The electromagnetic valve

A solenoid valve and armature technology, applied in the field of solenoid valves, can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

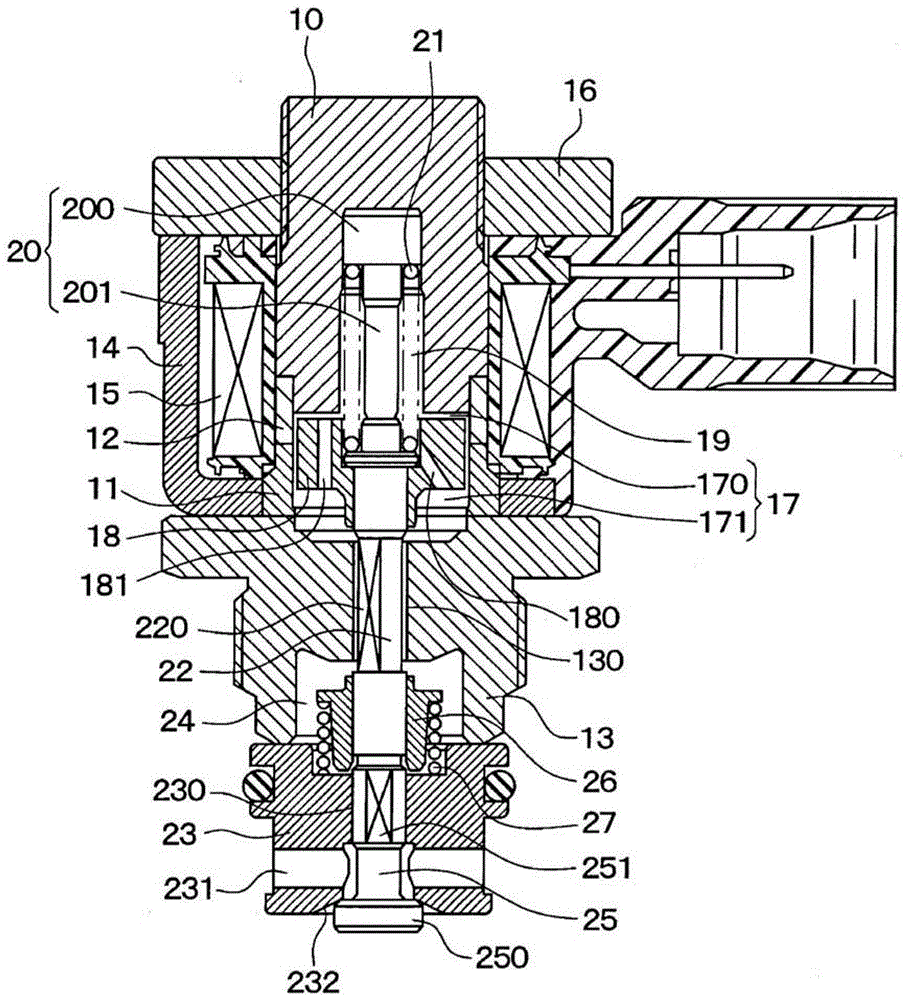

[0021] The solenoid valve of the present embodiment is used as a suction metering valve of a fuel injection device (also referred to as a fuel injection system). The fuel injection device supplies fuel to, for example, an internal combustion engine, more specifically a diesel engine. The fuel injection equipment has a pump and a (high pressure) common rail. The pump compresses fuel to high pressure and discharges the pressurized fuel toward the common rail. The common rail accumulates fuel under pressure. A suction metering valve regulates the flow of fuel supplied to the pump.

