A method for controlling corrosion grooves used for making texturing of solar cells

A technology of solar cells and control methods, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as high manufacturing costs, high maintenance costs, and difficult maintenance, and achieves reduced purchase costs, simple maintenance, and improved technology. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

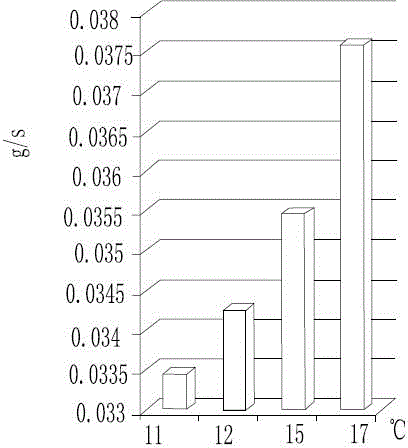

[0030] Example 2, (2) Set the temperature of the corrosion tank to X=11.5 degrees Celsius; (2) Collect the actual temperature of the current corrosion tank as Y=11.9 degrees Celsius; (3) The coefficient α in this corrosion solution is 0.125; ( 4) Set the initial speed of the corrosion tank roller movement as V 1 =2 m / min; (5) According to the formula V 2 =V 1 +α(Y-X) to obtain the actual speed V that controls the movement of the corrosion tank roller 2 =2+0.125 (11.9-11.5)=2.05 m / min.

[0031]By using the method, the control system has lower requirements on the temperature control accuracy of the refrigerator, and a simple domestic refrigerator can also meet the process requirements, because the control circuit is simple, the purchase cost can be significantly reduced, and the selection range of the refrigerator is wider. It is easier and more convenient to maintain and repair during use. The present invention uses the actual temperature detected by the sensor and the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com