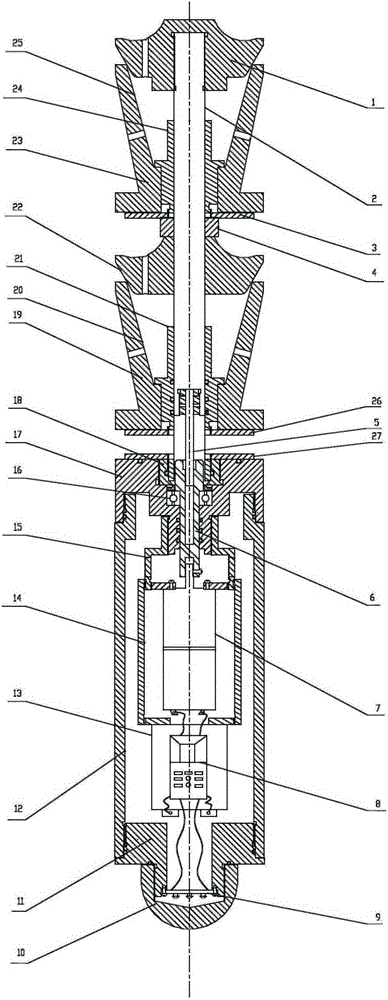

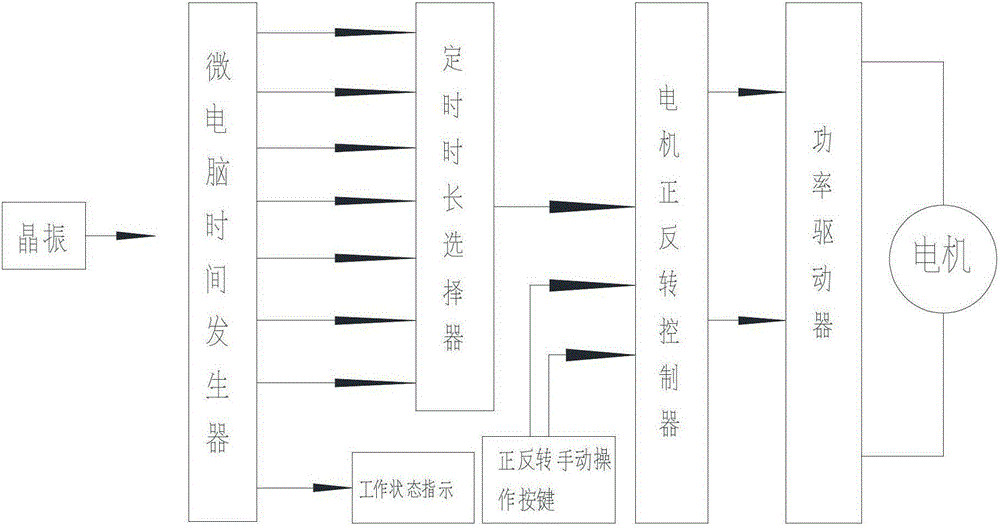

In-pipe downhole variable-diameter limiter blocking and isolating device

A technology of isolation device and limiter, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of delayed sound measurement and resistance, and achieves accurate and controllable expansion and contraction, Avoid the effect of delayed sound change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Apricot 3-But 4-E68 well

[0018] The design depth of the well: 1239 meters, the position of the cement surface control tool: 894 meters. On September 16, 2012, variable diameter cementing rubber plugs were used for cementing construction. The designed replacement volume of the second replacement: 11.4 cubic meters, and the actual replacement volume of the second replacement: 11.4 cubic meters. Acoustic change detection was carried out after 20 days, and logging was successful once.

[0019] The designed replacement volume of the second replacement in this well is consistent with the actual replacement volume, indicating that the variable diameter cementing rubber plug rubber body has a high degree of contact with the casing wall, which effectively separates and seals the drilling fluid in the casing from the clear water and ensures that the ball is closed The secondary displacement fluid runs synchronously to avoid the retention of drilling fluid in the casing....

Embodiment 2

[0020] Example 2: Apricot 3-40-E66 well

[0021] The design depth of the well: 1241 meters, the position of the cement surface control tool: 894 meters. Using variable diameter cementing rubber plugs for cementing construction, the designed replacement volume of the second replacement: 11.4 cubic meters, and the actual replacement volume of the second replacement: 11.4 cubic meters. Acoustic change detection was carried out after 20 days, and logging was successful once.

[0022] The designed replacement volume of the second replacement in this well is consistent with the actual replacement volume, indicating that the variable diameter cementing rubber plug rubber body has a high degree of contact with the casing wall, which effectively separates and seals the drilling fluid in the casing from the clear water and ensures that the ball is closed The secondary displacement fluid runs synchronously to avoid the retention of drilling fluid in the casing. A successful acoustic varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com