Sealing housings for plug-in contact elements

A plug-in contact and sealing part technology, which is applied in the direction of electrical components, multiple connection components, parts of connection devices, etc., can solve the problems of plug-in leakiness and damage to the sealing part, and achieve the effect of simple sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

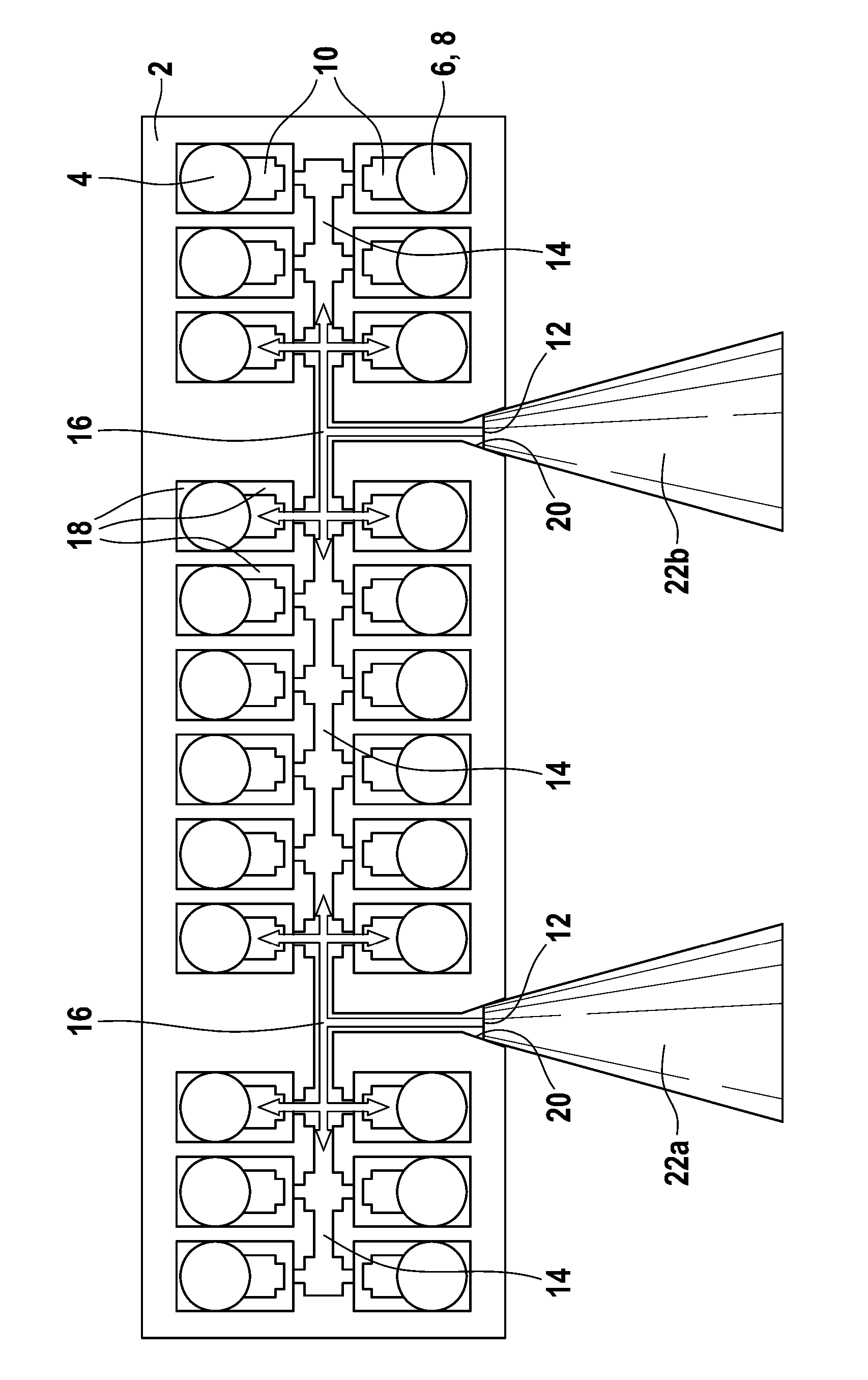

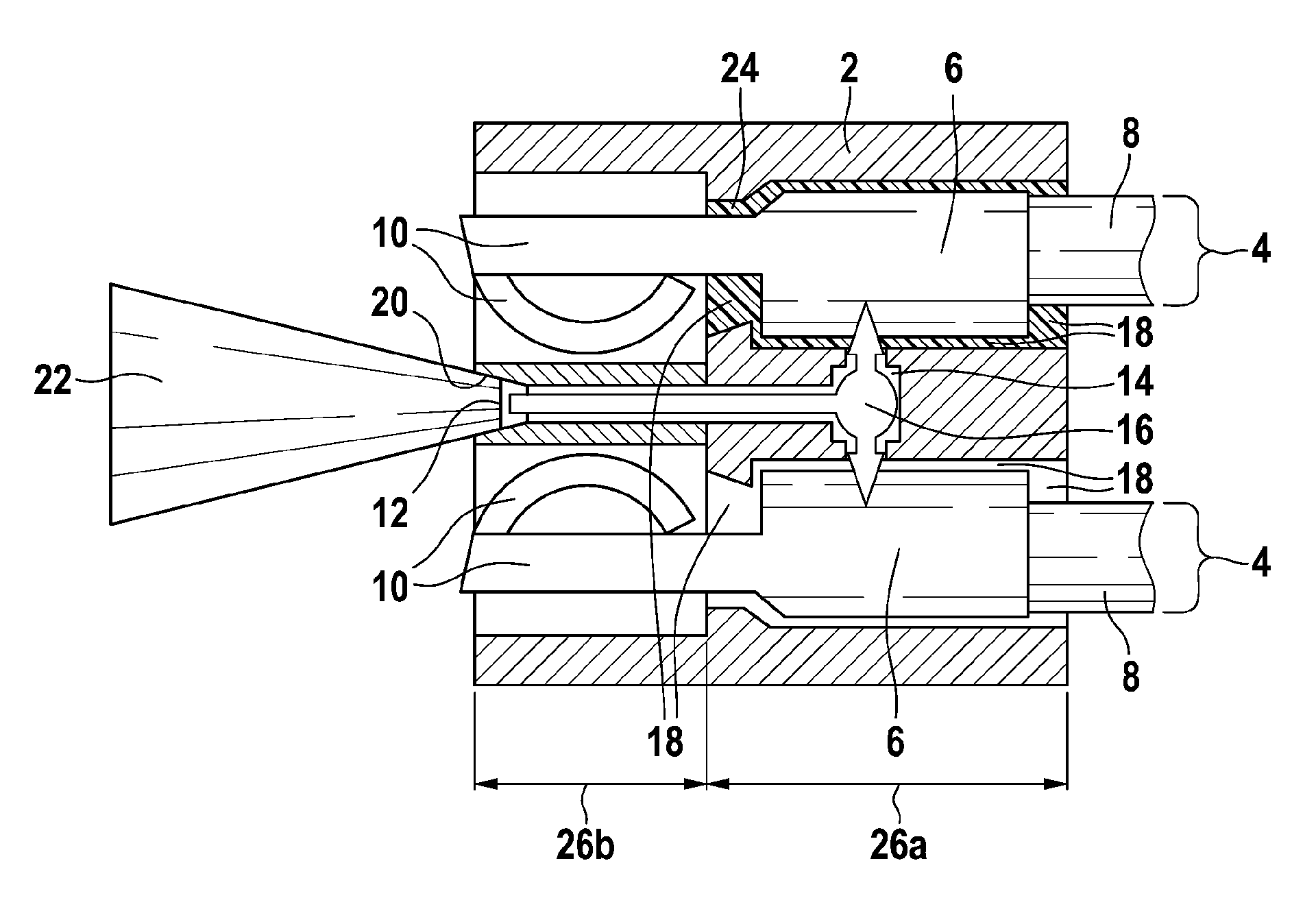

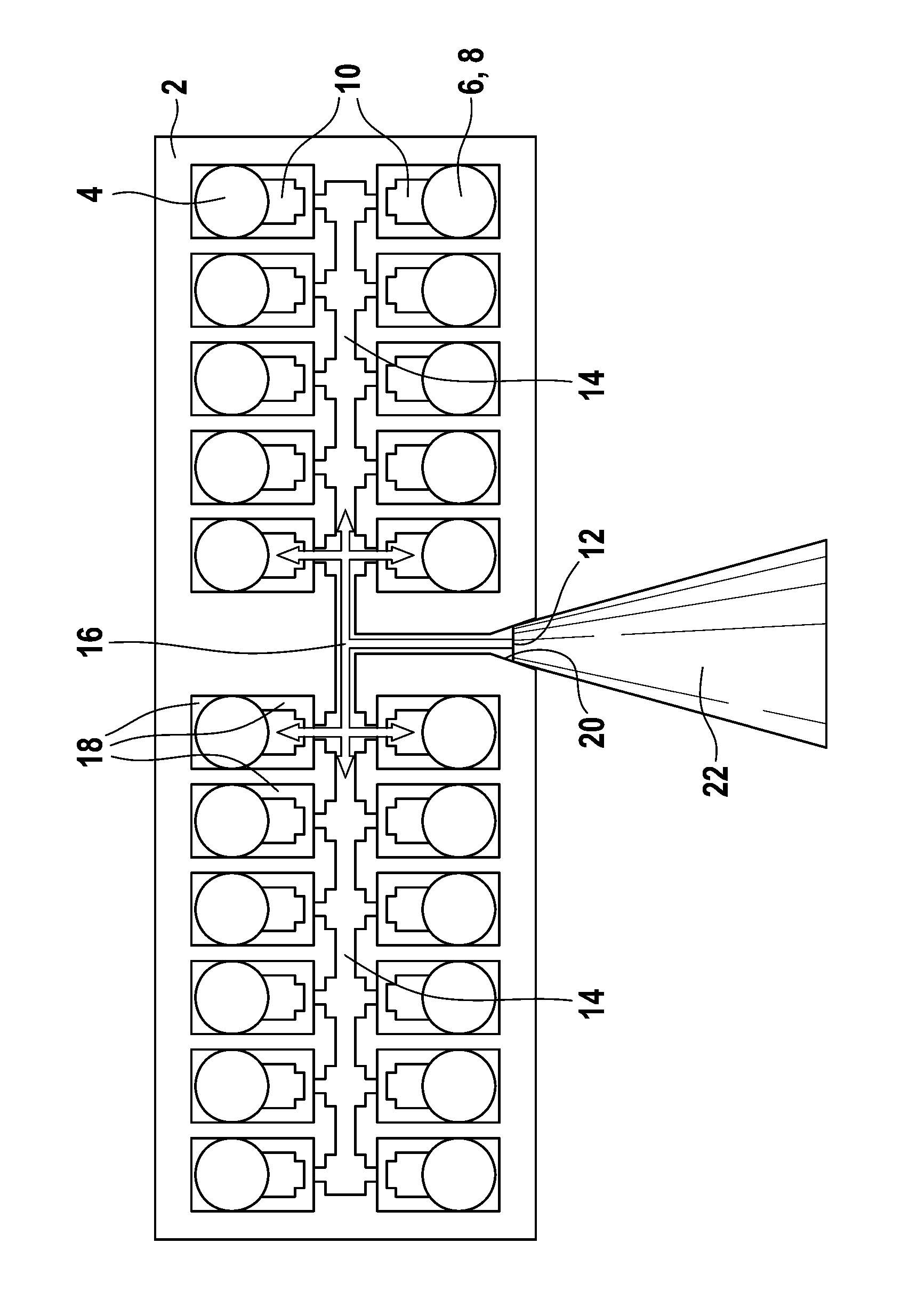

[0027] figure 1 The housing plug-in part of the present invention is shown as an example, and the housing plug-in part has a first opening at a central position from the front. The central position of the injection point is not mandatory, but can depend, inter alia, on equipment, small contact elements, high-power contact elements, unequipped receiving openings or hollow chambers, and mixing equipment.

[0028] The housing 2 has a central injection point 12 which is provided for introducing a flowable sealing material into the housing. Connected to the injection point 12 is a channel element 14 or flow channel 14 , which also runs through the housing 2 starting from the injection point 12 and connects the injection point 12 to the respective receiving opening in a flowable manner for the sealing material. 18 or cavities 18 are connected.

[0029] The only schematically shown connection between the air outlet or cavity 18 and the flow channel 14 enables the sealing material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com