Verification device based on belt-driven four-wheel aligner

A four-wheel aligner and verification device technology, which is used in wheel testing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the drawings:

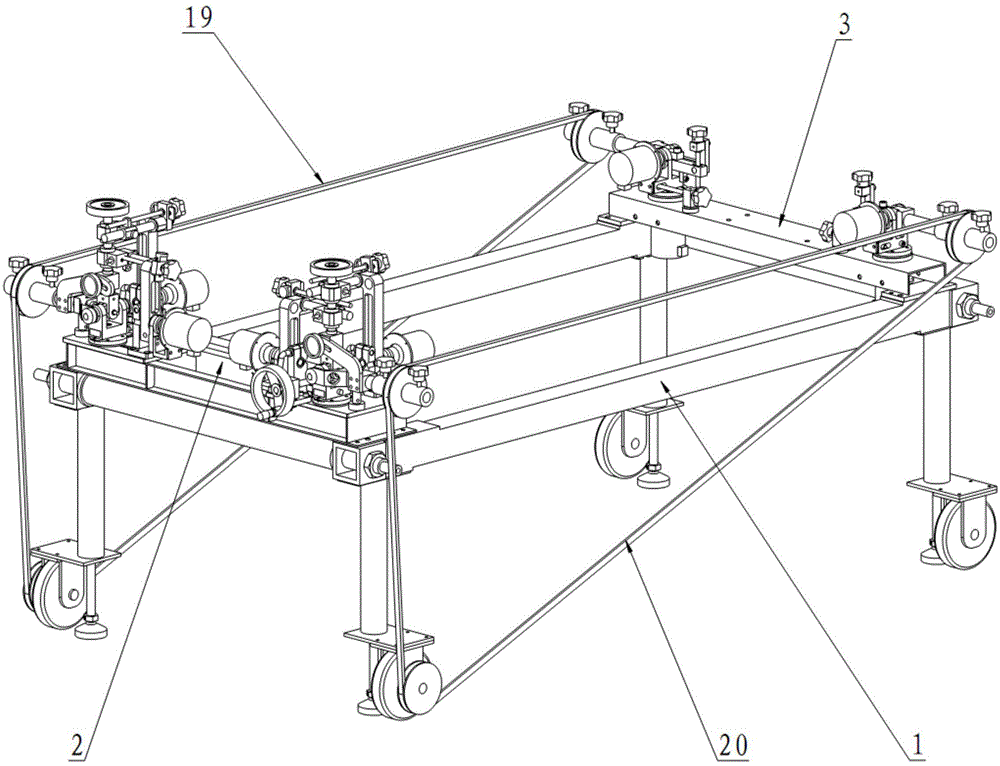

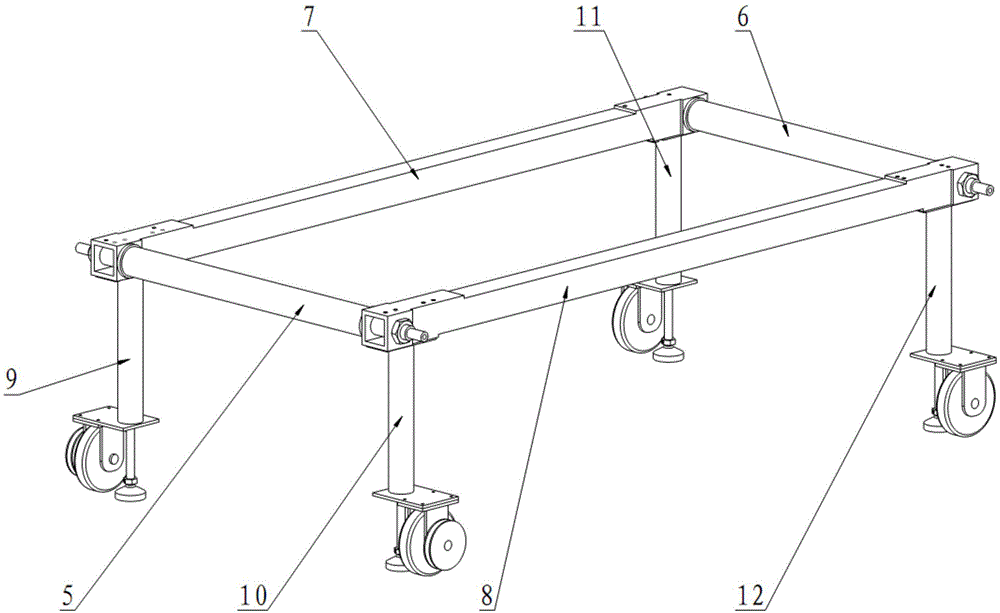

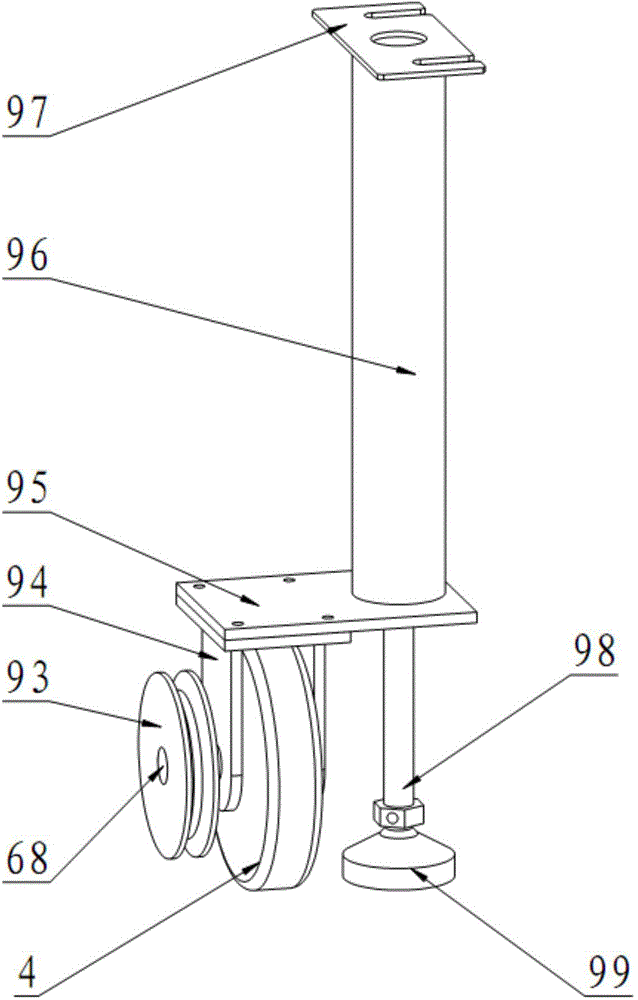

[0068] Refer to figure 1 , The belt-driven four-wheel aligner verification device of the present invention is mainly composed of toe zero inspection frame 1, front frame inspection part 2, back frame inspection part 3 and belt transmission device (including right belt transmission device 19 and left The belt drive 20) is composed. The toe-toe zero inspection frame 1 is used as the installation base of the front-end frame inspection part 2 and the back-end frame inspection part 3 to complete the inspection of the toe-toe zero point of the four-wheel alignment instrument; the front frame inspection part 2 is installed on the toe-toe zero inspection frame 1 The middle right side beam 7 and the left side beam 8 are fixedly connected with bolts on the front mounting platform to complete the caster angle, kingpin inclination angle, toe angle, camber angle and wheel rotation angle of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com