High-heat release gas compressor

A compressor and gas outlet technology, applied in pressure pumps, mechanical equipment, machines/engines, etc., can solve the problems of rising gas temperature and affecting the degree of gas compression, and achieve the effect of low shape requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

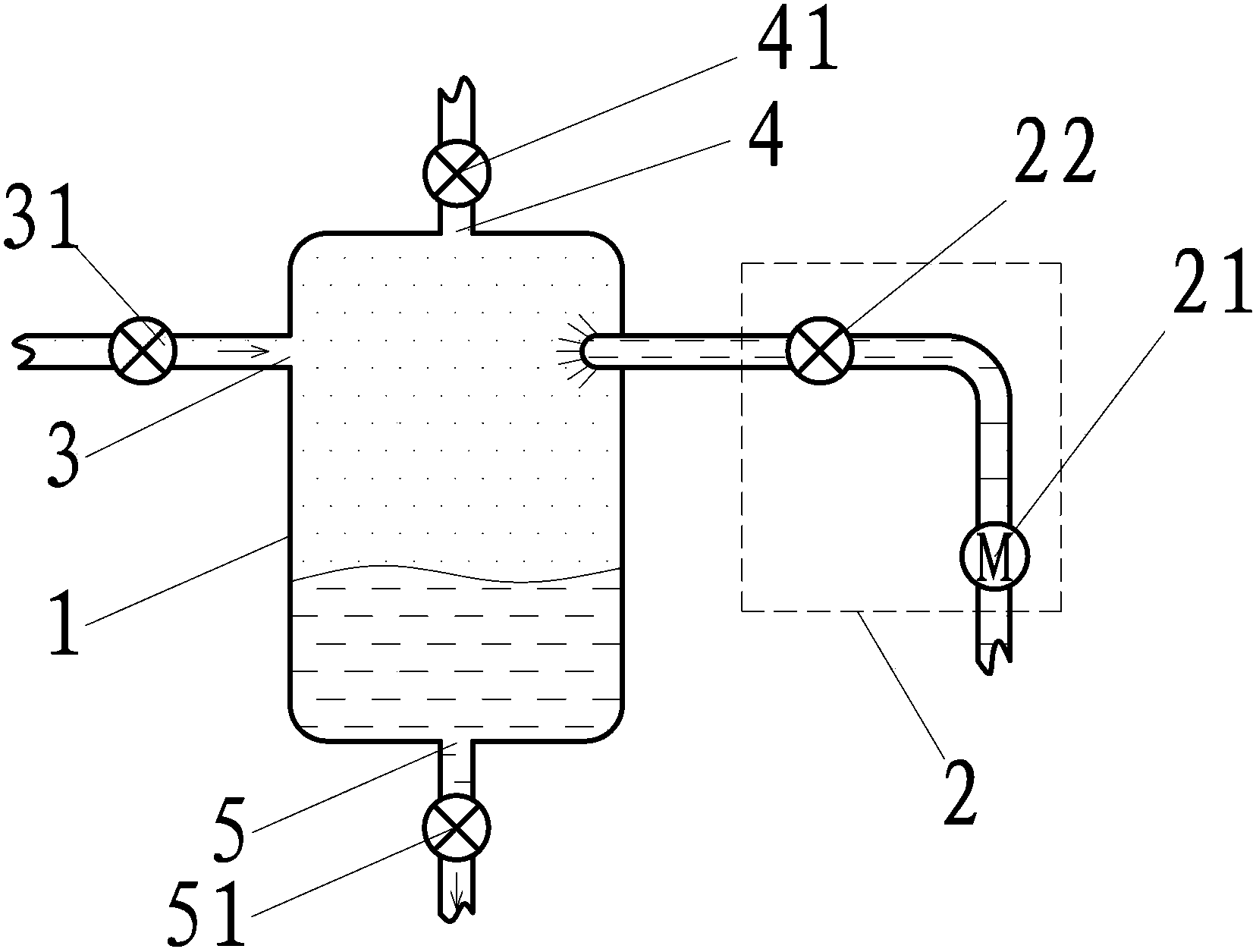

[0028] Such as figure 1 The large exothermic compressor shown includes a container 1 and a timing liquid supply unit 2. The container 1 is provided with a gas inlet 3, a gas outlet 4, a liquid outlet 5 and a liquid inlet, and a control is provided at the gas inlet 3. Valve 31. A control valve 41 is provided at the gas outlet 4, a control valve 51 is provided at the liquid outlet 5, and the liquid outlet of the timing liquid supply unit 2 is in communication with the liquid inlet.

