Disinfecting tank with nozzle structure

A technology for disinfection pools and nozzles, applied in the direction of chemistry, etc., can solve the problems of contamination of liquid medicine, inability to remove stubborn stains on medicine bottles, etc., and achieve the effect of ensuring quality and avoiding interference and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

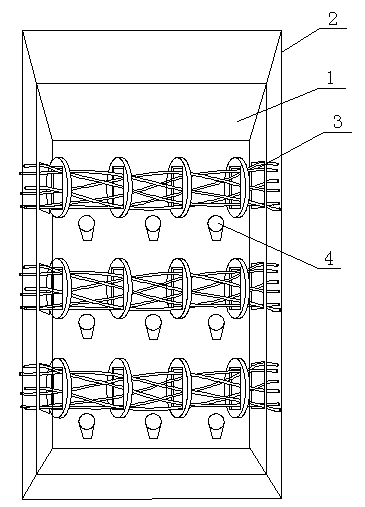

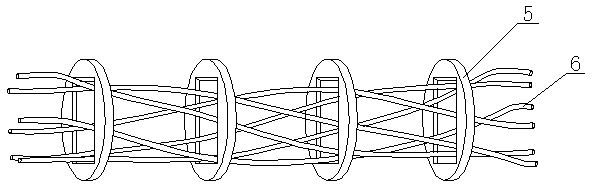

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a disinfection tank 1 and a transmission track 3 arranged on the disinfection tank 1, a glass cover 2 is arranged directly above the disinfection tank 1, and a plurality of nozzles 4 are arranged at the bottom of the disinfection tank 1, and the nozzles 4 are located on the transmission track 3, the transmission track 3 includes at least three fixed plates 5 and a plurality of twisted steel wires 6 arranged on the fixed plates 4, each fixed plate 5 is provided with a through hole in the middle, and the steel wire 6 passes through the through hole Fixed on the fixed plate 5.

[0019] As a preference, three transmission tracks 3 are provided on the disinfection tank 1 of this embodiment, and three spray heads 4 are provided directly below each transport track 3, and the distances between adjacent spray heads 4 are equal.

[0020] The conveying track 3 of this embodiment includes four fixing plates 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com