Nozzle assembly for micro-size hydrogen flame ionization detector

A detector, hydrogen flame technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of long nozzle assembly, complex structure, etc., achieve better performance, half the length, and good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

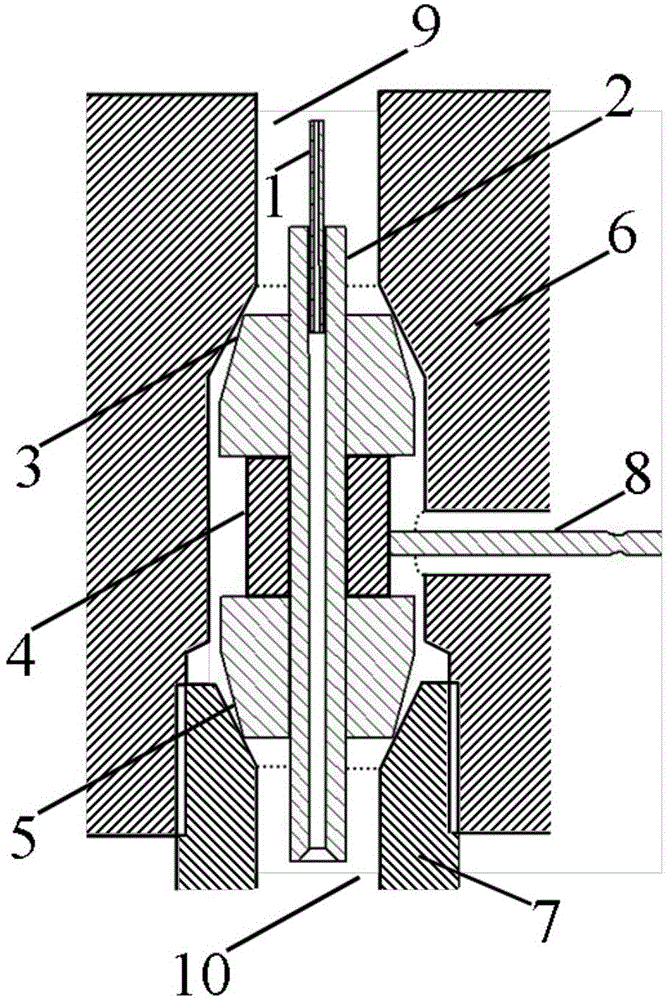

[0032] The μ-FID was developed using the new nozzle assembly, and its cross-sectional schematic diagram is shown in figure 1 As shown, it consists of nozzle 1, guide tube 2, upper ferrule 3, sleeve tube 4, lower ferrule 5 and detector body 6. The material of the nozzle 1, the guide tube 2 and the casing 4 is stainless steel, and the material of the upper ferrule 3 and the lower ferrule 5 is high-temperature-resistant fully aromatic polyimide. The inner diameter of the nozzle 1 is 0.18mm, the outer diameter is 0.38mm, the length of the nozzle 1 extending into and out of the guide tube 2 is 3mm, and a layer of outer diameter 0.6mm and inner diameter 0.4mm is placed between the nozzle 1 and the guide tube 2 The three stainless steel tubes are first mechanically pressed to fix them coaxially, and then silver-welded at the seams to prevent air leakage. The inner diameter of the guide tube 2 is 0.8mm, the outer diameter is 1.6mm, and the length is 17mm; The lower ferrule 5 is clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com