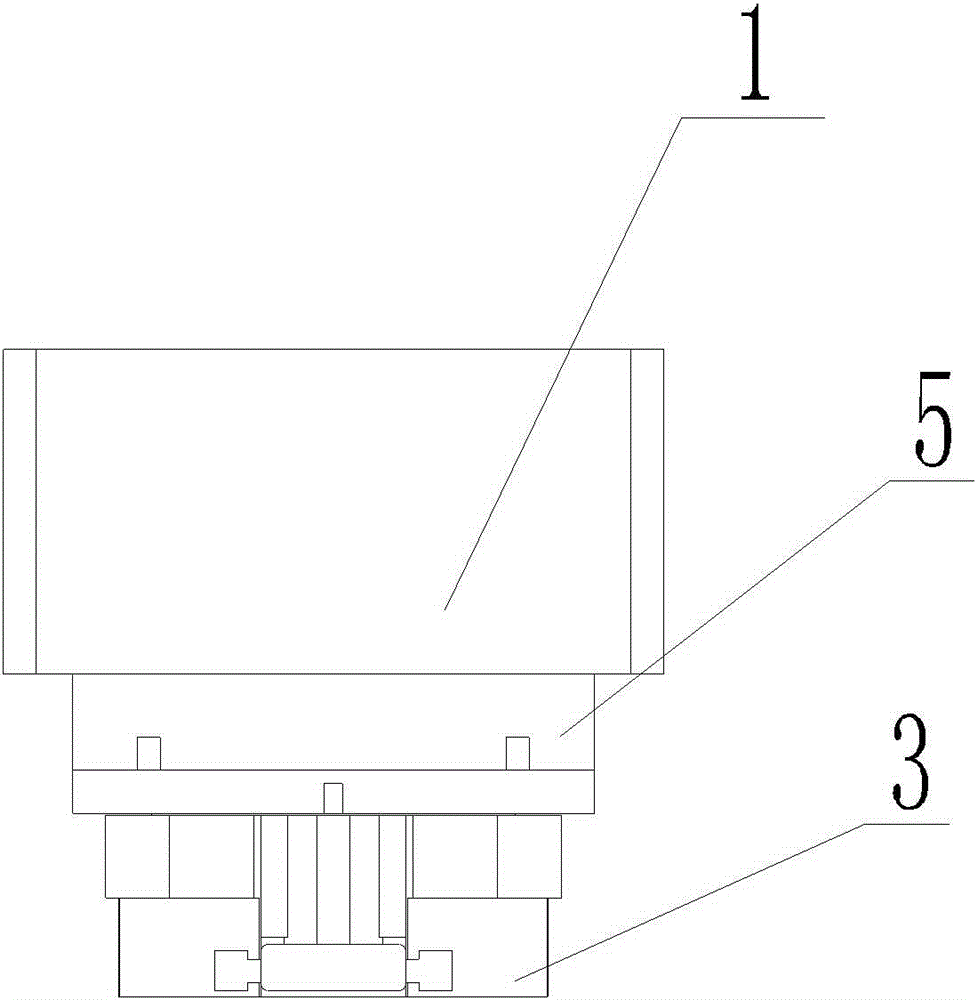

[0010] See figure 1 , figure 2 As shown, a bearing support seat structure includes a bearing support seat body 1, a hemispherical support seat 2 is arranged on the bearing support seat body 1, a bearing fixture 3 is fixed on a fixture seat 4, and the fixture seat 4 moves through a positioning sleeve 5 Connect the hemispherical support seat 2, the positioning sleeve 5 is fixed on the bearing support base body 1, the positioning sleeve 5 has a gap with the fixture seat 4, the fixture seat 4 can rotate around the hemispherical support seat 2 within a certain range relative to the positioning sleeve 5, and can When the bearing is pressed into the transmission shaft, the concentricity of the bearing and the transmission shaft is adjusted, which effectively prevents damage to the bearing or the transmission shaft.

[0011] The fixture seat 4 is connected to the hemispherical support seat 2 through the steel ball 6, which ensures the stable and reliable movement of the bearing fixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com