Bottle cap and bottle combination structure

A bottle cap and bottle body technology, which is applied in the field of bottle cap and bottle combination structure, can solve the problems of difficult identification of bottle caps for secondary use, low yield of bottle cap structure, etc., to facilitate processing and injection molding, improve safety and reliability The effect of sex and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

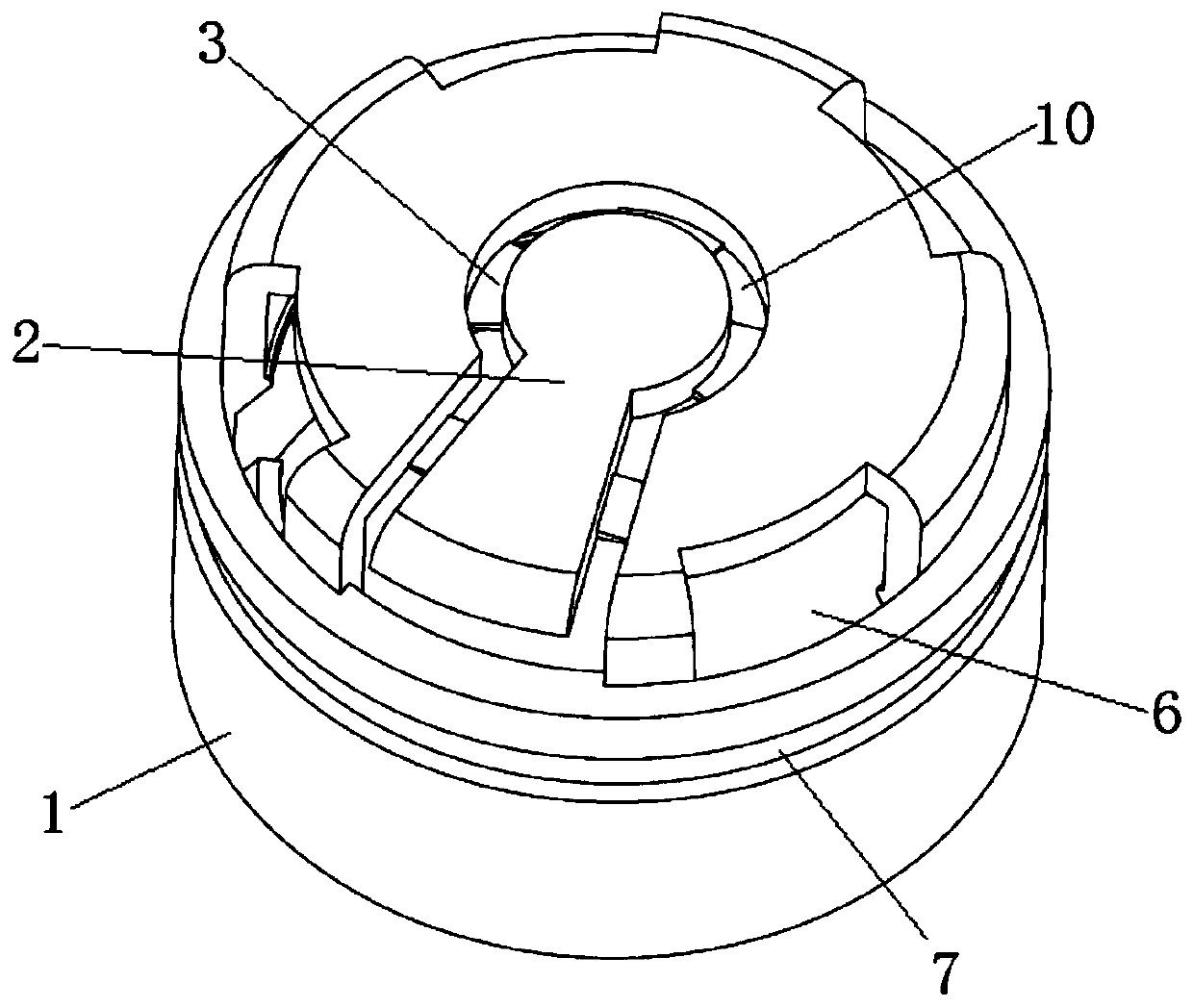

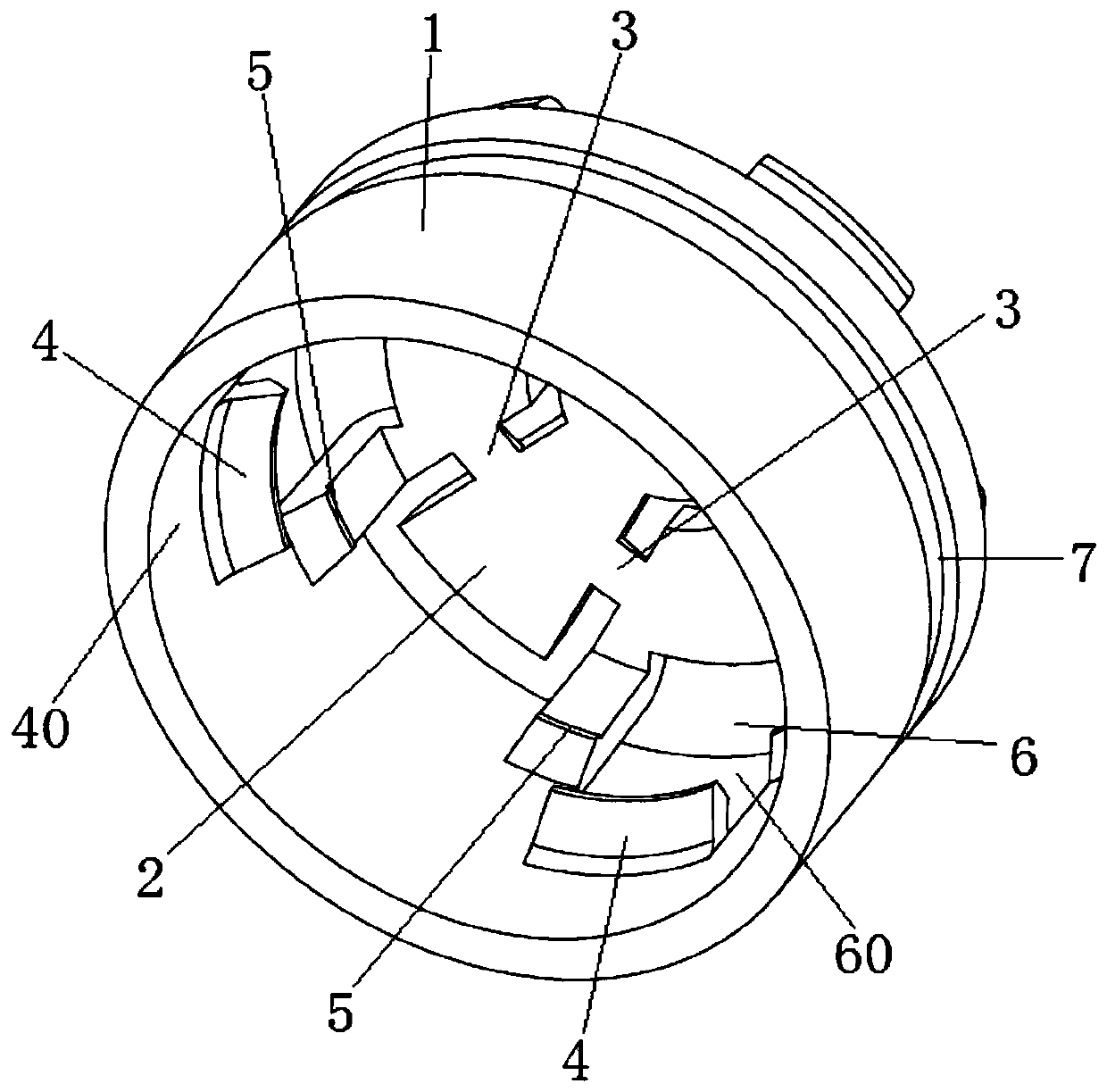

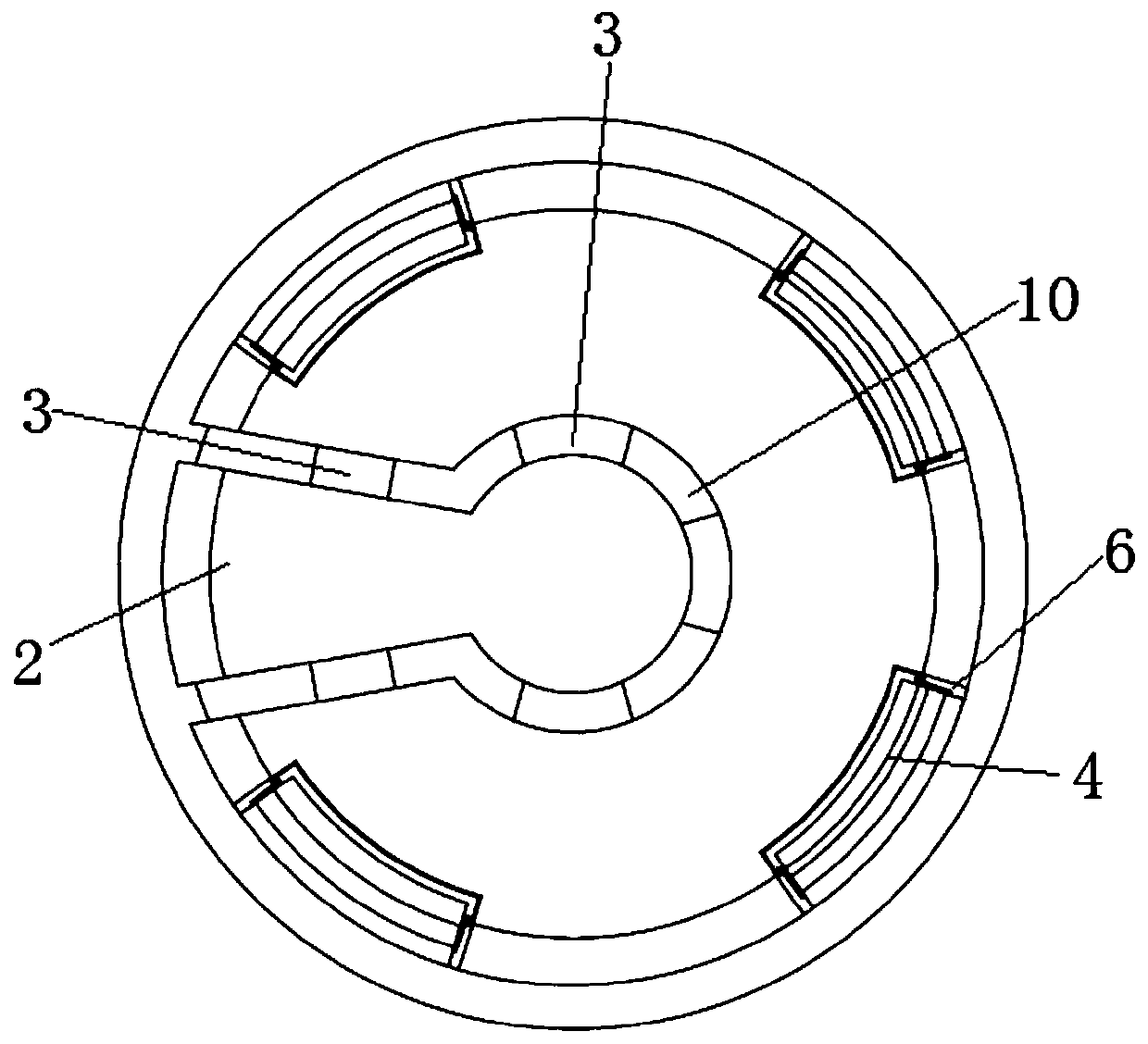

[0051] This embodiment provides a bottle cap, the bottle cap is made of plastic material, such as figure 1As shown, it includes a cover body, a pull tab 2, at least one self-destruct part, a connecting part and at least one flow structure. The top wall of the cover body 1 has a material intake 10. In this embodiment, the shape of the material intake 10 is a keyhole type, the shape of the pull tab 2 matches the shape of the material intake 10, and the thickness of the pull tab 2 is The same thickness as the top wall, meanwhile, the upper surface and the lower surface of the pull piece 2 are flush with the outer surface and the inner surface of the corresponding top wall respectively, which can prevent the pull piece 2 from protruding from the lower surface of the top wall so that the sealing body ( (not shown in the figure) exerts force on the pull tab 2, or protrudes from the upper surface of the top wall, and the pull tab 2 is squeezed by external objects during installation ...

Embodiment 2

[0065] This embodiment provides a bottle combination structure, which includes a bottle body and the bottle cap described in Embodiment 1, and the bottle cap is sleeved and fixed on the bottle mouth of the bottle body to form a package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com