Hydraulic buffer system and assembly method

A hydraulic buffer and hydraulic cylinder technology, applied in the direction of liquid shock absorbers, springs, shock absorbers, etc., can solve problems such as large damping steps, vehicle vibration, poor installation, etc., to avoid stuck phenomenon, improve work efficiency, Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention.

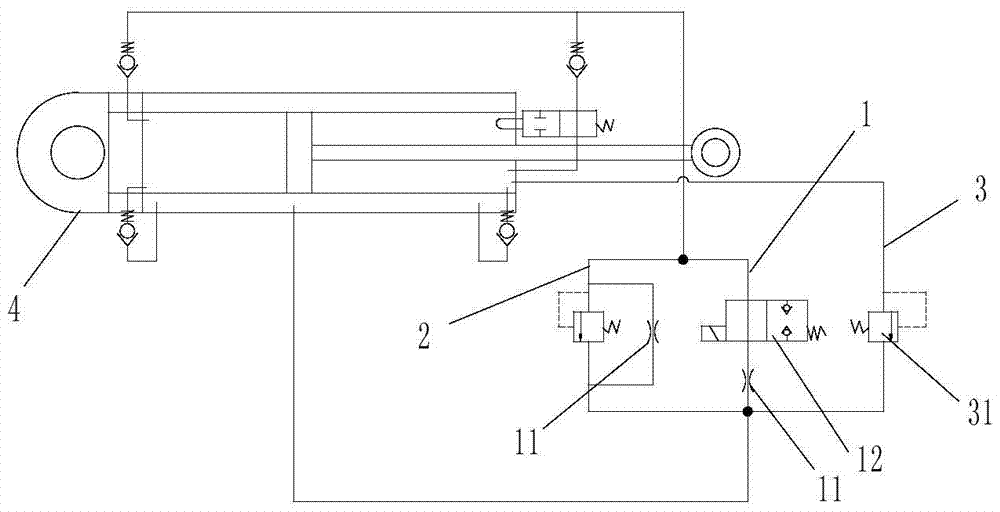

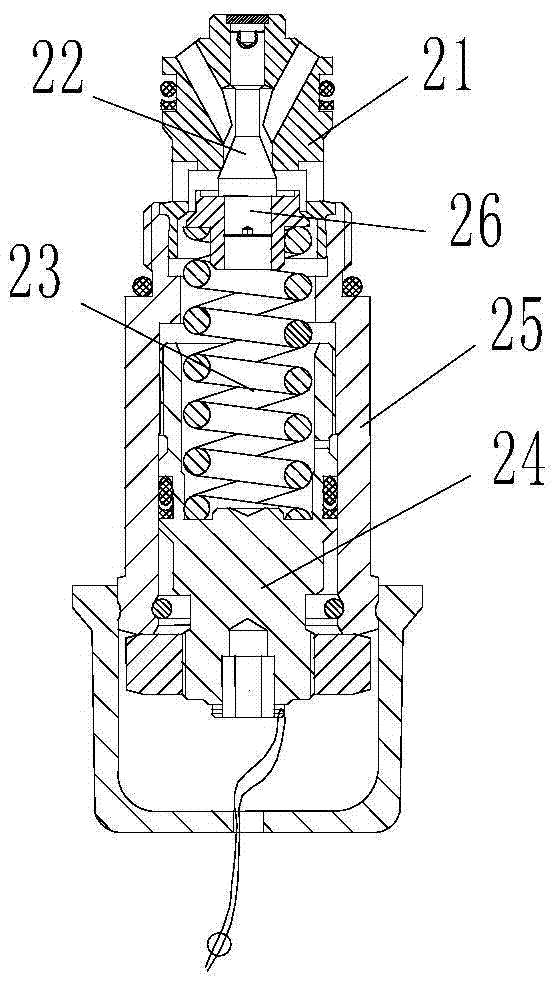

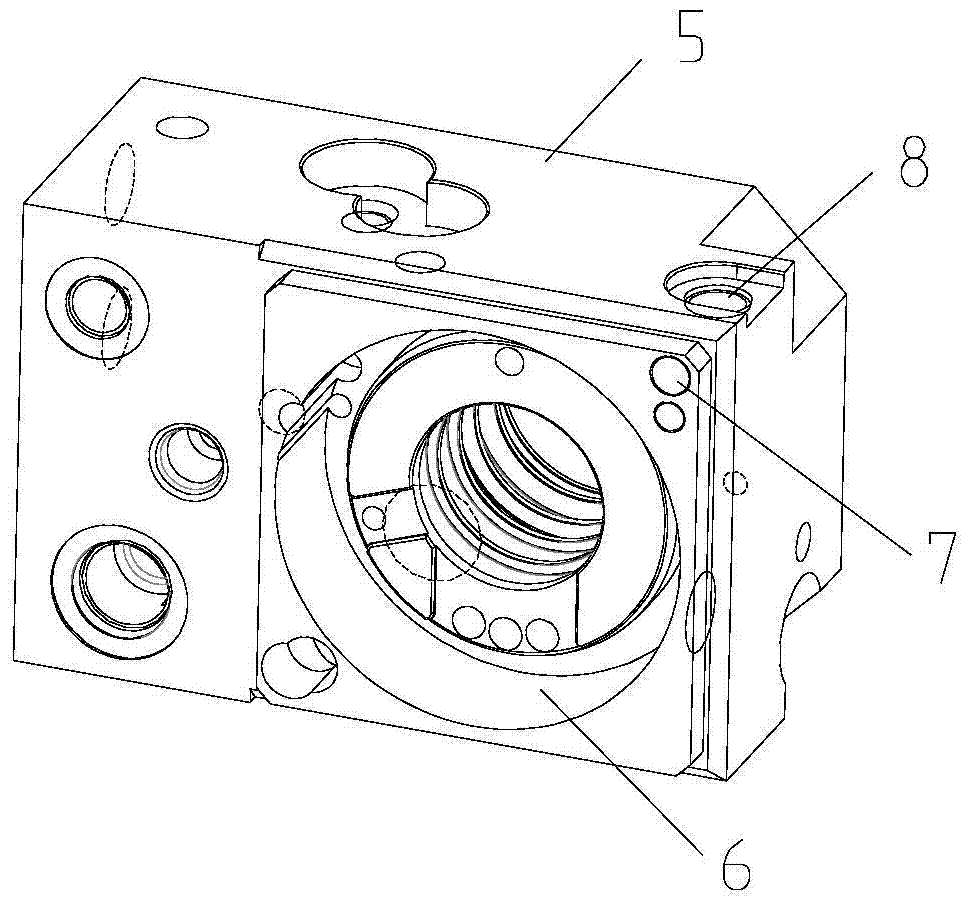

[0025] A hydraulic buffer system for articulated vehicles, see figure 1 , including a hydraulic cylinder composed of a cylinder body 4 and a piston assembly, the expansion and contraction of the piston assembly can be driven by a pressure control oil circuit, a shock absorber is installed on the hydraulic cylinder, and the pressure control oil circuit includes a primary damping system 1 , a secondary damping system 2 and a tertiary damping system 3, the primary damping system 1 and the secondary damping system 2 are connected in parallel, and the secondary damping system 2 is provided with a pressure relief device capable of releasing the low pressure The low pressure at this time means that the hydraulic pressure generated by the oil circuit is less than the opening pressure value of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com