Mechanical connecting fastener reliability test bed with bi-directional loading simulation function

A mechanical connection and load simulation technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of axial and radial dynamic loading of fasteners, and achieve control and adjustment methods. Simple and practical, simulates real working conditions, and has a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the drawings:

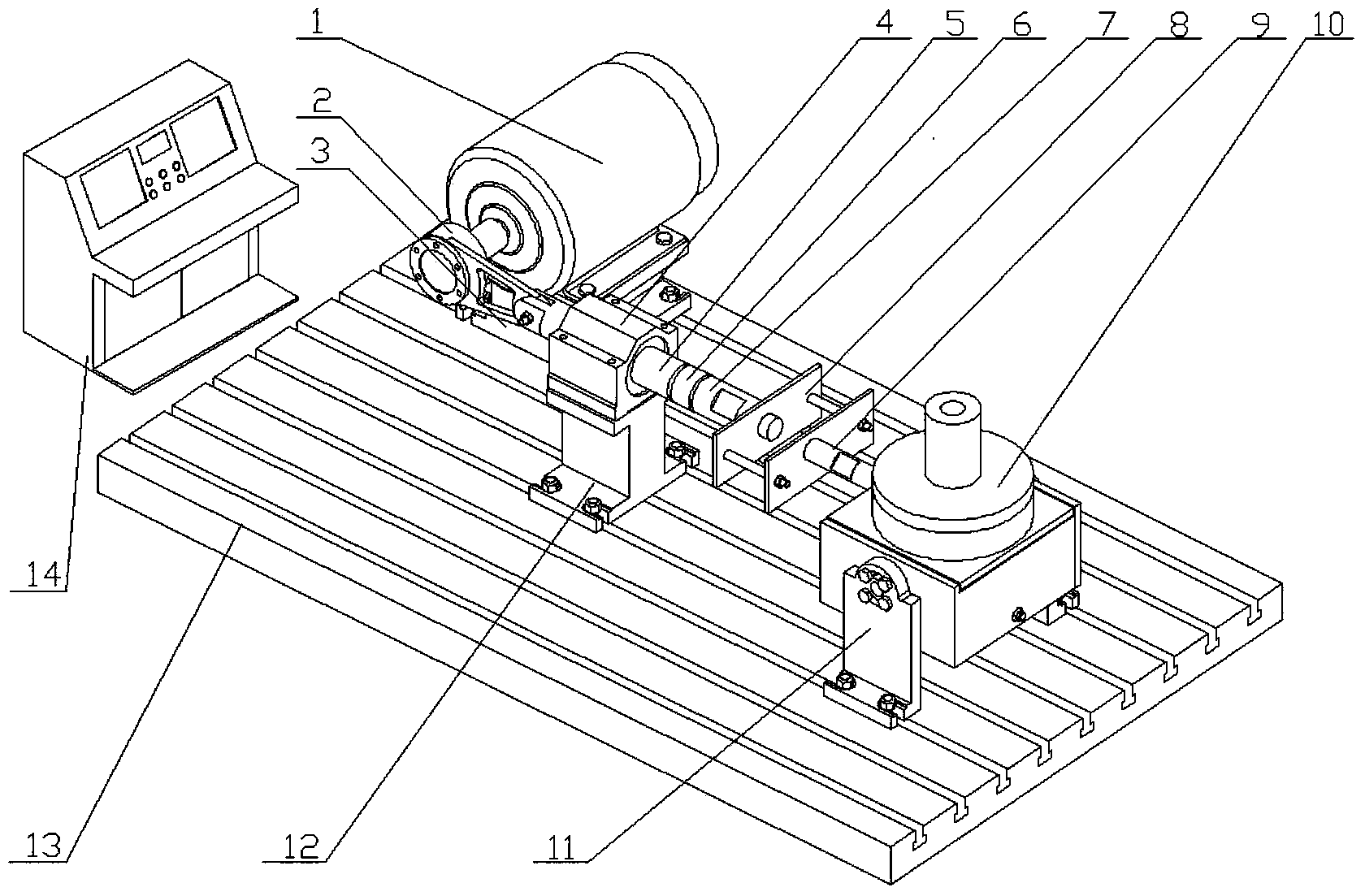

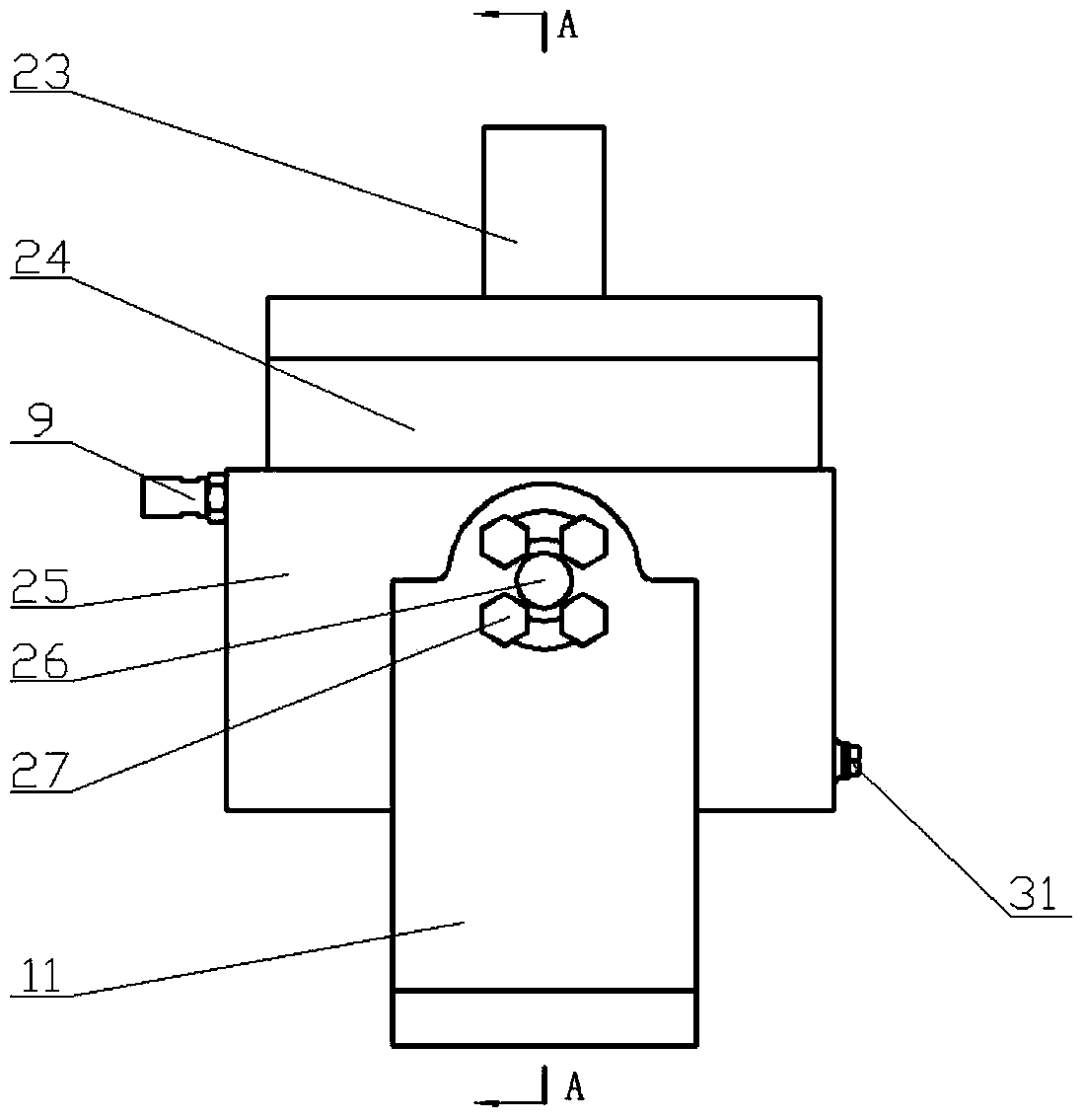

[0044] Refer to figure 1 The reliability test bench for mechanical connection fasteners with a bidirectional load simulation function of the present invention is composed of a vibration power source, a dynamic loading and measuring mechanism and a workbench mechanism.