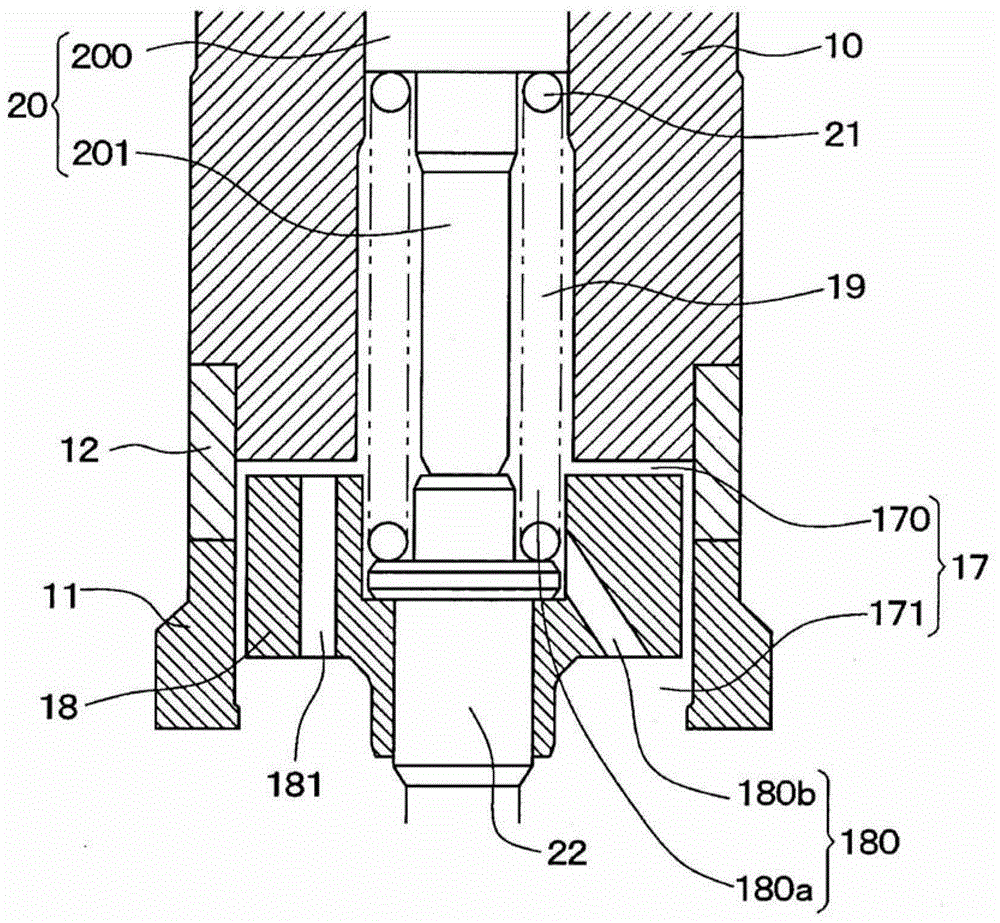

[0022] refer to figure 1 and figure 2 , the stator core 10 is configured as a cup-shaped body and made of a magnetic metal material, and the sleeve 11 is configured as a cylindrical tubular body and made of a magnetic metal material. The stator core 10 and the sleeve 11 are integrated together by a collar 12 configured in a cylindrical tubular form and made of a non-magnetic metal material. Spe...

no. 2 example )

[0052] A second embodiment of the present invention will be described. In the present embodiment, the structure of the armature 18 is changed, and the rest of the solenoid valve is the same as that of the first embodiment. Therefore, in the following discussion, only the different parts of the solenoid valve from the first embodiment will be described.

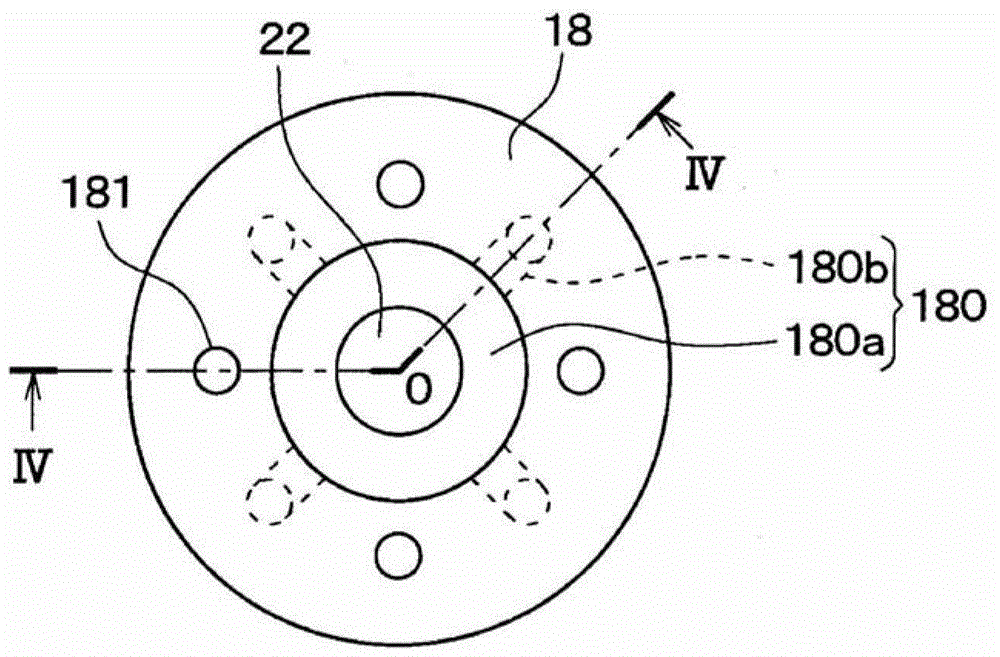

[0053] like Figure 5 and Image 6 As shown, in the surface area of the armature 18 , the connection groove 28 extends from each second communication channel 181 towards the radial center of the armature 18 opposite the stator core 10 .

[0054] Because each second communication channel 181 is provided with the connection groove 28, the movement of the liquid between the second communication channel 181 and the first spring chamber 19 becomes easy, ie, improved. Therefore, generation of cavitation in the first armature chamber 170 and the first spring chamber 19 when the armature 18 is moved in a direction away from the s...

no. 3 example )

[0056] A third embodiment of the present invention will be described. In the current embodiment, the plate 29 is added, and the rest of the structure of the solenoid valve is basically the same as that of the first embodiment. Therefore, in the following discussion, only the different parts of the solenoid valve from the first embodiment will be described.

[0057] like Figure 7 As shown, a plate 29 configured in a cylindrical tubular form (also referred to as an annular form) is set as an opposing member (also referred to as an armature side opposing member or as an opposing member) in a second armature chamber 171. simply referred to as opposing components). The plate 29 is fixed to the guide 13 by, for example, press fitting.

[0058] Furthermore, one end surface of the plate 29 is axially opposed to a corresponding surface portion of the armature 18 arranged on the axial side where the second armature chamber 171 is located. The size of the gap (ie, the distance) betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com