Corn picking composite roller

A compound roller and corn technology, applied in the direction of cutters, agricultural machinery and implements, applications, etc., can solve the problems of low operating efficiency of the whole machine and low efficiency of pulling stems, and achieve the effect of reducing effective blows and reducing grain damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

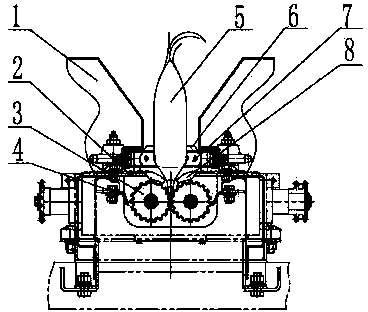

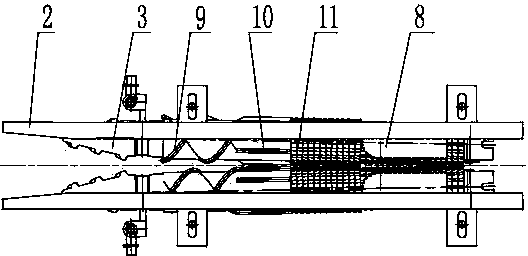

[0029] Attached figure 2 It can be seen that the structure of the present invention specifically includes two symmetrically arranged counter-rotating rollers with a gap between the two counter-rotating rollers. The left end of the counter-rotating roller is a guide cone, and the right side of the guide cone is a stem section 10, which The counter-rotating rollers at section 10 are evenly distributed in the circumferential direction with shifting teeth, which extend along the radial direction of the counter-rotating roller, and the structure of the shifting teeth is a long steel sheet. An introduction section 9 is provided between the stem pulling roller 10 and the guide cone, and a guide spiral is arranged on the outer wall of the rotating roller at the introduction section 9. A stripping section 11 is provided on the right side of the pulling stem section 10, the surface of the counter-rotating roller at the stripping section 11 is a toothed structure made of rubber material, ...

Embodiment 2

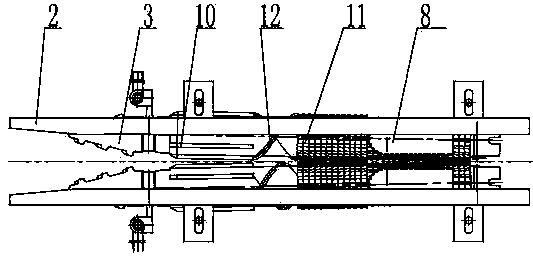

[0033] As attached image 3 As shown, on the basis of the first embodiment, a feeding section 12 is added between the pulling stem section 10 and the peeling section 11, and the feeding section 12 is provided with guiding spiral edges on the outer wall of the roller.

Embodiment 3

[0035] As attached Figure 4 As shown, this structure is based on the second embodiment, the introduction section 9 is eliminated, and the introduction section 9 is replaced by the spiral edge of the guide cone to realize the feeding of straw.

[0036] For the composite roller of the present invention, it is necessary to add two reel chains 7 during use. The two reel chains 7 are symmetrically arranged above the counter-rotating roller. The reel chain 7 is a closed chain, and the outer sides of the chains are respectively The reel is composed of the auxiliary plate 13 and the scraper 6. The chain is driven by three sprockets, so that the front end of the chain forms a horn-shaped entrance, and the middle and rear parts are parallel sections.

[0037] In order to ensure that the straw on the counter-rotating roller sticks to the surface of the roller, a grass cleaning knife 4 is added. The grass cleaning knife 4 is arranged on the outside of the counter-rotating roller and fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com