A Plug Cone Mechanism Realizing Omnidirectional Vector Adjustment of Axisymmetric Nozzle

An axisymmetric nozzle and plug cone technology, which is applied in the machine/engine, jet propulsion and other directions, can solve the problems of low infrared stealth ability, heavy weight, and many moving components of the axisymmetric vector nozzle, and achieve the realization of omnidirectional vector Adjustment, reduction in outline size, and the effect of fewer moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

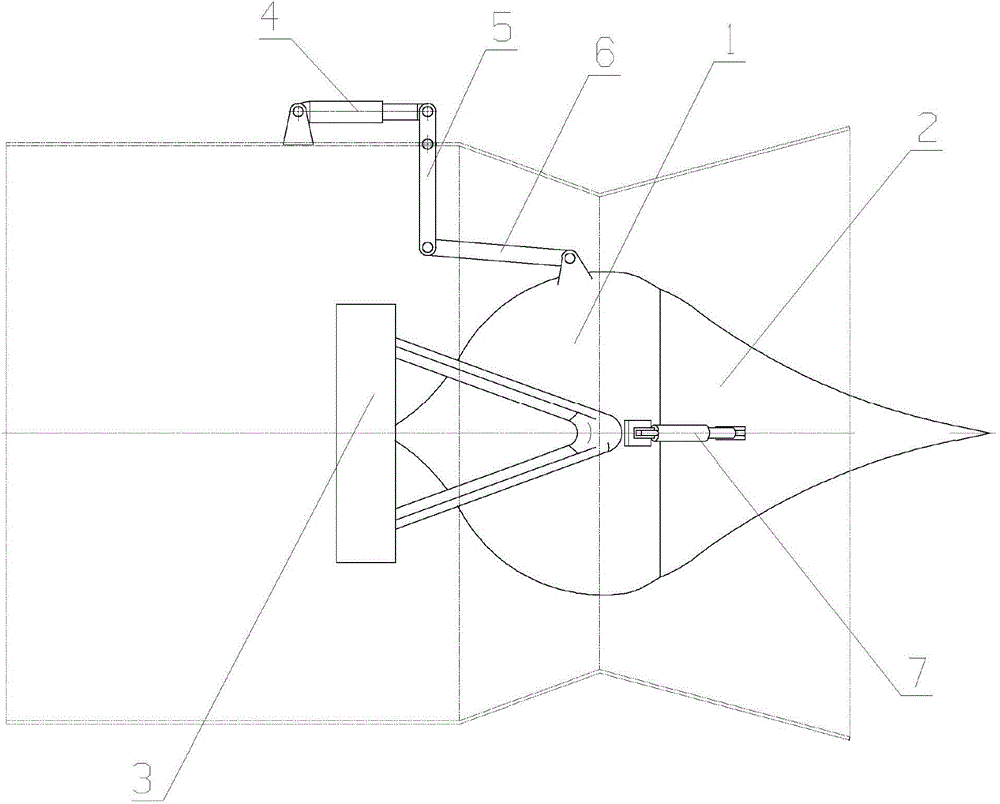

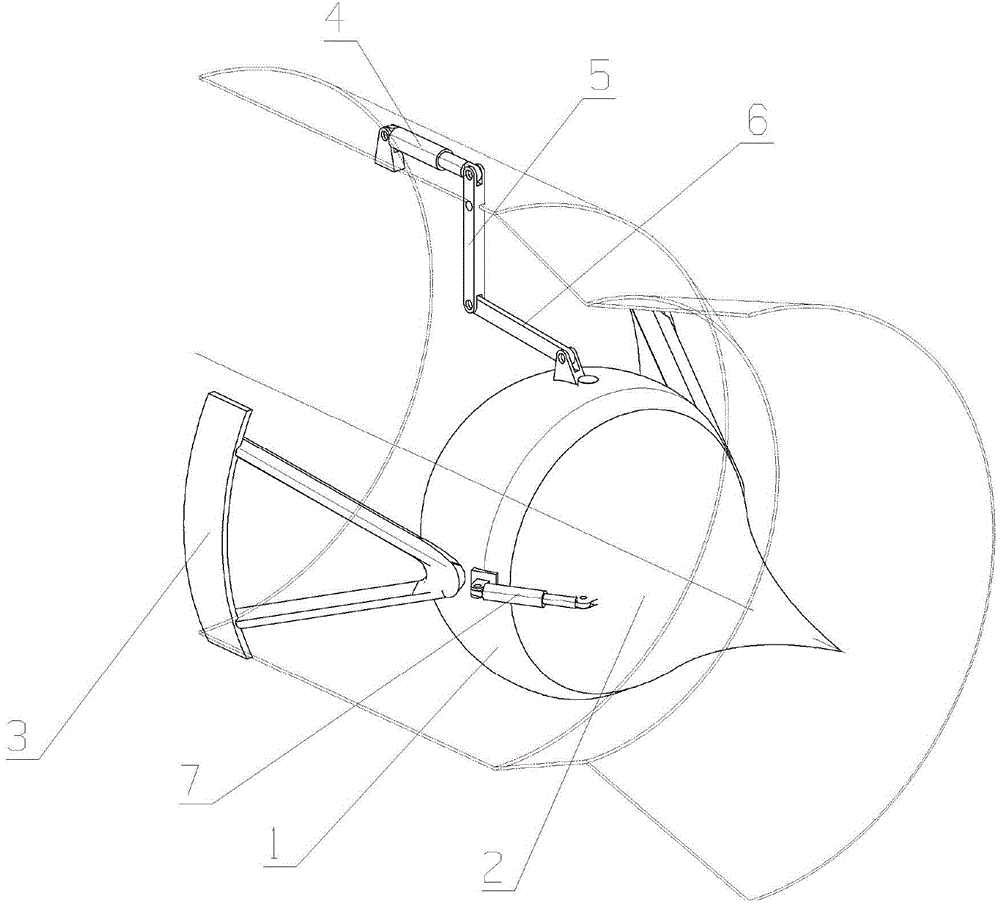

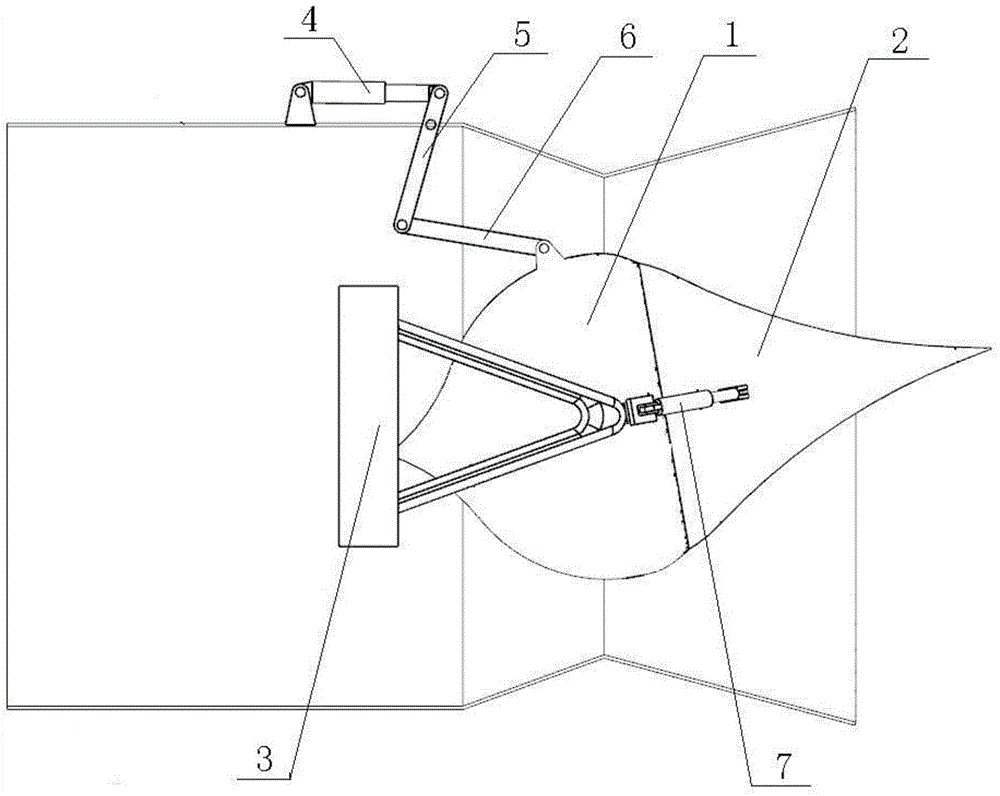

[0025] This embodiment provides a plug cone mechanism for realizing the omnidirectional vector adjustment of the axisymmetric nozzle, which is characterized in that: the plug cone mechanism for realizing the omnidirectional vector adjustment of the axisymmetric nozzle includes Rear section 2, support frame 3, first actuator 4, rotating rod 5, connecting rod 6 and second actuator 7;

[0026] Among them: the front section 1 of the plug cone and the rear section 2 of the plug cone form a central cone structure, the contact position of the front section 1 of the plug cone and the rear section 2 of the plug cone is a concentric spherical surface, and the two are connected by a rotating pair perpendicular to the axis of the nozzle , and connect the concentric spherical surface of the rotating pair passing through the front section 1 of the plug cone and the rear section 2 of the plug cone, which is used to realize the vector adjustment of the gas flow of the nozzle, and at the same t...

Embodiment 2

[0039] This embodiment provides a plug cone mechanism for realizing the omnidirectional vector adjustment of the axisymmetric nozzle, which is characterized in that: the plug cone mechanism for realizing the omnidirectional vector adjustment of the axisymmetric nozzle includes Rear section 2, support frame 3, first actuator 4, rotating rod 5, connecting rod 6 and second actuator 7;