[0029] The working engineering of this embodiment is:

[0030] 1) Air intake process: close the control valve 41, open the control valve 31 and the control valve 51, the gas enters the container 1 through the gas inlet 3 until the liquid in the container 1 is completely Discharge, the control valve 51 is closed, and the gas continues to be filled into the container 1 to reach the set pressure state;

[0031] 2) Compression process: the control valves 31, 41, 51 are closed, the timing liquid supply unit 2 ...

Embodiment 2

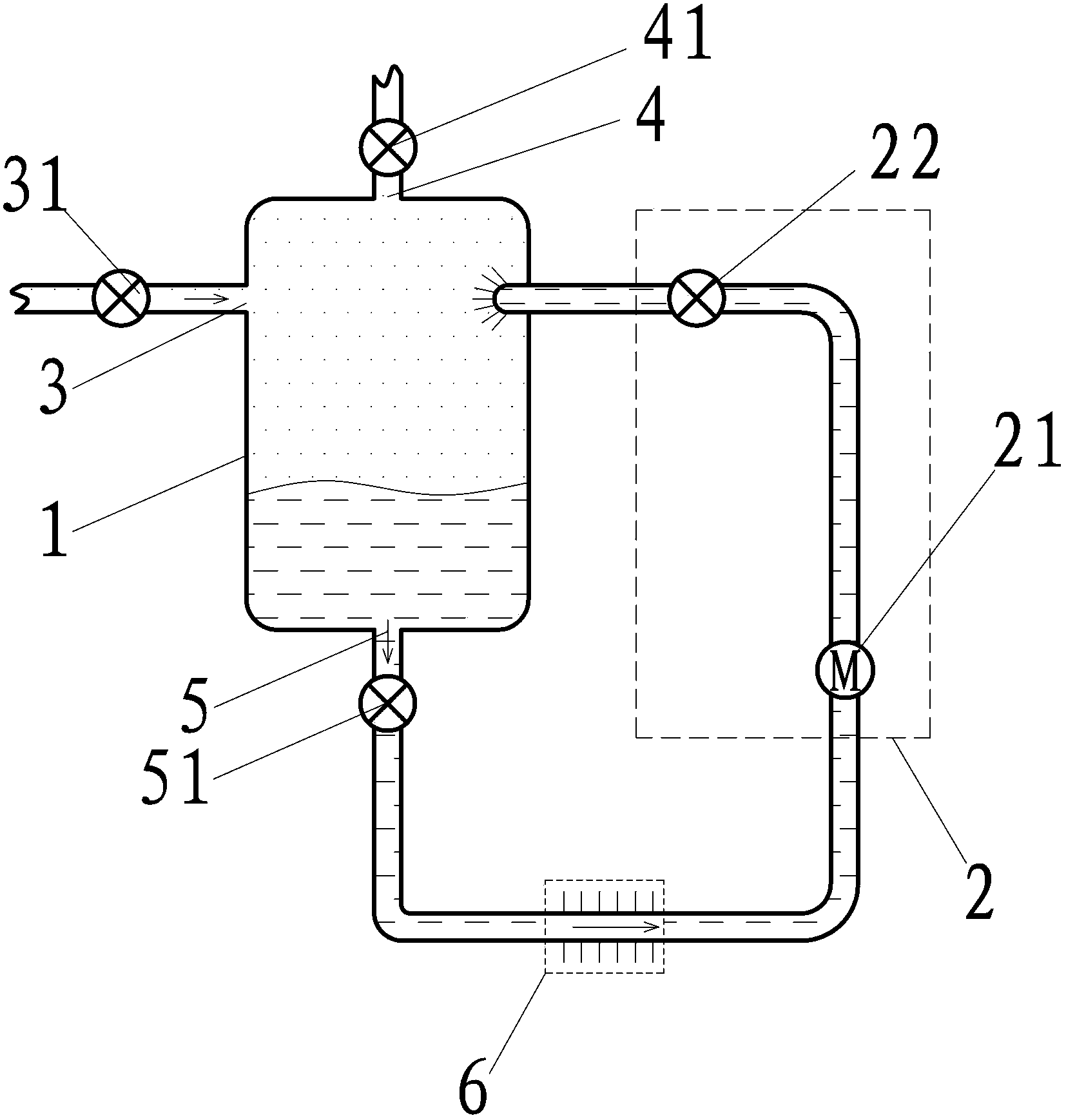

[0034] Such as figure 2 The large exothermic compressor shown, on the basis of Embodiment 1, makes the timing liquid supply unit 2 include a liquid pump 21 and a timing control valve 22, and the liquid pump 21 is controlled by the timing The valve 22 communicates with the liquid inlet, the liquid outlet 5 communicates with the liquid inlet of the timing liquid supply unit 2, and a cooler is provided on the communication channel between the liquid outlet 5 and the liquid pump 21 6.

