Riveting nut

A technology for riveting nuts and nut bodies, applied in the directions of nuts, connecting members, threaded fasteners, etc., can solve problems such as the inability to fix the nut body and the falling off of the card body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

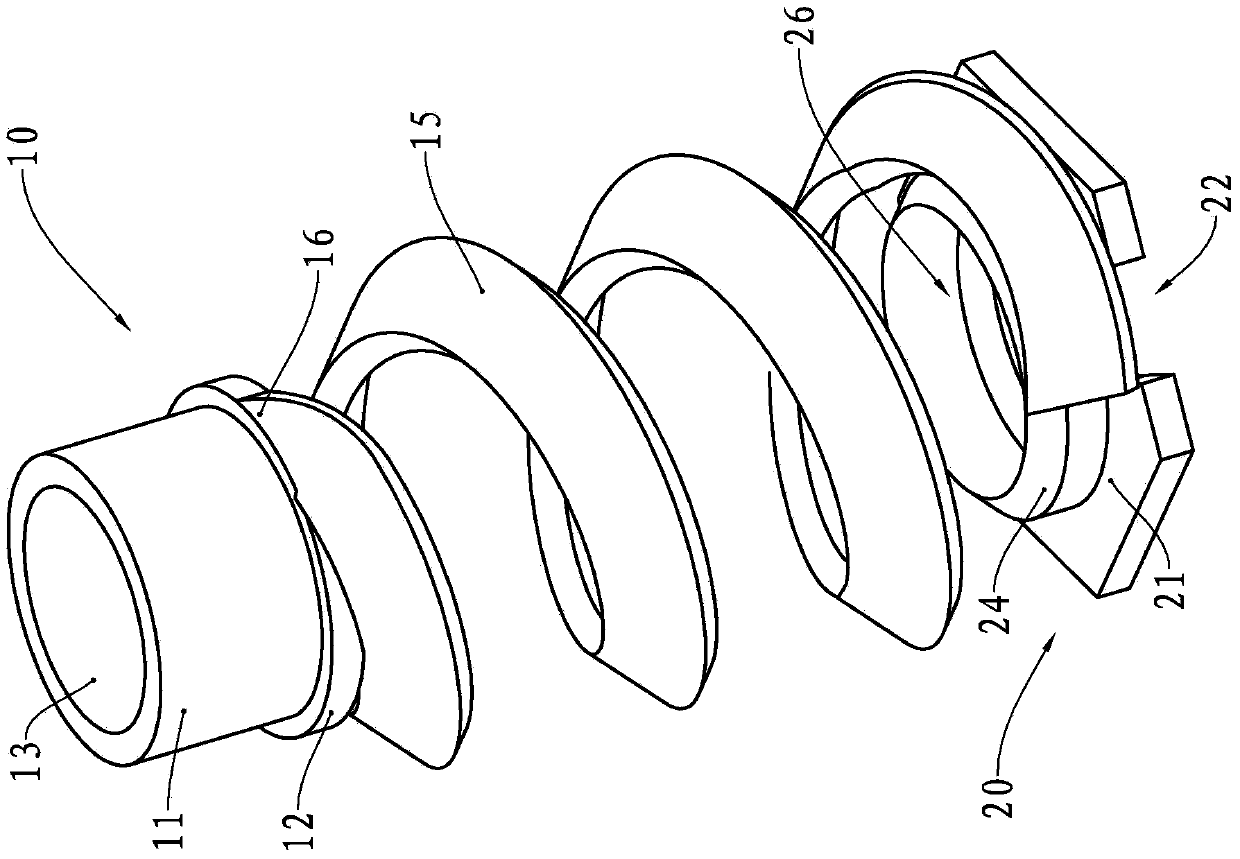

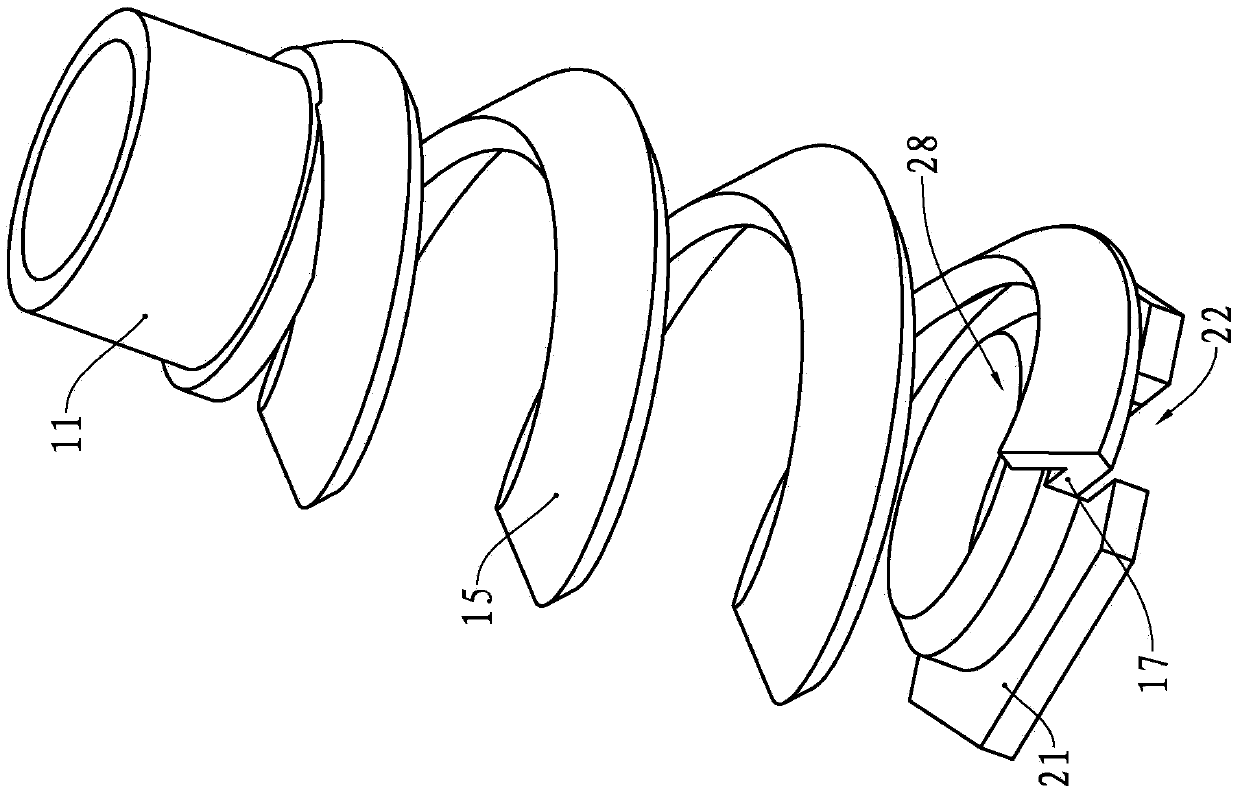

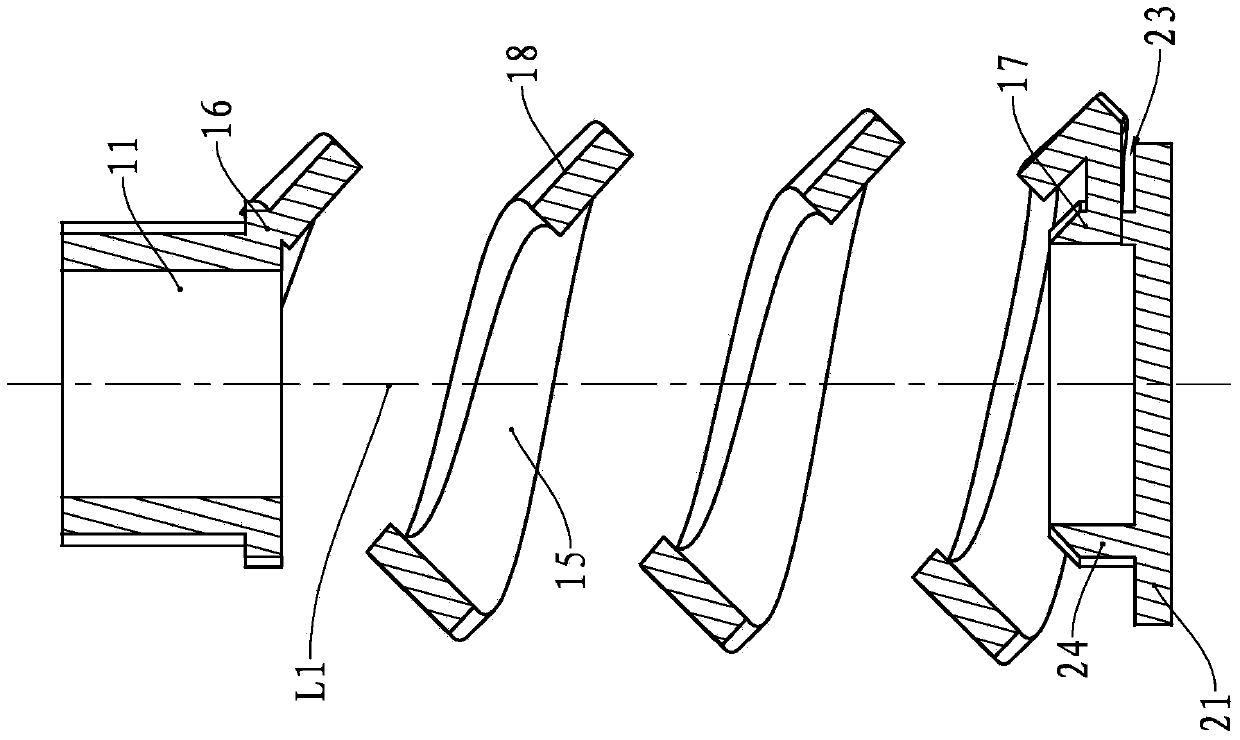

[0032] see figure 1 and figure 2 , The riveting nut 10 of the present embodiment has a circular cylindrical nut body 11, a ring flange 12 is provided at the lower end of the nut body 11, a through hole 13 is formed in the middle part of the nut body 11, and internal threads are provided on the inner wall of the nut body 11 ( figure 1 and figure 2 not shown). When the bolt is screwed into the nut body 11 , the external thread on the bolt cooperates with the internal thread of the nut body 11 , and as the bolt rotates, relative displacement will occur between the bolt and the nut body 11 .

