Movable type tower crane

A technology of mobile tower cranes and booms, which is applied to cranes and other directions, and can solve problems such as short construction period, uneconomical fixed tower cranes, and small lifting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

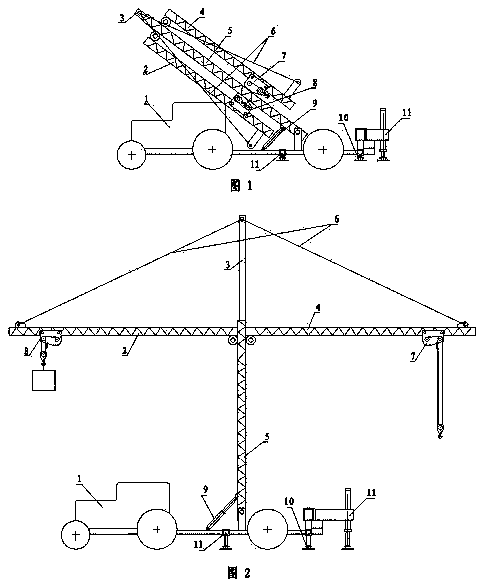

[0012] exist figure 1 and figure 2 In the mobile tower crane shown, the base frame 5 is hinged on the frame of the locomotive 1, and the use of the locomotive 1 facilitates the transportation of the tower crane installed on it. 4 and the balance arm 2, the underframe 5, the working arm 4 and the balance arm 2 are all arranged in a frame structure. The overall rigidity of the underframe 5 of this frame structure is relatively high, and the overall rigidity of the underframe 5 is ensured during production. Under the premise, it can be made as high as possible, so that the hoisting height of the tower crane can be increased, and the hoisted object can be hoisted to more than three floors, thus overcoming the problem of low hoisting height of the boom crane. The defect has the effect of high lifting height; a boom extension device 3 is arranged in the inner cavity on the top of the chassis 5, and the boom extension device 3 is a telescopic oil cylinder. The boom extension device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com