Measuring method of mid-infrared light signal intensity in wide temperature environment

A technology of signal strength and measurement method, which is applied in the direction of photometry using electric radiation detectors, can solve problems such as insufficient dynamic range, measurement uncertainty, and small amplitude of measurement output signals, and achieves convenient calculation, simple steps, The effect of increasing the output signal amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

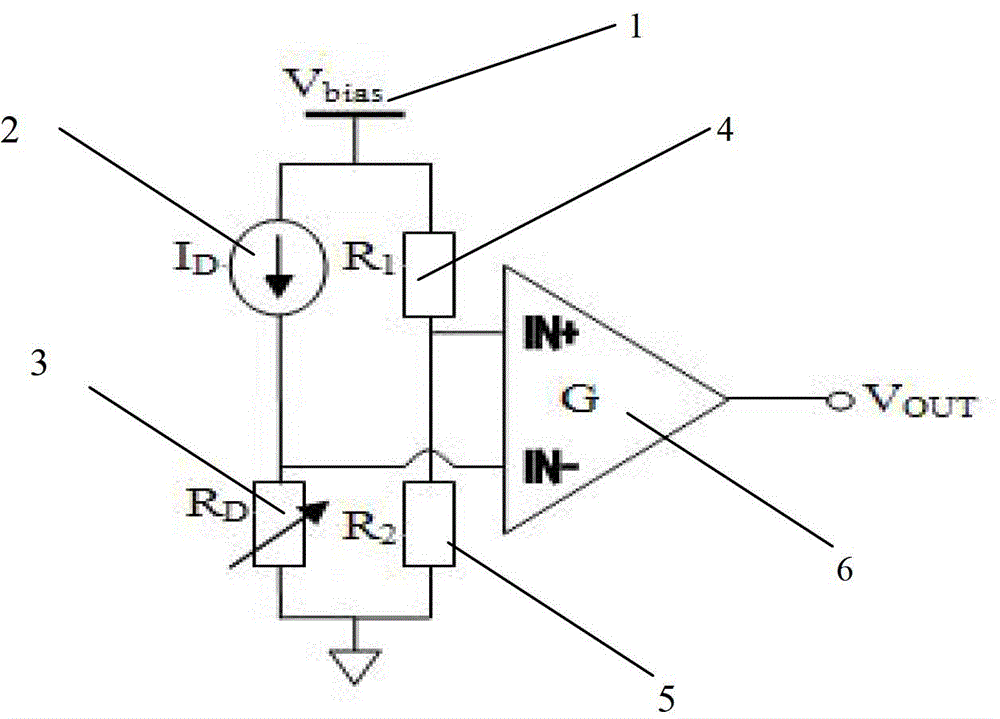

[0039] The measuring device of the mid-infrared optical signal intensity that the present invention adopts comprises mid-infrared photoconductive detector 3, driving circuit and signal acquisition recorder; Driving circuit is as figure 1 As shown, it includes an instrument amplifier unit and a constant current source unit. The constant current source unit is composed of a measuring arm and a trim arm. The measuring arm includes a constant current source 2 and a mid-infrared photoconductive detector 3. The positive terminal of the constant current source is connected to the bias voltage Source 1, the negative end is connected with one end of the detector 3 and the inverting input end of the instrumentation amplifier 6 at the same time, the other end of the detector 3 is grounded; the trim arm includes a bias resistor 4 and a trim resistor 5, and one end of the bias resistor 4 is connected to the bias Set the voltage source 1, the other end is connected with one end of the balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com