Method for detecting capacity of storage battery

A detection method and battery capacity technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of high labor costs, inaccurate detection results, high maintenance costs, etc., achieve efficient performance detection, shorten cumbersome processes, reduce The effect of the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0021] The detection method of the storage battery capacity of the present invention changes the existing manual physical detection operation into informationized automatic analysis. Through the analysis and automatic comparison of the real-time discharge of the battery, real-time, accurate and efficient battery performance detection is realized.

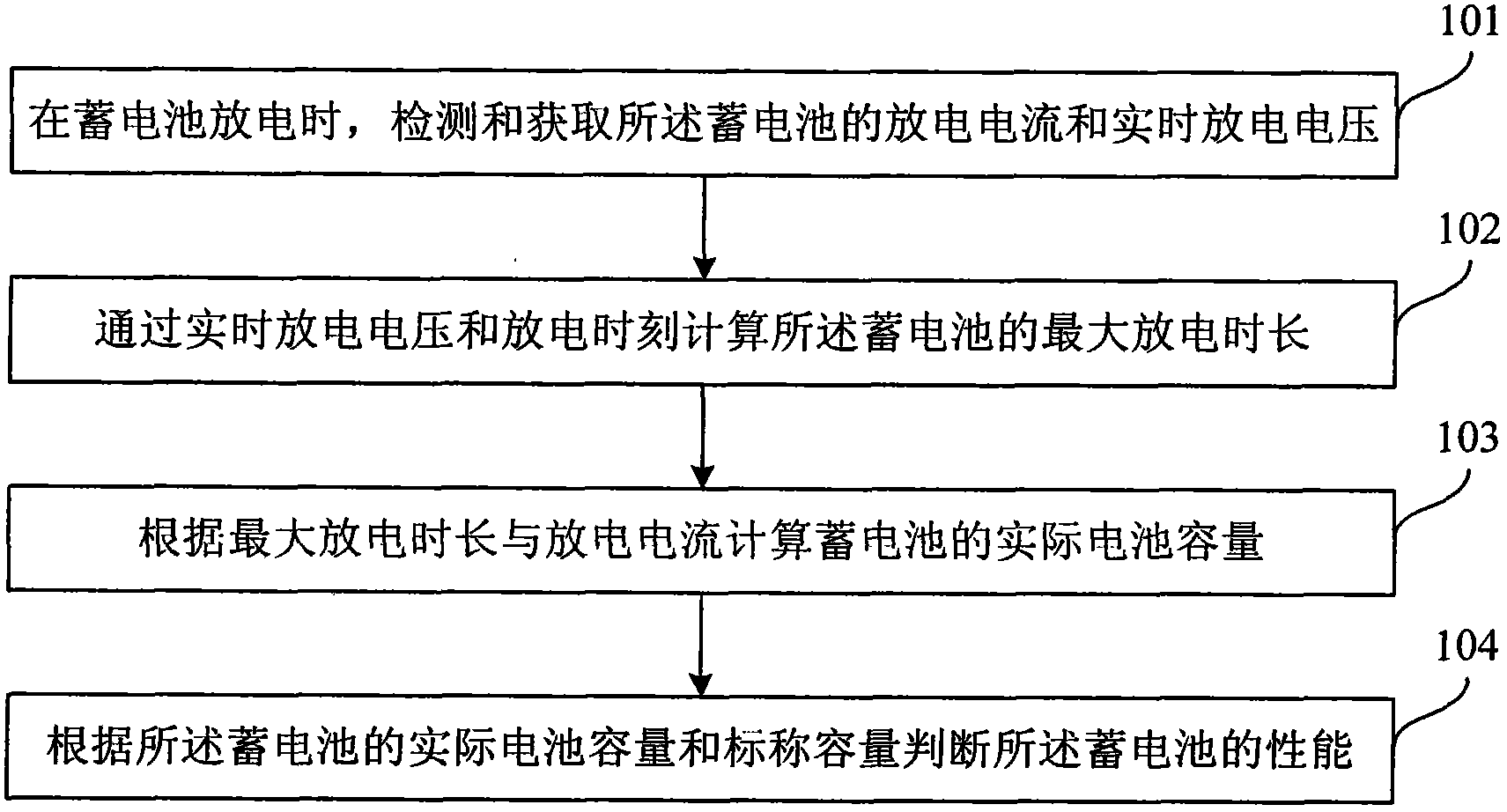

[0022] figure 1 It is a flow chart of the detection method of battery capacity of the present invention, as shown in the figure, the present invention specifically comprises the following steps:

