Clapper-type electromagnetic relay

An electromagnetic relay and snap-fit technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of burning relays, equipment short-circuits, ablation and falling of metal contact materials, etc., to increase the creepage distance, The effect of avoiding electrical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

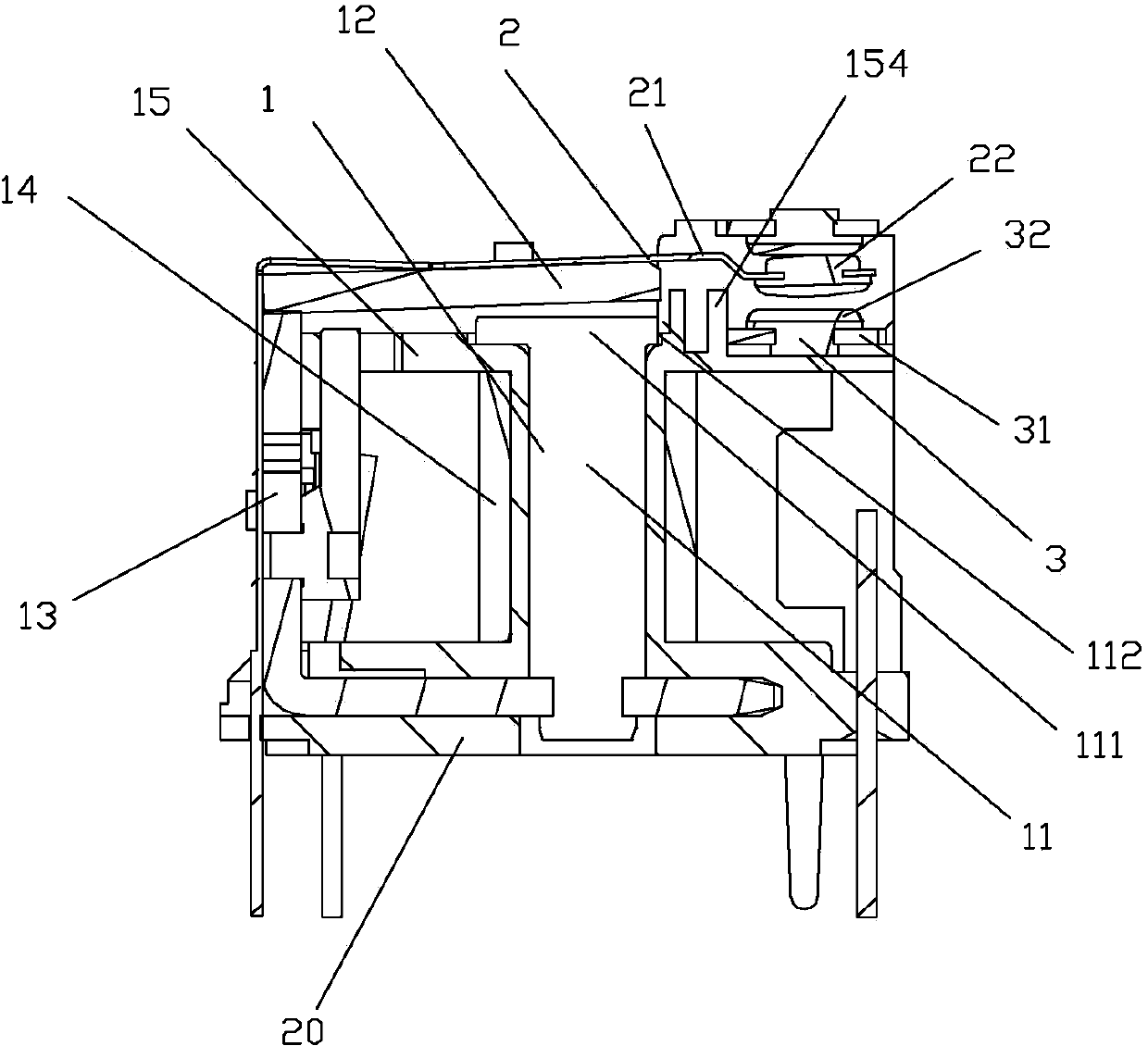

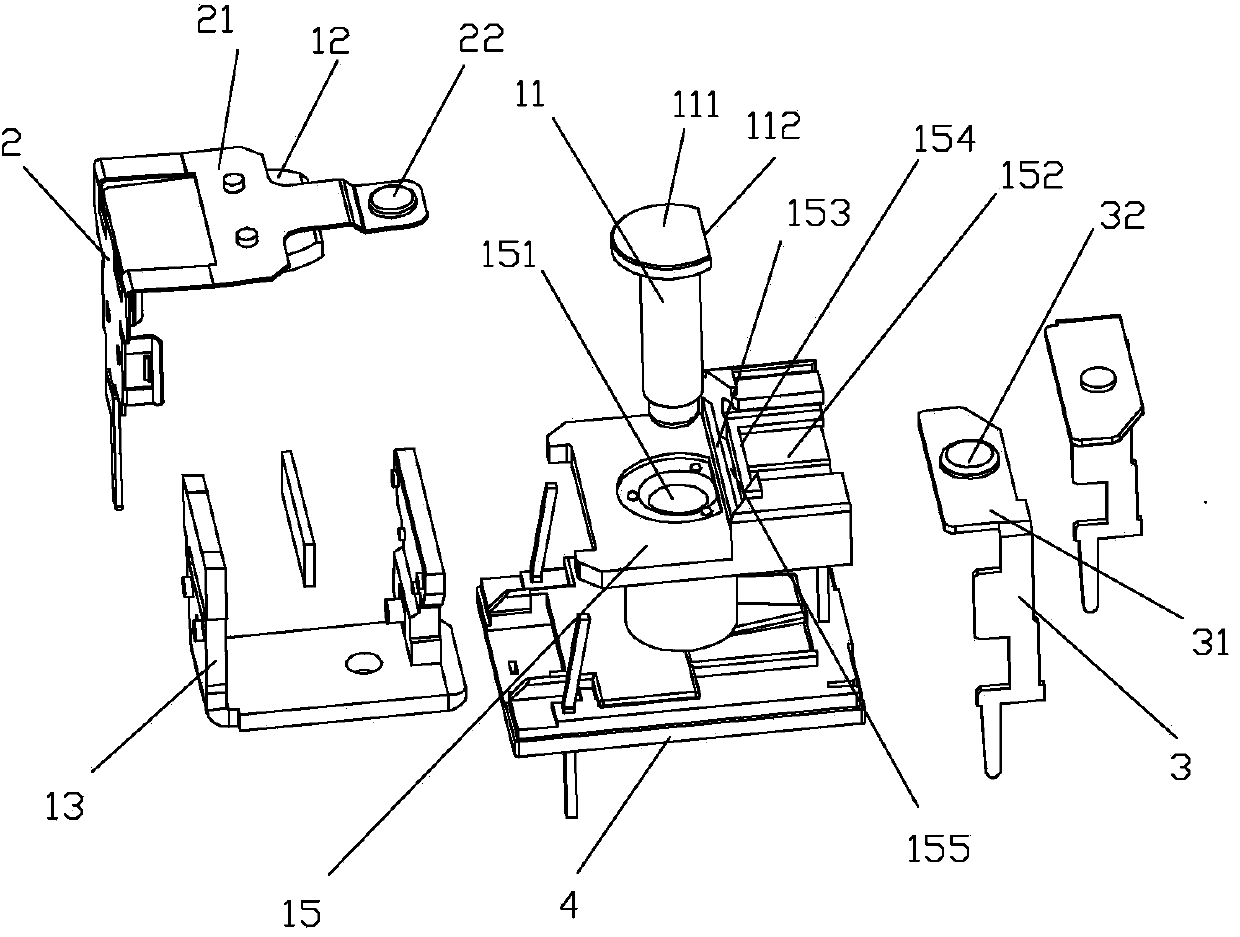

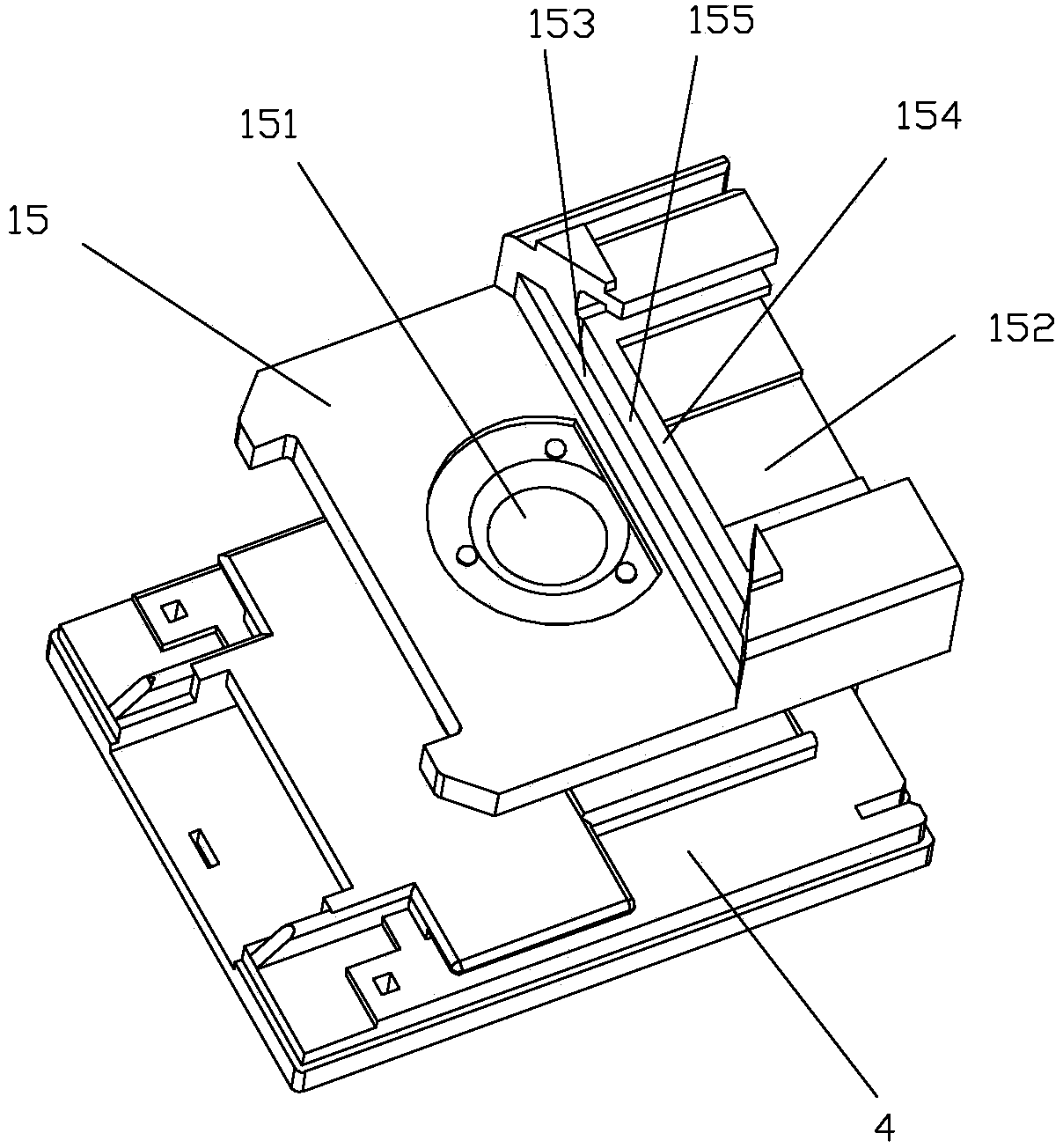

[0025] Examples, see Figure 1 to Figure 7 As shown, a clapping electromagnetic relay of the present invention includes a magnetic circuit part 1, a moving spring part 2 and a static spring part 3; the magnetic circuit part 1 includes an iron core 11, an armature 12, a yoke 13 and a coil; The coil includes an enameled wire 14 and a coil frame 15, the enameled wire 14 is wound on the coil frame 15, and the coil frame 15 is installed on the base 4. In this embodiment, the coil frame 15 and the base 4 are integrally structured; the coil The frame 15 is provided with a vertical through hole 151, the iron core 11 is installed in the through hole 151 of the coil frame, the upper end of the iron core 11 is provided with a pole shoe 111, and the lower end of the iron core 11 is fixed with the yoke iron 13; 13 is L-shaped, the upper end constitutes the edge of the yoke 13, and the armature 12 can rotate along the edge of the yoke; the moving spring part 2 includes a moving reed 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com