Secondary standard device and method for natural gas large flow real flow calibrating

A secondary standard, high-flow technology, used in measuring devices, testing/calibration devices, liquid/fluid solids measurement, etc. The effect of improving the measurement uncertainty of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

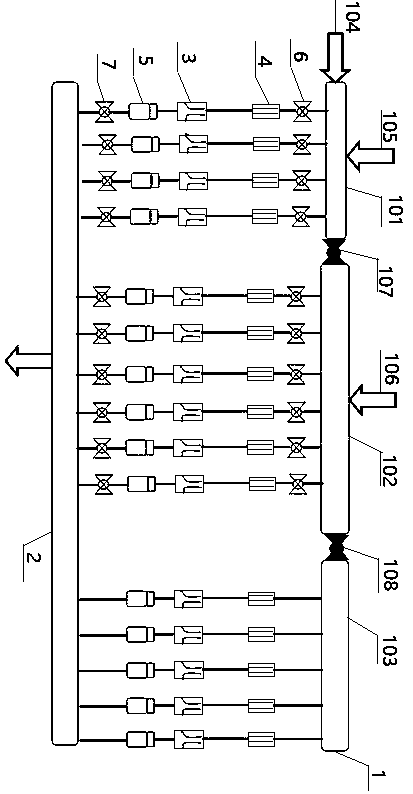

[0040]In order to overcome the problems of low accuracy and high cost investment in the existing test, the present invention provides such as figure 1 Shown is a secondary standard device and method for large-flow real-flow verification of natural gas. The present invention optimizes the group skid form of the secondary standard device, reduces the pipe capacity of the upstream manifold during small-flow verification, and improves the verification accuracy; The number of cut-off valves reduces investment and maintenance to a certain extent.

[0041] A secondary standard device for large-flow real-flow verification of natural gas, comprising an upstream header 1, a downstream header 2, and fifteen critical flow nozzles 3 arranged in parallel; the lower end of each critical flow nozzle 3 is connected to the downstream header 2, The upper end of each critical flow nozzle 3 communicates with the upstream header 1; each critical flow nozzle 3 is provided with a rectifier 4 upstream...

Embodiment 2

[0048] Based on the above embodiments, in this embodiment, the upstream header 1 includes a first upstream header 101, a second upstream header 102 and a third upstream header 103, and the first upstream header 1 is connected to the second upstream manifold 2 through the first manifold forced sealing ball valve 107, and the second upstream manifold 2 is connected to the third upstream manifold 3 through the second manifold forced sealing ball valve 108; the first upstream The header 101 is provided with two inlets, the first inlet 104 and the second inlet 105, the pipeline of the first inlet 104 is DN250, and the pipeline of the second inlet 105 is DN100; the second upstream header 102 is provided with a third inlet 106 , the third inlet 106 pipeline is DN150.

[0049] The first upstream header 101 is connected with four critical flow nozzles 3, the four critical flow nozzles 3 are DN50 nozzles, and the flow rates are respectively 10 m 3 / h, 20m 3 / h, 40m 3 / h and 80m 3 / h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com