Standard substance for calibrating magnification of industrial computed tomography (CT) system

An industrial computer and tomography technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of no electrical conductivity, no fixed position length measurement characteristics, no visible magnification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

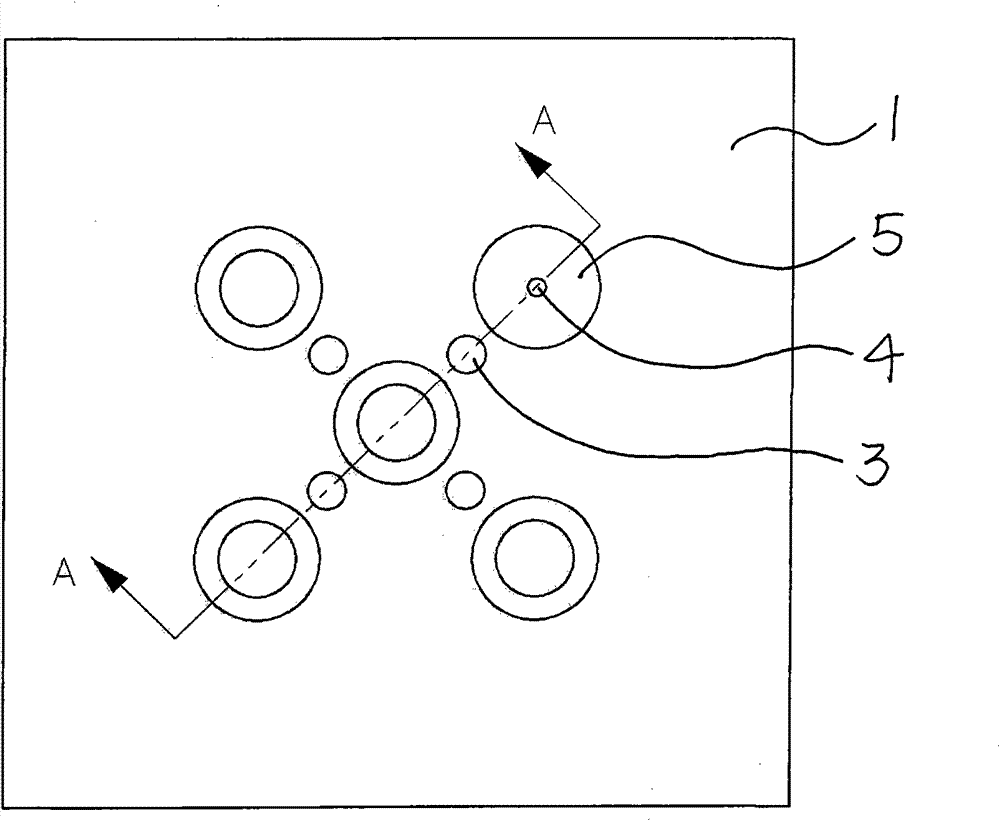

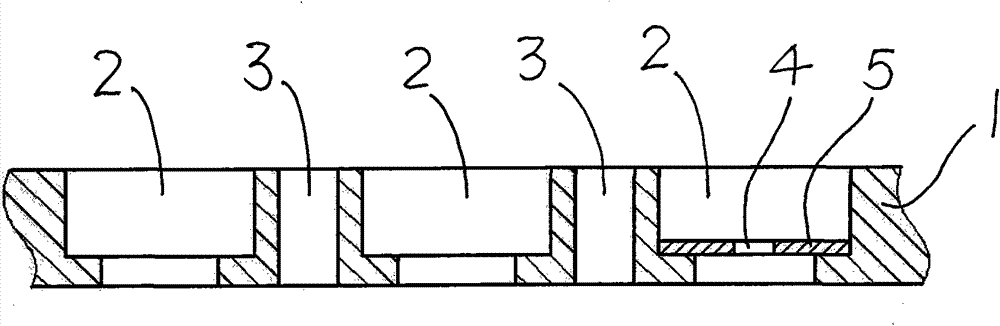

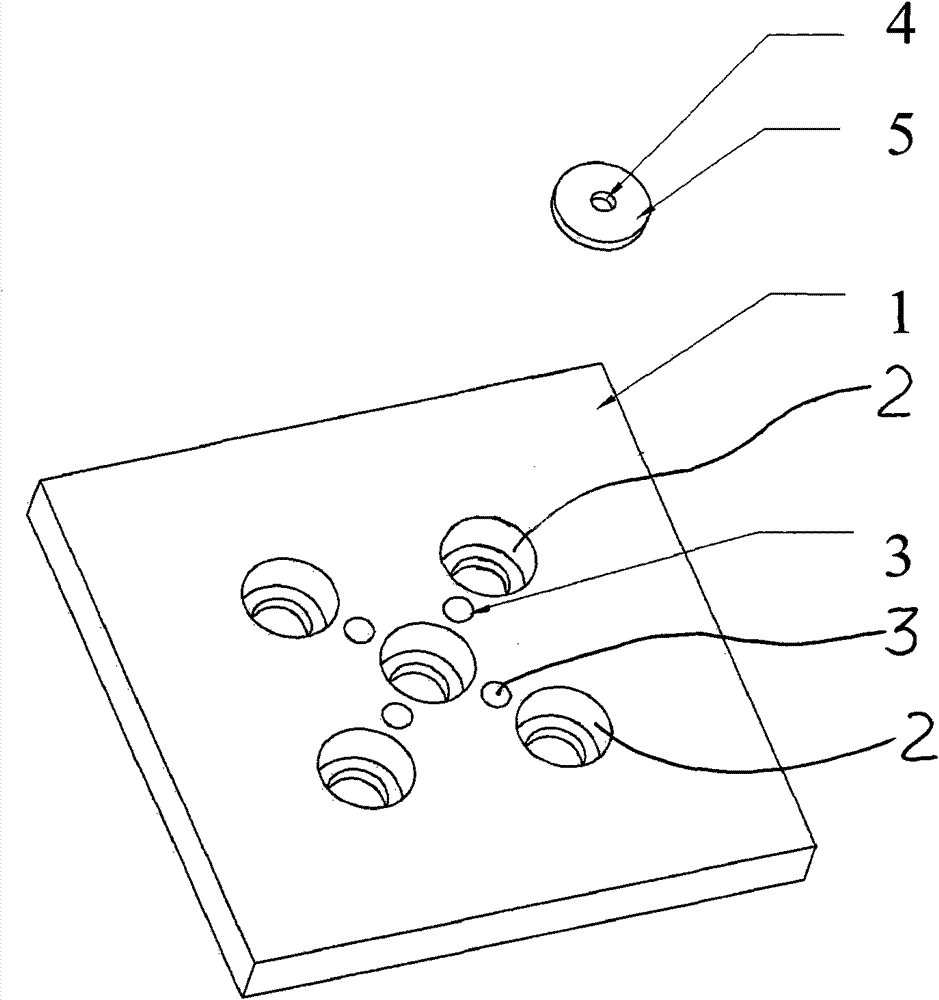

[0013] Embodiment 1: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 . The present invention needs to carry out value determination to the present invention before carrying out measurement standard value transfer, the value determination example of the present invention is as follows: put the certified standard substance of the present invention and the scanning electron microscope into the scanning electron microscope at the same time, the certified standard substance It was developed by Agar Science Company of the United Kingdom, and its traceability was determined by the National Physical Laboratory (NPL) of the United Kingdom. In this embodiment, the diameter of the through hole is selected as 0.2 mm or 0.5 mm. In the state of the low magnification and large field of view of the scanning electron microscope, the rotation function of the sample stage is used to place the connecting line direction between the center of the through hole and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com