Thread tension adjustment mechanism of sewing machine

A tension adjustment and sewing machine technology, which is applied to sewing machine components, tension devices, sewing equipment, etc., can solve the problems of inconvenience in assembly, easy to scratch threads, increase in manufacturing cost, etc., so as to improve the convenience of assembly and avoid vibration loosening. , The effect of saving assembly components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

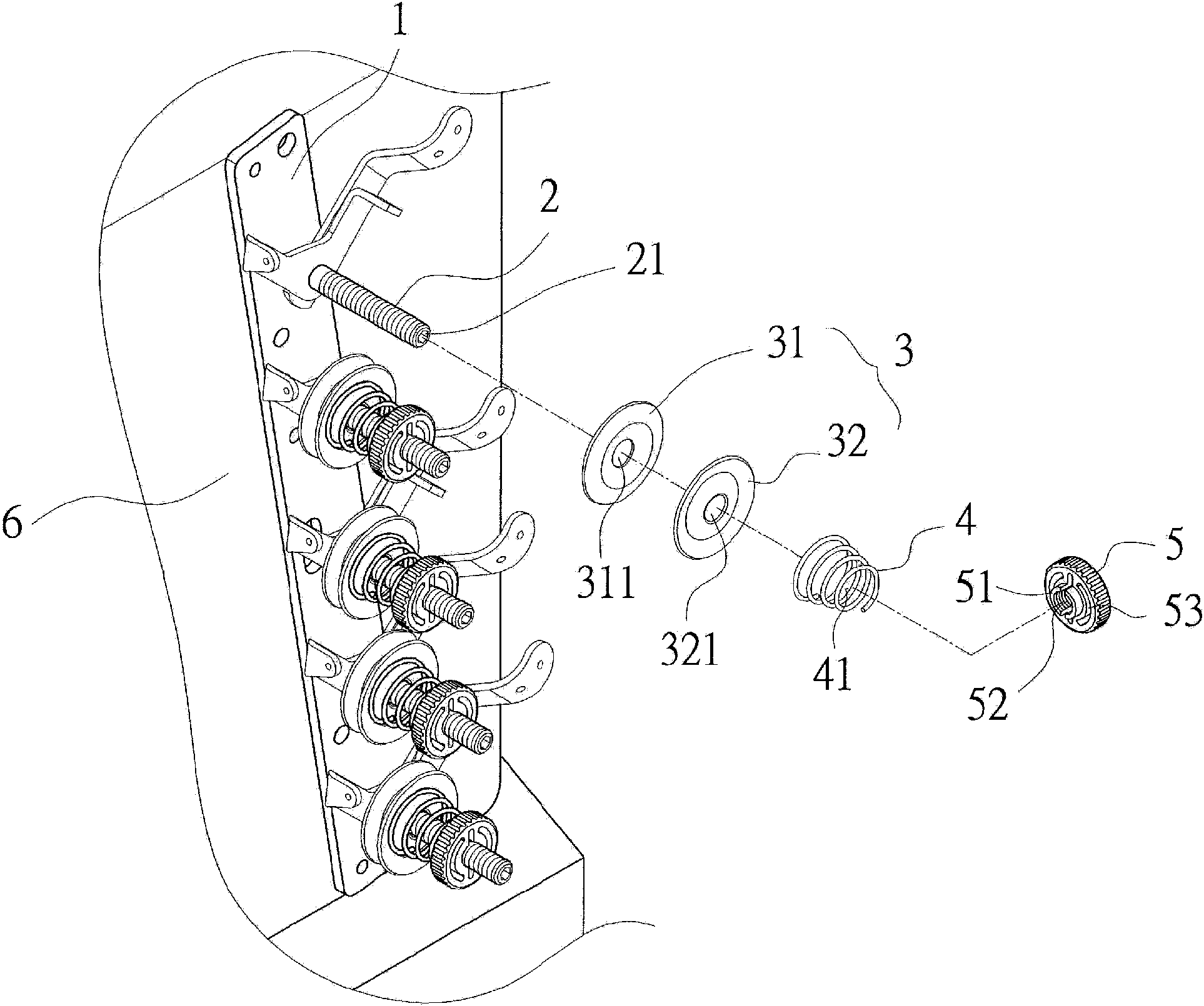

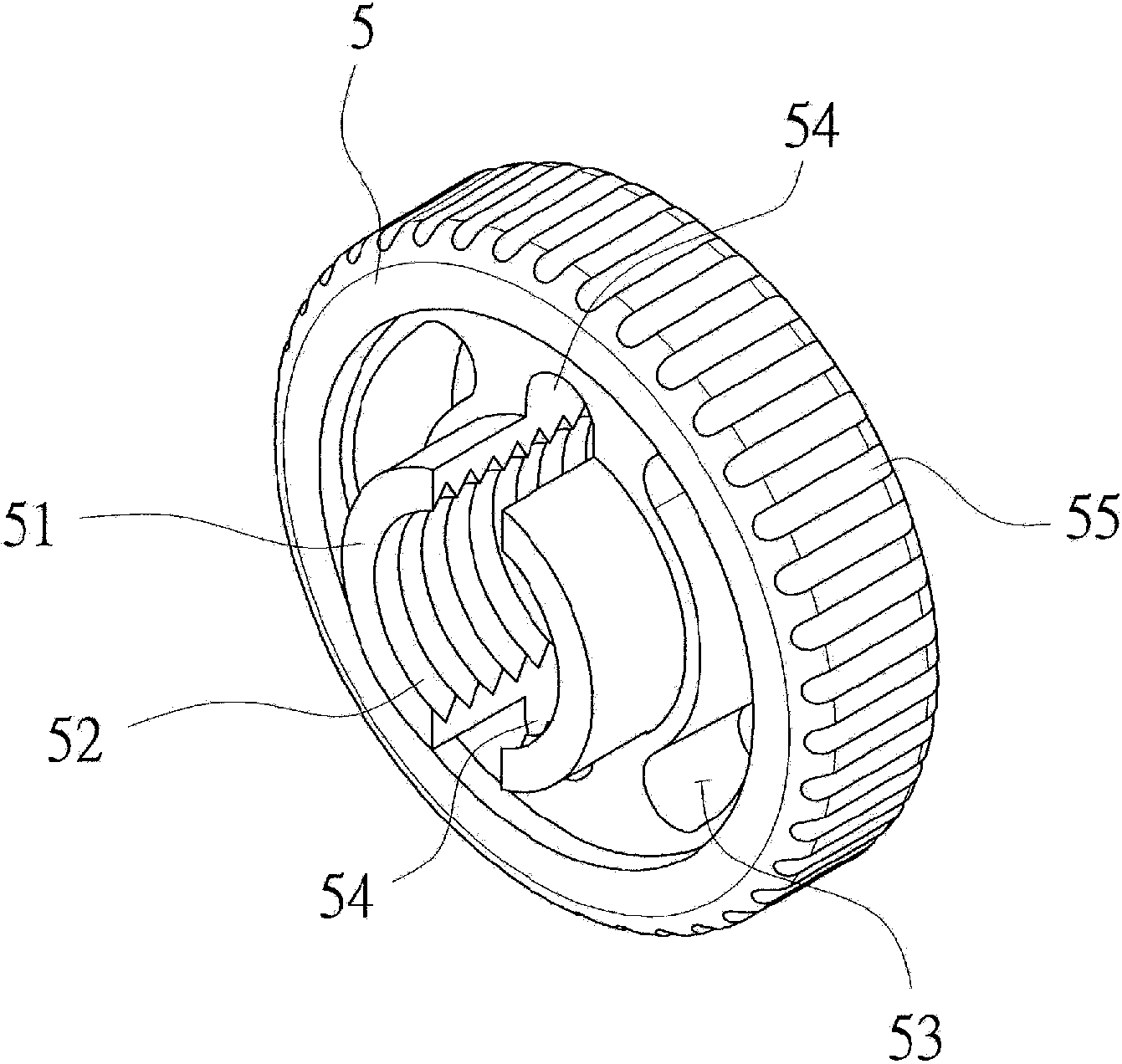