[0035] Alternatively, the cooler 6 may be arranged on the communication passage between the liquid pump 21 and the timing control valve 22; or may be arranged on the timing control valve 22 and the container instead. 1 on the communication channel between the liquid inlets, or the cooler 6 may not be provided.

[0036] As an alternative embodiment, the liquid outlet 5 of the container 1 may not communicate with the liquid inlet of the timing liquid supply unit 2, and the cooler 6 may not be provided a...

Embodiment 3

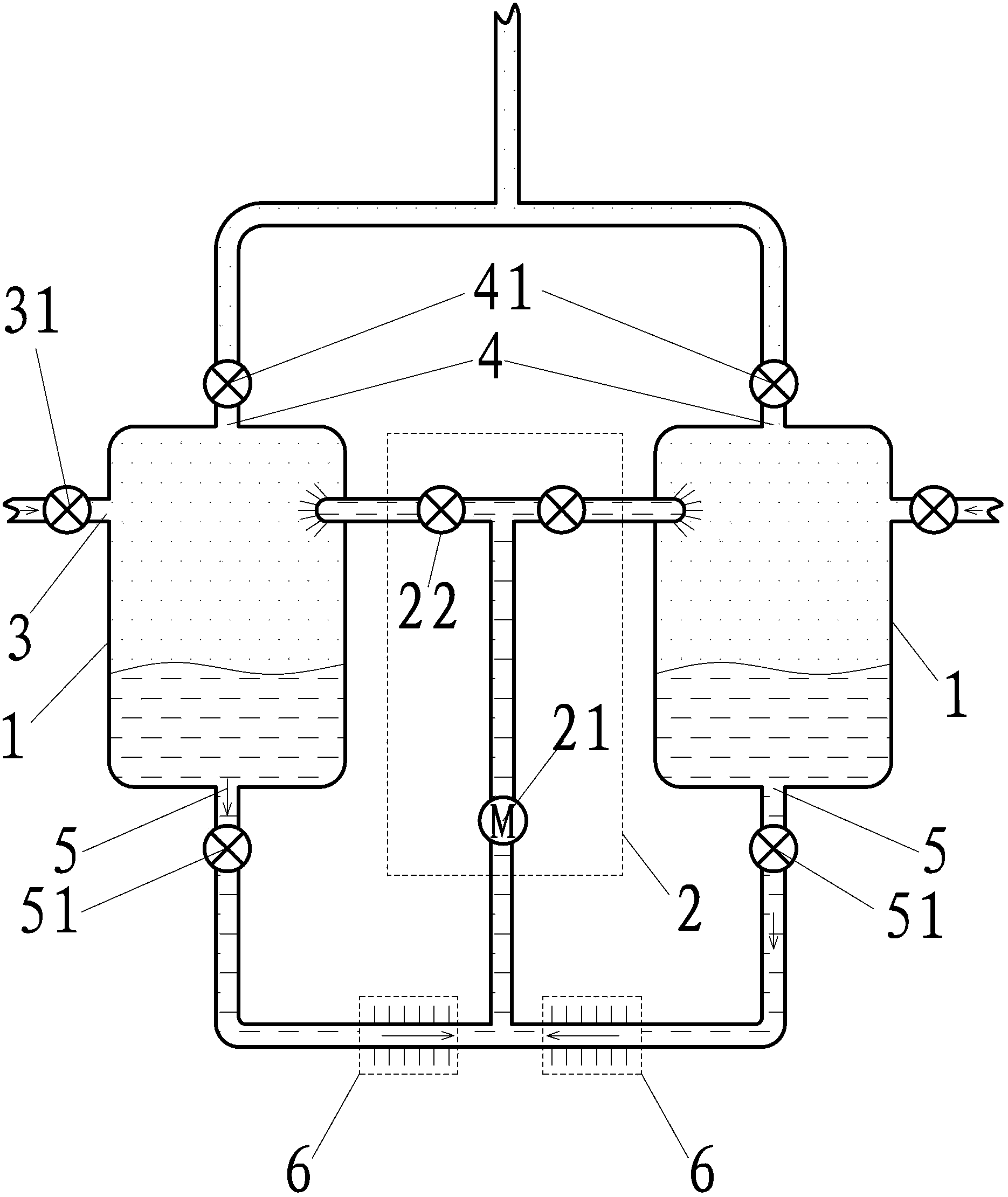

[0039] Such as image 3 In the large exothermic compressor shown, on the basis of the second embodiment, one of the containers 1 is added, two of the containers 1 are arranged in parallel, and the two containers 1 are supplied by one of the timing liquids Unit 2 is connected.

[0040] As a transformable embodiment, the number of containers 1 can be changed to three or more in parallel;

[0041] In all embodiments of the present invention, two or more containers 1 can be provided with reference to this embodiment, so that the two or more containers 1 share the same timing liquid supply unit 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com