[0033] The lower end of the nut body 11 is provided with a helical connecting portion 15, the first end 16 of the connecting portion 15 is fixedly connected with the flange 12 of the nut body 11, and the connecting portion 15 is formed from the flange 12 of the nut body 11 along the edge of the nut body 11. Axial helical extension.

[0034] The lower end of the connecting portion 15 i...

no. 2 example

[0047] see Figure 8 , The riveting nut 40 of this embodiment has an annular columnar nut body 41 , and a flange 42 is provided at the lower end of the nut body 41 . The middle part of the nut body 41 is provided with a through hole 43, and the inner wall of the nut body 41 is provided with an internal thread ( Figure 8 not shown).

[0048] The connecting portion 45 is located below the nut body 41 , and the first end 46 of the connecting portion 45 is fixed on the outer wall of the flange 42 . Below the connecting portion 45 is a fixing portion 50, which includes a regular hexagonal columnar fixing plate 51 and a positioning ring 55 located on the end surface of the fixing plate 51 close to the nut body 41, the positioning ring 55 is in the shape of a circular column. Moreover, a notch 52 is also provided on the fixing plate 51 . The middle part of the fixing part 50 is provided with a through hole, which passes through the fixing plate 51 and the positioning ring 55 , so...

no. 3 example

[0053] see Figure 9 The riveting nut 60 of this embodiment has a nut body 61 and a fixing portion 70 located below the nut body 61 , and the nut body 61 and the fixing portion 70 are connected by a connecting portion 65 . The nut body 61 is in the shape of a ring column, and a through hole 63 is provided in the middle thereof, and an internal thread ( Figure 9 not shown).

[0054] The connecting portion 65 is helical, and its first end 66 is fixed on the outer wall of the nut body 61 and fixed on an end of the nut body 61 away from the fixing portion 70 . The connecting portion 65 extends from the outer wall of the nut body 61 along the axial direction of the nut body 61 .

[0055] The fixing part 70 has a regular hexagonal columnar fixing plate 71 and a positioning ring 75 located on the end surface of the fixing plate 71 close to the nut body 61 , and a notch 72 is provided on the fixing plate 71 . The positioning ring 75 is circular and cylindrical, and the second end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com