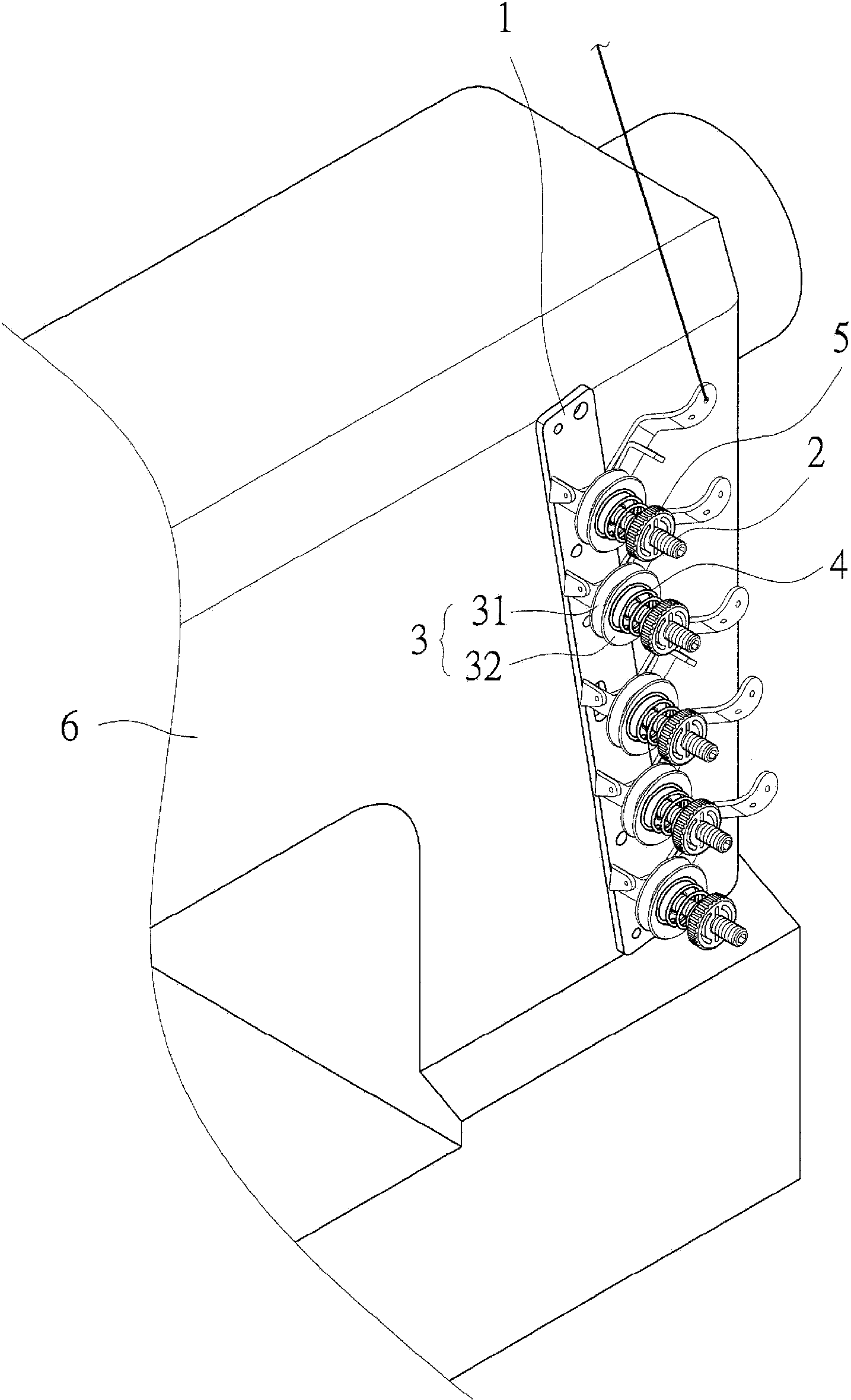

[0052] First, see figure 1 Shown is the suture tension adjustment mechanism of the sewing machine of the present invention, which is composed of a fixed plate 1, a screw rod 2, a thread tension piece 3, a spring 4 and a knob 5; wherein:

[0053] The fixing plate 1 is assembled with the body 6 of the sewing machine at an appropriate position;

[0054] The screw 2 is a solid rod body with no slots and threaded sections. A polygonal turning hole 21 is provided on the front end for the plate glove, and the other end is assembled to the screw hole of the machine body or the fixed plate 1. superior;

[0055] The clamping piece 3 includes a first clamping piece 31 and a second clamping piece 32, and the center of the first clamping piece 31 and the second clamping piece 32 are provided with through holes 311, 321 to be sleeved on the screw 2. Make the first clamping piece 31 and the second clamping piece 32 contact each other, and make the first clamping piece 31 stick to the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com