Core pulling injection mold for manufacturing multi-inclined-hole products

A technology for injection molds and products, applied in the field of core-pulling injection molds, which can solve the problems of complex structure, difficulty in processing small-sized workpieces and workpieces with multiple inclined holes, cumbersome operation, etc., achieves convenient operation, and realizes multiple core-pulling and large-angle core-pulling The effect of core operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

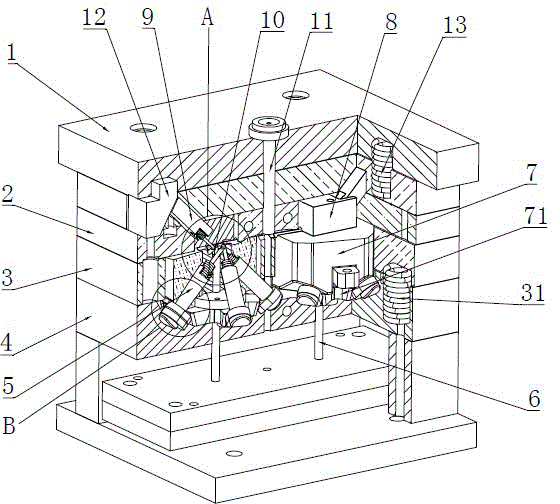

[0023] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

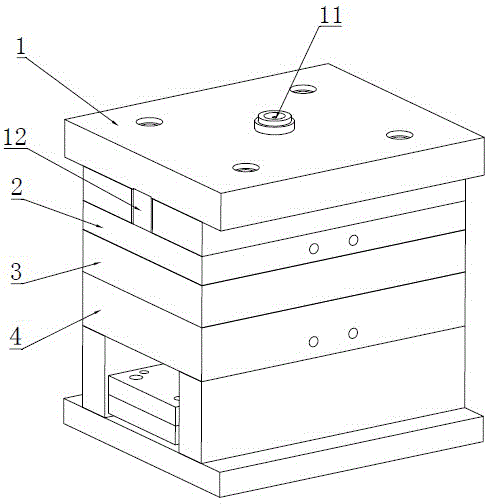

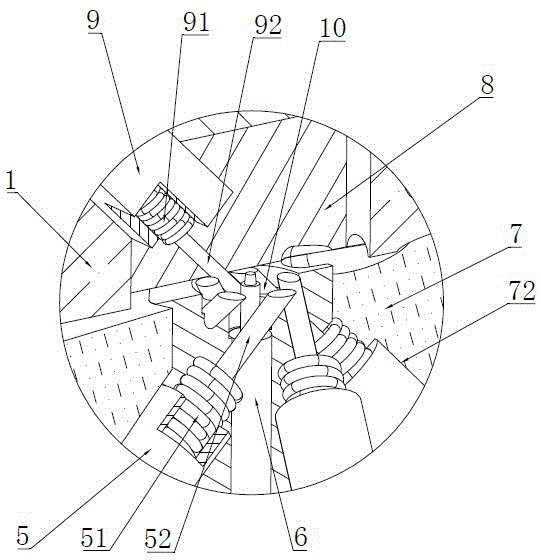

[0024] As shown in the figure, the core-pulling injection mold for producing multi-slanted hole products is mainly used for the production of auto parts and speaker parts, including an upper plate 1, an upper parting plate 2, and a lower parting plate stacked in sequence from top to bottom. Model plate 3 and lower plate 4, described upper parting plate 2 and lower parting plate 3 are provided with a mold core, and the mold core includes an upper mold kernel 8 fixed in the lower parting plate 3 and a mold core fixed in the lower parting plate 3. The lower mold core 7 in the template 3, the upper mold core 8 and the lower mold core 7 cooperate to form a cavity 10, the cavity 10 is connected with the injection pipe 11, and the lower mold core 7 is provided with several The lower core-pulling slideway 72 runs through obliquely. The lower core-pulling slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com