Dust collecting bucket for dust catcher

A technology for dust collection barrels and vacuum cleaners, applied in the direction of suction filters, etc., can solve the problems affecting the use of vacuum cleaners and the effect of dust removal, affecting the product qualification rate, and complicated installation of dust collection barrels, so as to avoid dust leakage and simple and effective sealing , the effect of the best vacuuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

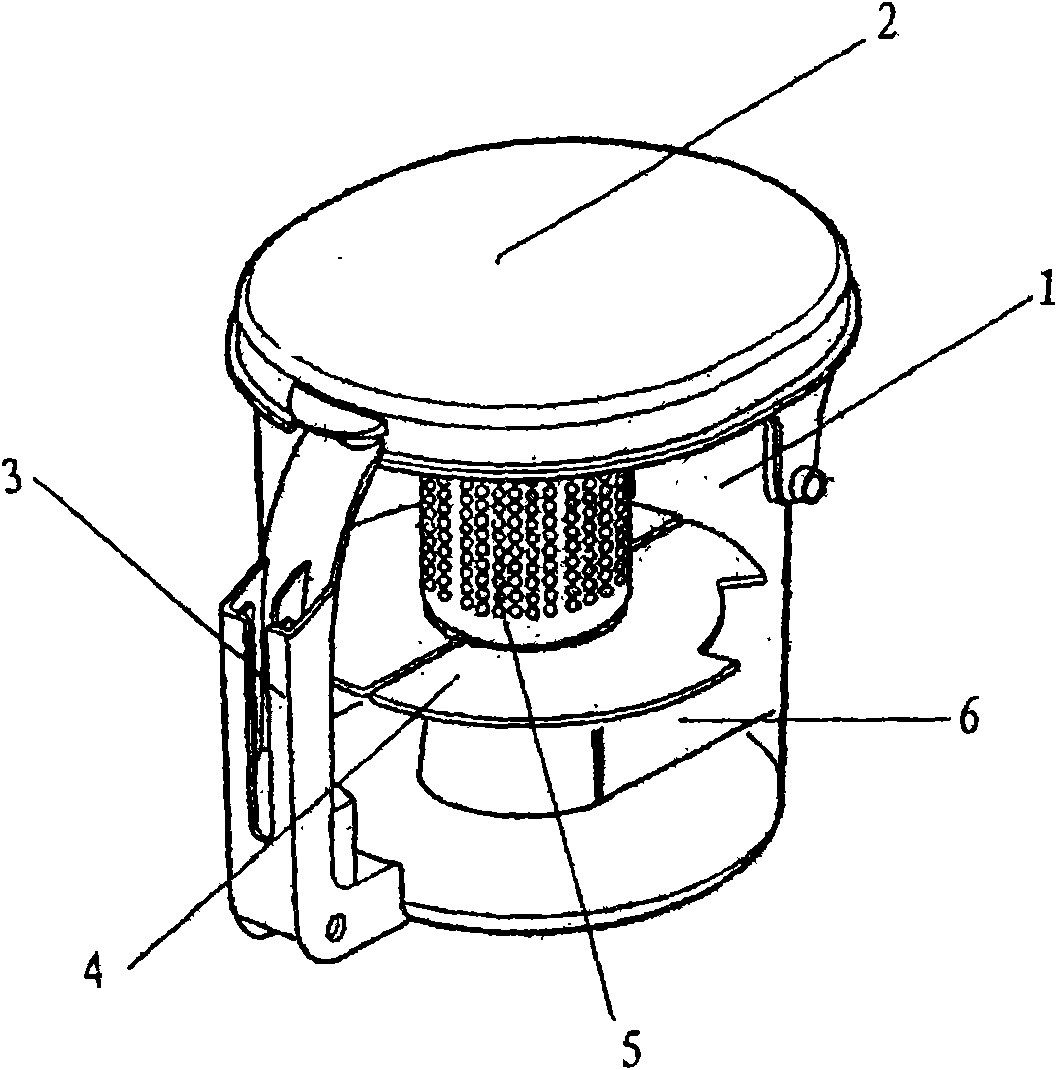