[0023] Step 101, when the storage battery is discharging, detect and acquire the discharge current and real-time discharge voltage of the storage battery;

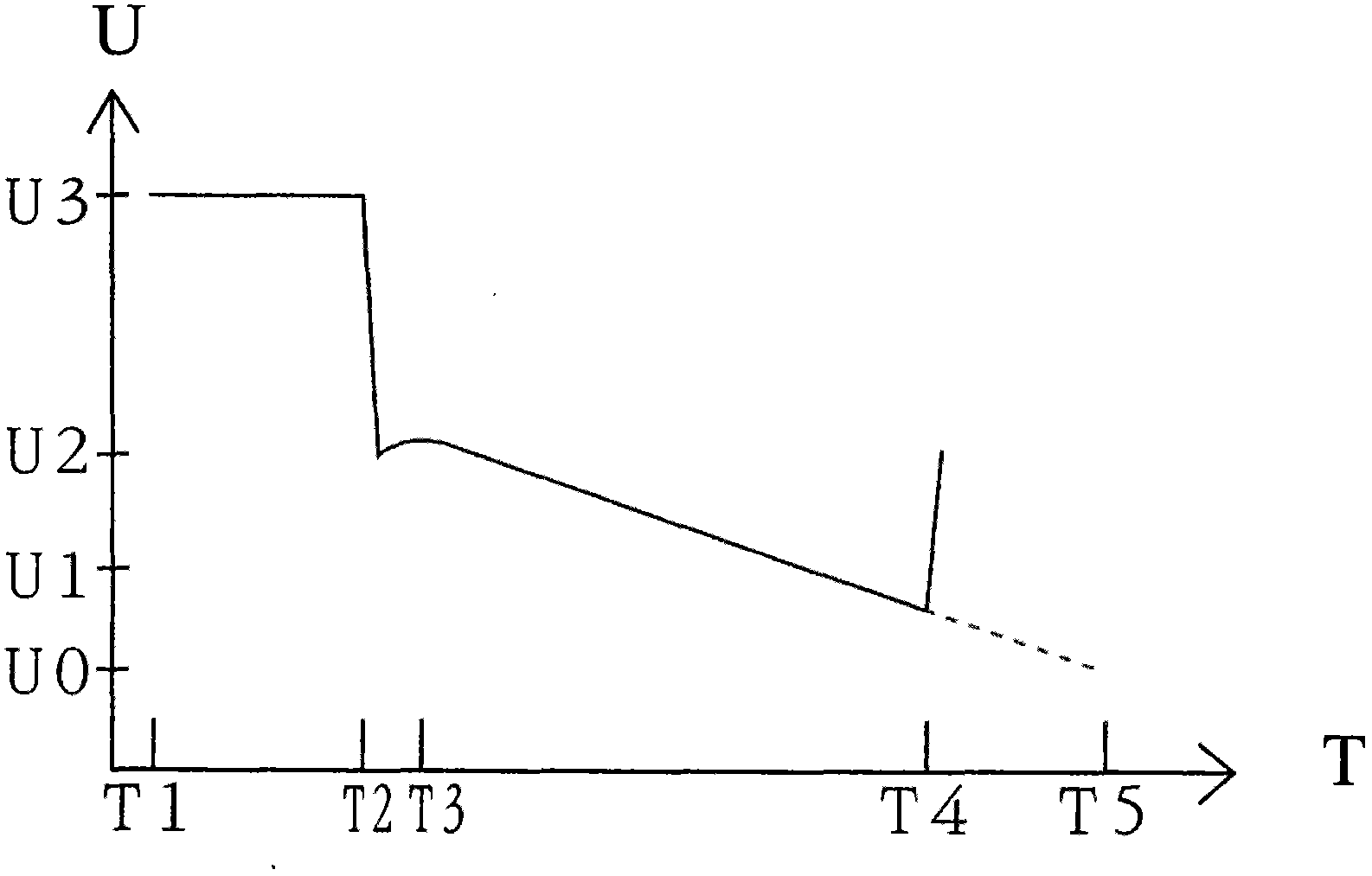

[0024] The detection of the battery is real-time, and the real-time voltage, real-time current and other parameters of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com