[0045] 1. Vibration power source

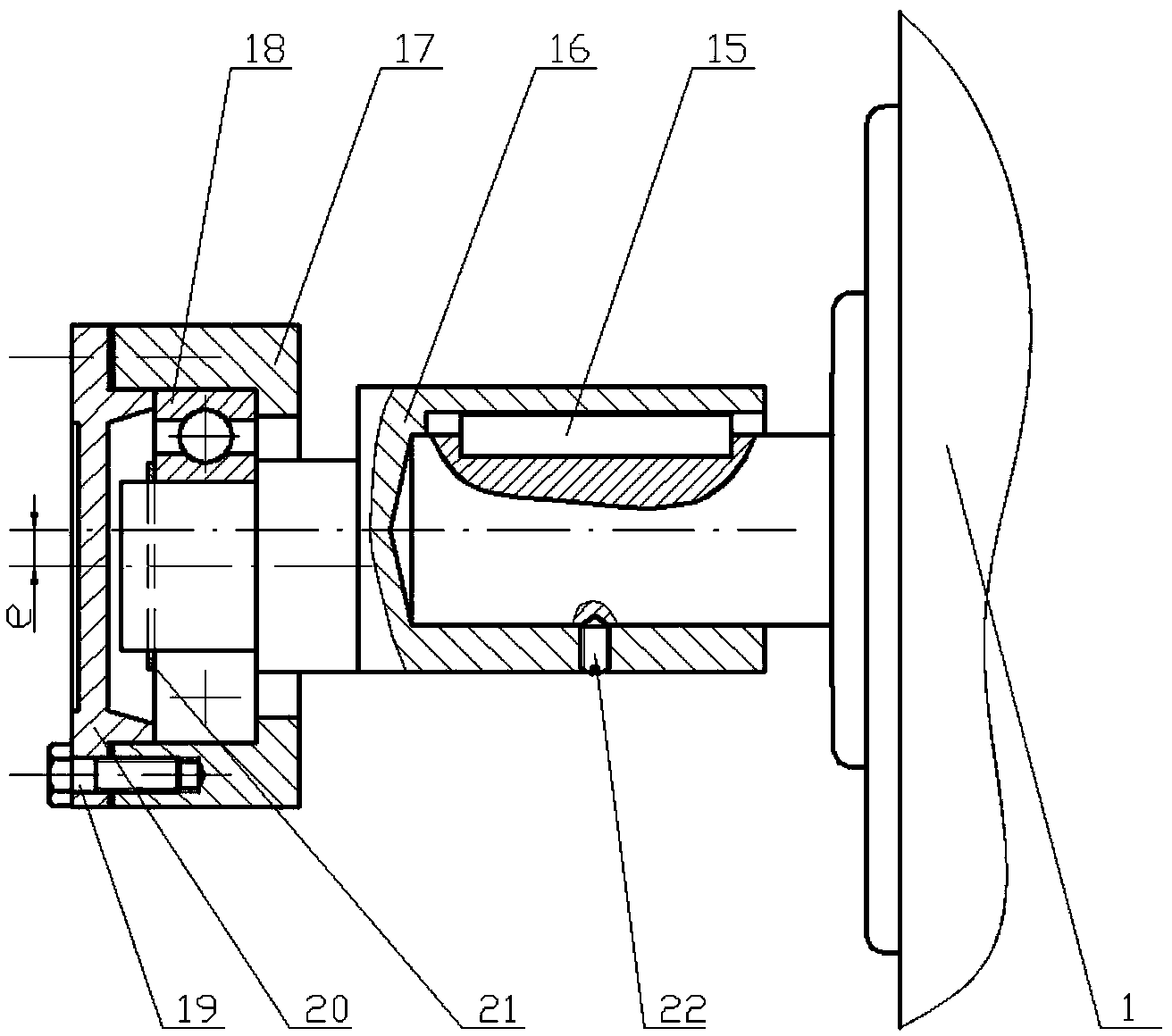

[0046] Refer to figure 1 with figure 2 The said vibration power source includes three-phase asynchronous motor, motor bracket, frequency converter, eccentric sleeve, flat key, connecting rod, deep groove ball bearing, screw (6), end cover, elastic retaining ring for shaft and tightening Composed of screws.

[0047] The motor bracket 3 is shaped like an "I" in cross section, with threaded holes on the upper plane and four U-shaped grooves on the lower plane for fixing on the ground iron 13; the eccentric sleeve 16 is a three-stage Stepped shaft, the axis of the first two steps of steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com