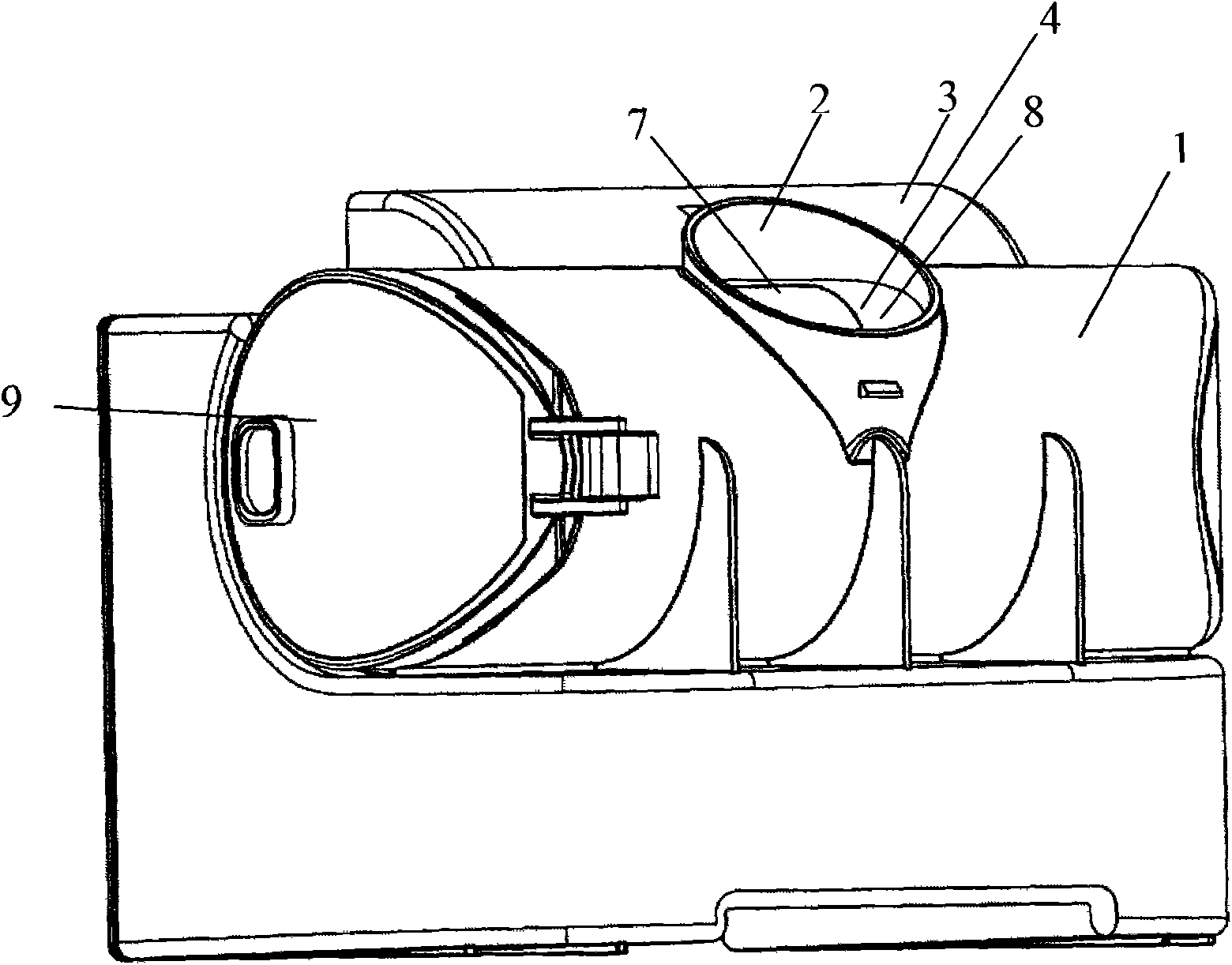

[0024] Such as figure 2 As shown, a dust collecting barrel of a vacuum cleaner provided by the present invention includes a barrel body 1, and an air inlet 2 and a handle 3 are arranged on the top of the barrel body 1. figure 2 Among them, the air inlet 2 is located directly in front of the handle 3, and the air inlet 2 is connected to the outside of the vacuum cleaner. By setting the handle 3, the dust collecting bucket of the present invention can be conveniently removed from the vacuum cleaner. loading and unloading.

