Organic silicon shampoo and preparation method thereof

A silicone and shampoo technology, applied in medical preparations containing active ingredients, hair care, pharmaceutical formulations, etc., can solve the problems of disordered body hormone levels, clogged pores, scalp residues, etc., to achieve full luster, not easy to break, The effect of increasing water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

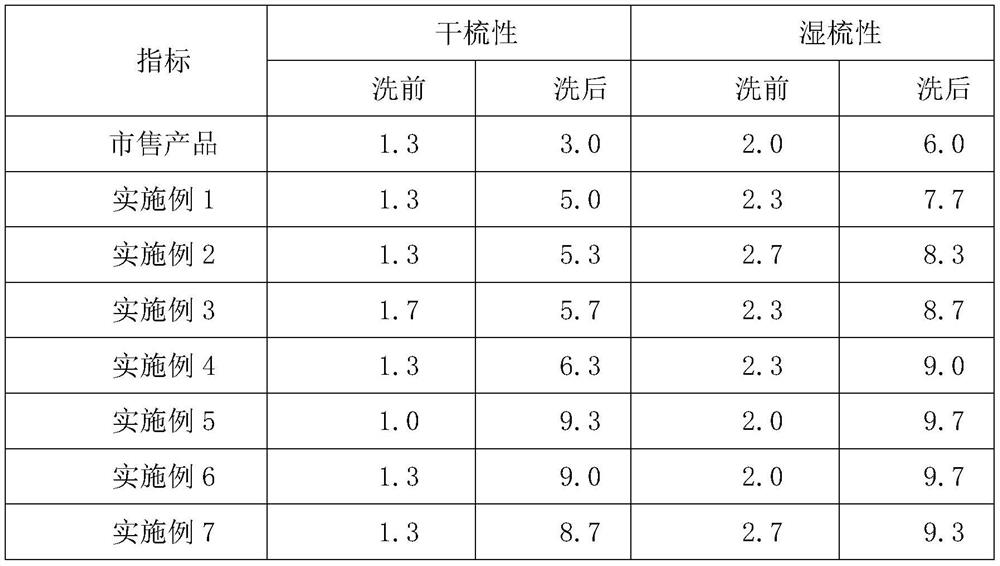

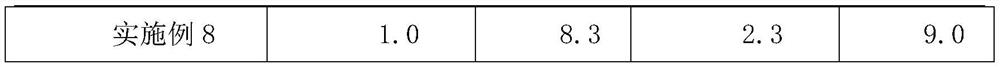

Examples

Embodiment 1

[0038] A preparation method of organosilicon shampoo, prepared according to the following steps from the following raw materials in parts by weight:

[0039] (1) Weigh the premixed component raw materials according to the following parts by weight: 18.0 parts of sodium methyl cocoyl taurate, 5.0 parts of sodium α-alkenyl sulfonate, 12.0 parts of sodium lauryl ether sulfate, coconut oil 5.0 parts of amidomethyl MEA, 3.0 parts of ethylene glycol distearate, 4.0 parts of sodium isostearyl lactylate, 2.0 parts of stearamidopropyl dimethylamine, guar gum hydroxypropyl trimethyl chloride 2.0 parts of ammonium chloride, 2.0 parts of cationic cellulose and 24.1 parts of water; pre-disperse the guar gum hydroxypropyltrimethylammonium chloride and cationic cellulose with an appropriate amount of water, then add, mix and stir, and heat at 70°C to 80°C , Stir speed to 20-30RPM, fully stir for 10-30min to form a uniform mixture;

[0040] (2) Weigh the organic silicon phase component raw m...

Embodiment 2

[0043] A preparation method of organosilicon shampoo, prepared according to the following steps from the following raw materials in parts by weight:

[0044] (1) Weigh the premixed component raw materials according to the following parts by weight: 18.0 parts of sodium methyl cocoyl taurate, 5.0 parts of sodium α-alkenyl sulfonate, 12.0 parts of sodium lauryl ether sulfate, coconut oil 5.0 parts of amidomethyl MEA, 3.0 parts of ethylene glycol distearate, 4.0 parts of sodium isostearyl lactylate, 2.0 parts of stearamidopropyl dimethylamine, guar gum hydroxypropyl trimethyl chloride 2.0 parts of ammonium chloride, 2.0 parts of cationic cellulose and 23.1 parts of water; pre-disperse the guar gum hydroxypropyltrimethylammonium chloride and cationic cellulose with an appropriate amount of water, then add, mix and stir, and heat at 70°C to 80°C , Stir speed to 20-30RPM, fully stir for 10-30min to form a uniform mixture;

[0045] (2) Weigh the organic silicon phase component raw m...

Embodiment 3

[0048] A preparation method of organosilicon shampoo, prepared according to the following steps from the following raw materials in parts by weight:

[0049] (1) Weigh the premixed component raw materials according to the following parts by weight: 18.0 parts of sodium methyl cocoyl taurate, 5.0 parts of sodium α-alkenyl sulfonate, 12.0 parts of sodium lauryl ether sulfate, coconut oil 5.0 parts of amidomethyl MEA, 3.0 parts of ethylene glycol distearate, 4.0 parts of sodium isostearyl lactylate, 2.0 parts of stearamidopropyl dimethylamine, guar gum hydroxypropyl trimethyl chloride 2.0 parts of ammonium chloride, 2.0 parts of cationic cellulose and 22.1 parts of water; pre-disperse the guar gum hydroxypropyltrimethylammonium chloride and cationic cellulose with an appropriate amount of water, then add, mix and stir, and heat at 70°C to 80°C , Stir speed to 20-30RPM, fully stir for 10-30min to form a uniform mixture;

[0050] (2) Weigh the organic silicon phase component raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com