[0040] Among them: the front section 1 of the plug cone and the rear section 2 of the plug cone form a central cone structure, the contact position of the front section 1 of the plug cone and the rear section 2 of the plug cone is a concentric spherical surface, and the two are connected by a rotating pair perpendicular to the axis of the nozzle , and connect the concentric spherical surface of the rotating pair passing through the front section 1 of the plug cone and the rear section 2 of the plug cone, which is used to realize the vector adjustment of the gas flow of the nozzle, and at the same t...

Embodiment 3

[0050] This embodiment provides a plug cone mechanism for realizing the omnidirectional vector adjustment of the axisymmetric nozzle, which is characterized in that: the plug cone mechanism for realizing the omnidirectional vector adjustment of the axisymmetric nozzle includes Rear section 2, support frame 3, first actuator 4, rotating rod 5, connecting rod 6 and second actuator 7;

[0051] Among them: the front section 1 of the plug cone and the rear section 2 of the plug cone form a central cone structure, the contact position of the front section 1 of the plug cone and the rear section 2 of the plug cone is a concentric spherical surface, and the two are connected by a rotating pair perpendicular to the axis of the nozzle , and connect the concentric spherical surface of the rotating pair passing through the front section 1 of the plug cone and the rear section 2 of the plug cone, which is used to realize the vector adjustment of the gas flow of the nozzle, and at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com