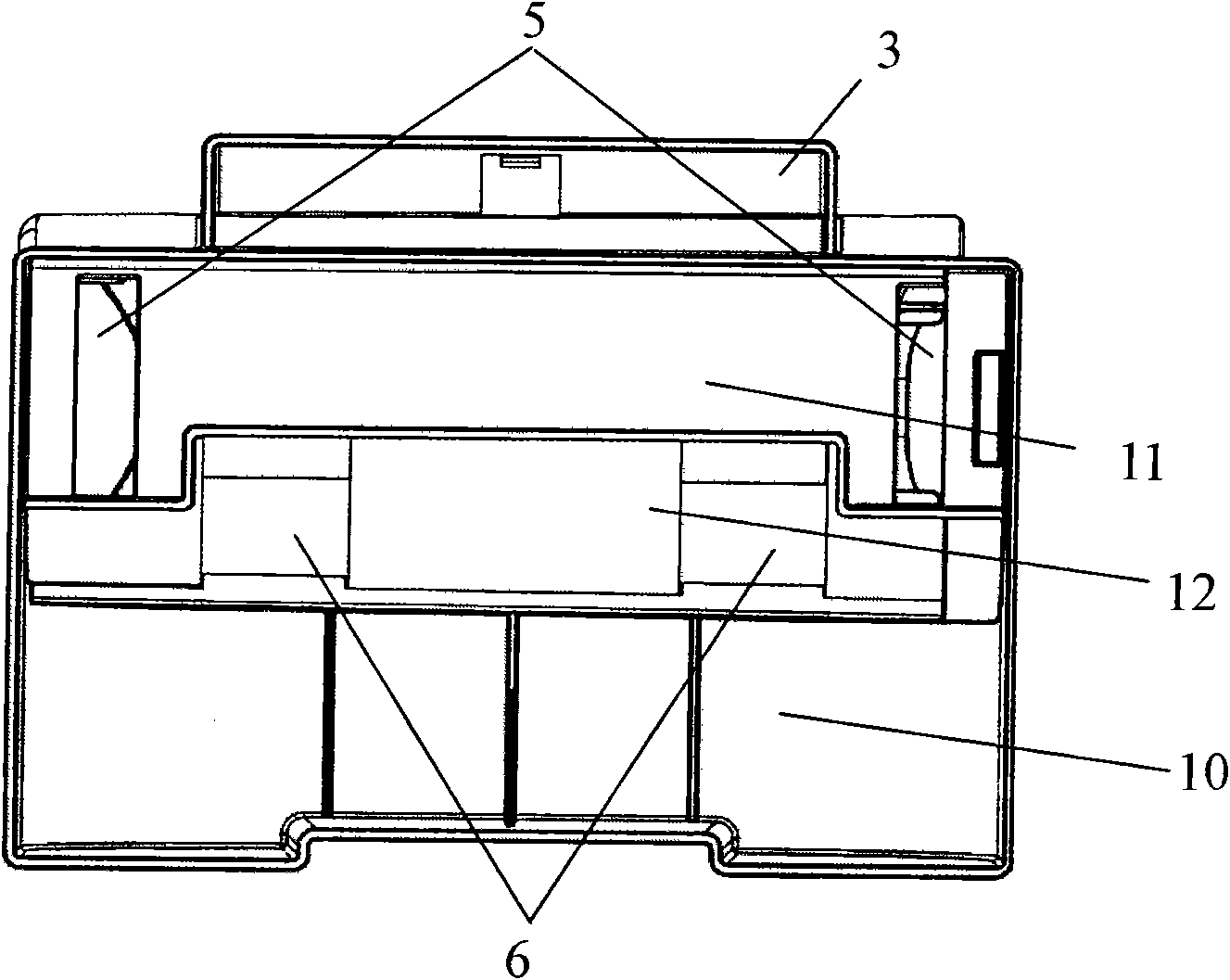

[0025] Such as figure 2 , image 3 As shown, the barrel body 1 has two chambers, a dust separation chamber 8 and a dust collection chamber 10 distributed up and down, the dust separation chamber 8 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com