Composite flame retardant paper honeycomb insulating external wall panel for cold regions and installation method

A composite flame-retardant technology in cold regions, applied to chemical instruments and methods, walls, synthetic resin layered products, etc., can solve the problems of external wall panels and wall panels not equipped with thermal insulation and waterproofing, so as to meet environmental protection requirements and reduce The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

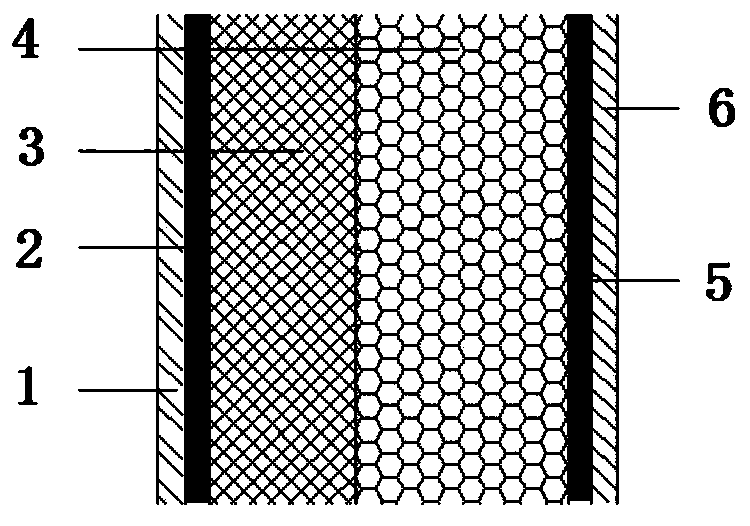

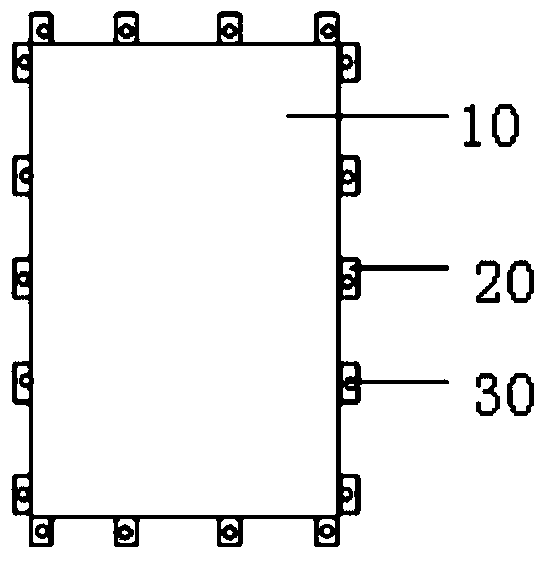

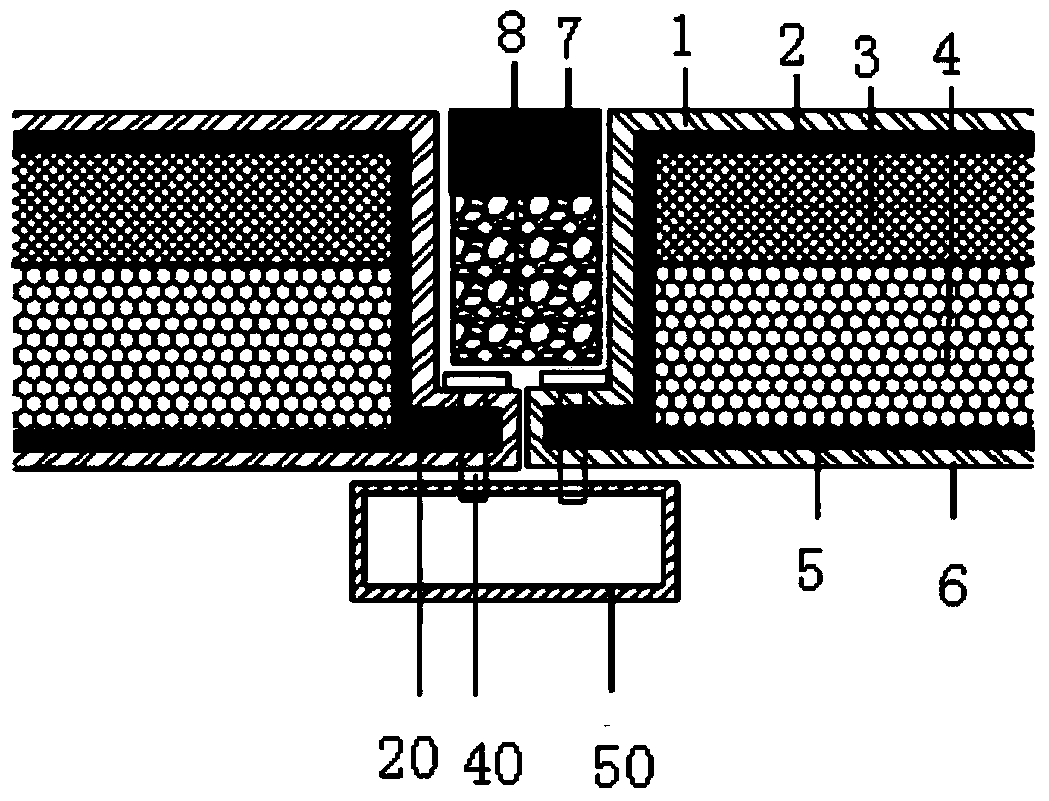

[0023] Such as figure 1 , figure 2 , image 3 As shown, a composite flame-retardant paper honeycomb thermal insulation exterior wall panel 10 in cold regions of the present invention includes an internal core material, and the internal core material includes a waterproof rock wool thermal insulation board 3 and a waterproof rock wool thermal insulation board laminated on the waterproof rock wool thermal insulation board 3 The lower flame-retardant paper honeycomb panel 4; the outer skin is wrapped around the inner core material. Waterproof coatings 2 and 5 are provided between the outer skin and the inner core material. The waterproof rock wool insulation board 3 and the fire-retardant paper honeycomb board 4 are bonded by silicone structural glue. The waterproof rock wool insulation board 3 has a thickness of 50mm. The flame-retardant paper honeycomb panel 4 has a thickness of 80 to 100mm. The outer skin surrounds a closed space, and the inner core material is accommoda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap