Vehcile headlamp with both low-beam and high-beam and devoid of moving parts

A headlight, low beam technology, applied in the direction of headlights, light sources, electric light sources, etc., can solve problems such as easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

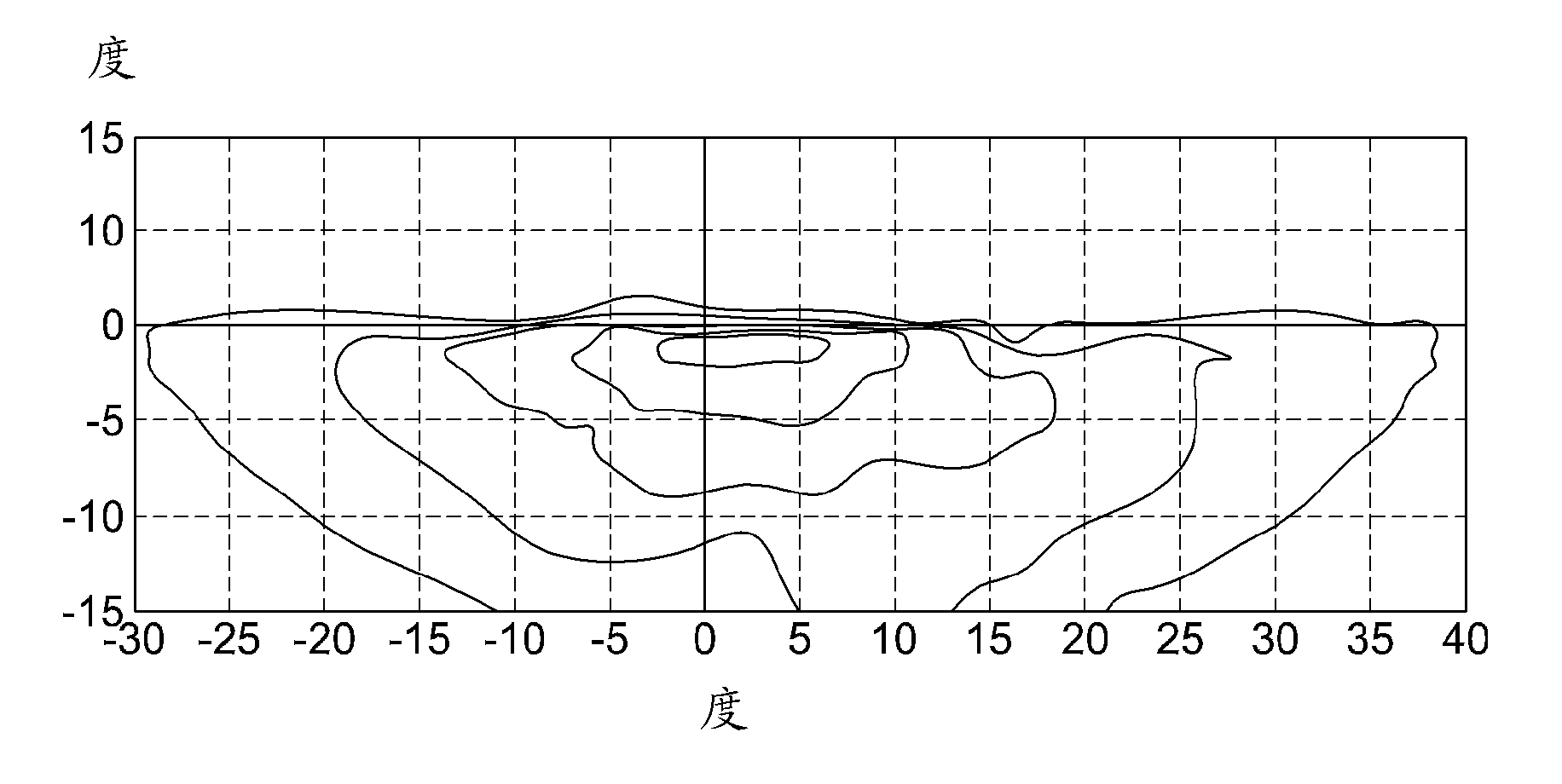

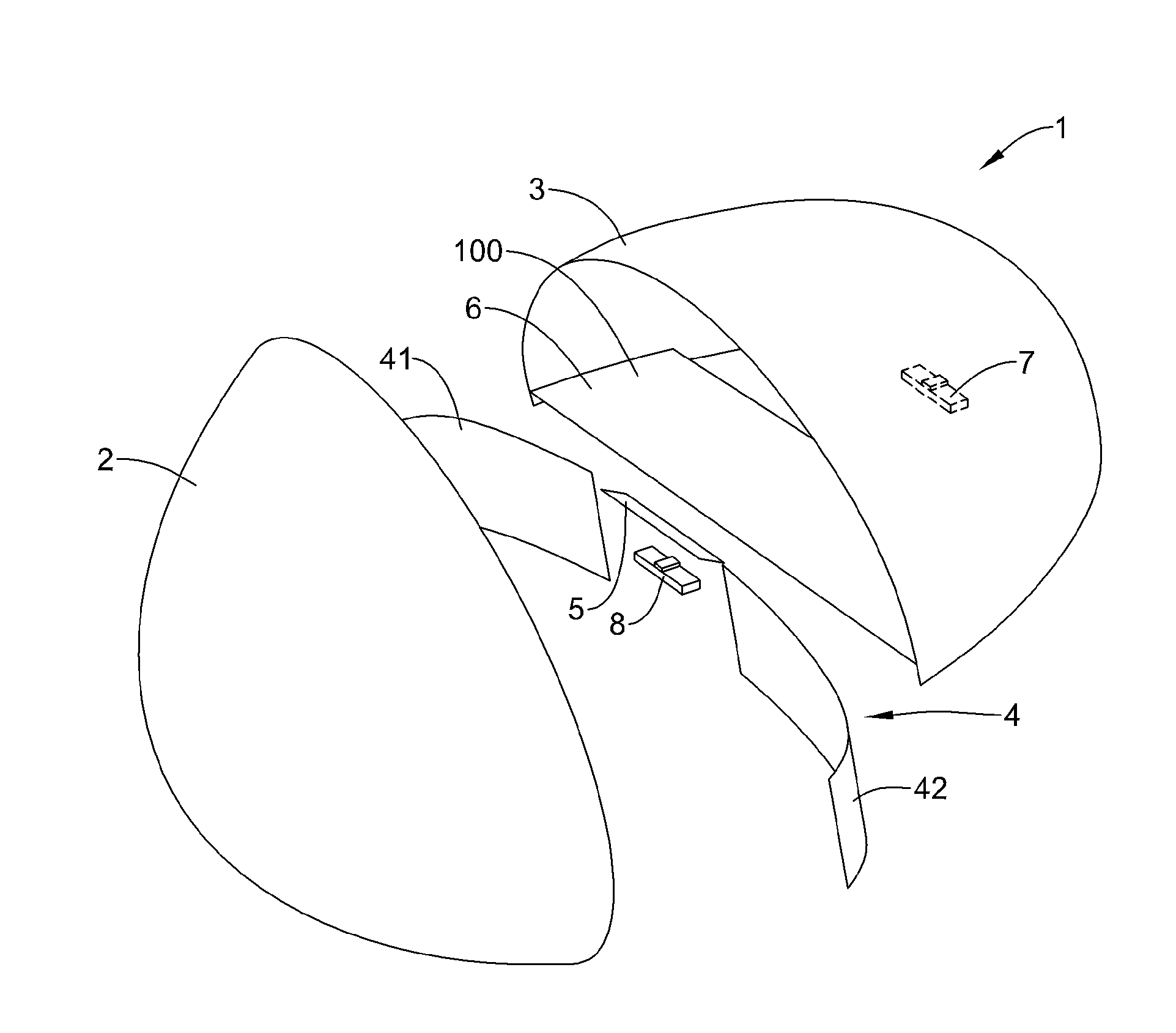

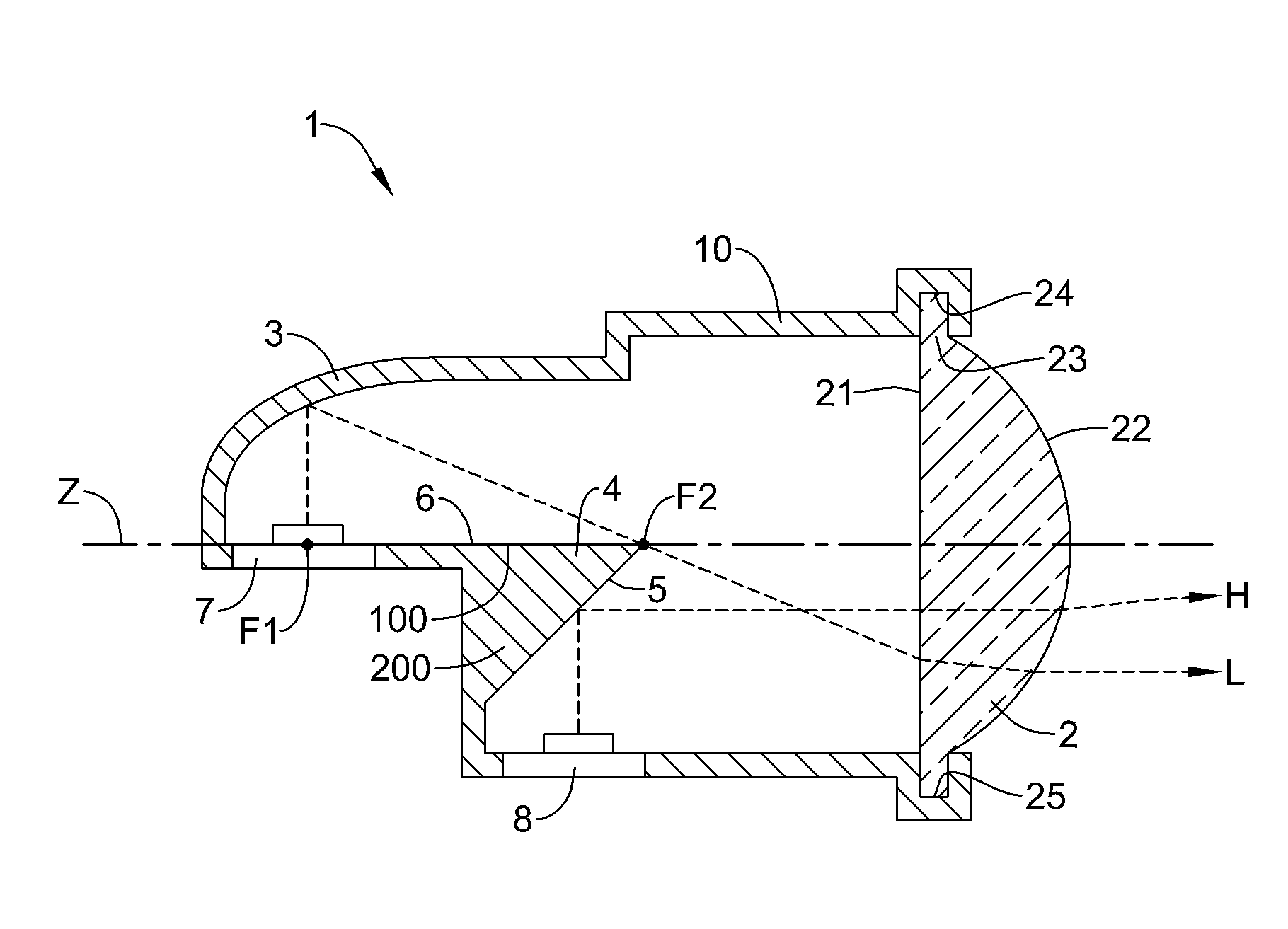

[0019] As used herein, the directional terms "upper", "lower", "top", "bottom", "side", "transverse", "longitudinal", etc. are used to describe the absolute and relative orientation of particular elements. For these descriptions it is assumed that the light exits through the "front" of the headlight, with the spatial distribution centered around a longitudinal axis generally perpendicular to the front of the headlight and the light generally parallel to the ground. These descriptions include small angle deviations from orthogonality to allow for glare reduction for oncoming traffic. It will be appreciated that while such descriptions provide orientations that would occur in typical use, other orientations are indeed possible. As used herein, the descriptive terms indicated still apply if the headlights are pointed upwards, downwards, horizontally, or in any other suitable orientation.

[0020] Automotive headlights produce both low and high beam output and do so without any m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com