Inverted vacuum diaphragm valve

A diaphragm valve, inverted technology, applied in the direction of diaphragm valve, diaphragm, valve device, etc., can solve the problems of complex manufacturing process, poor airtightness, and increased cost, and achieve the effects of cost reduction, simple sealing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

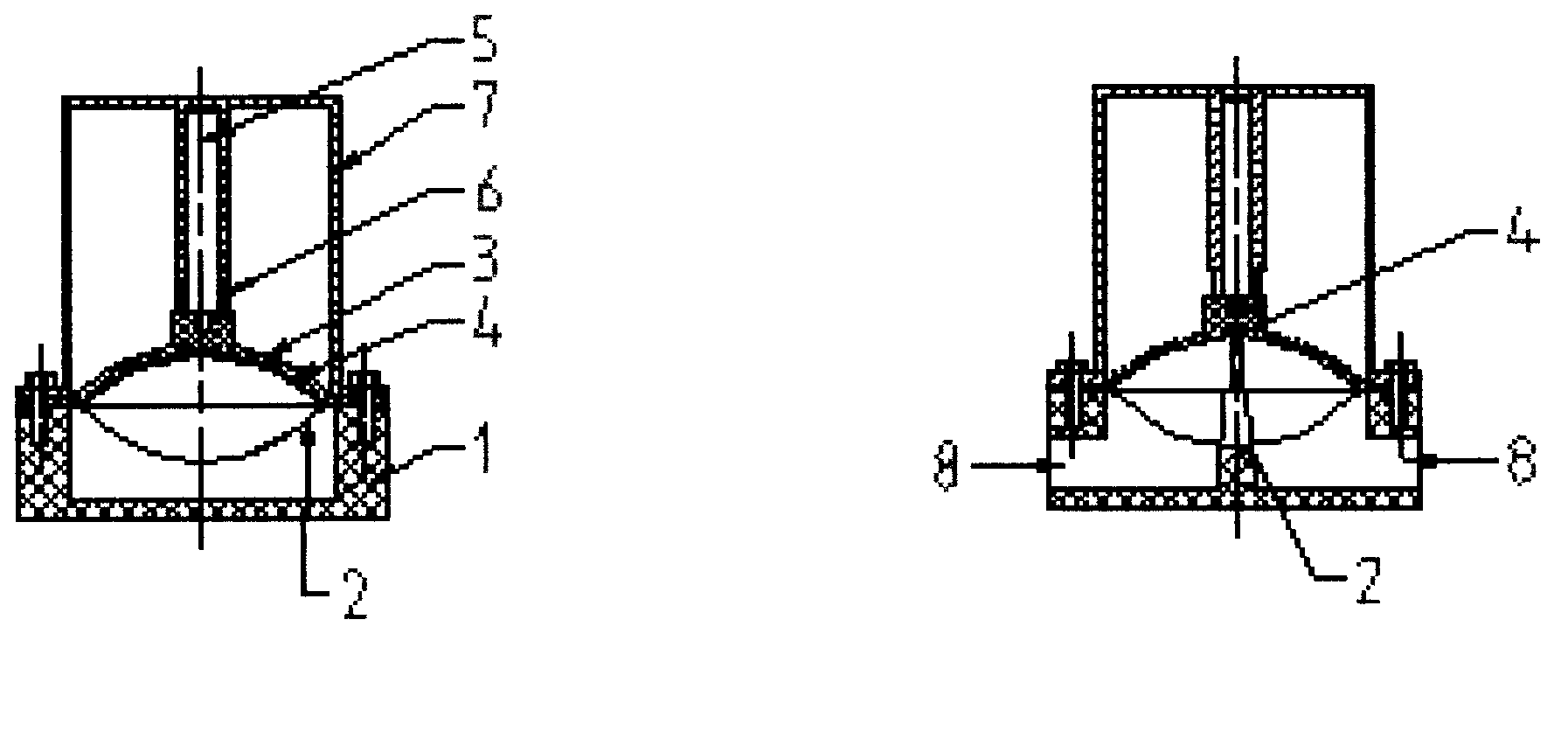

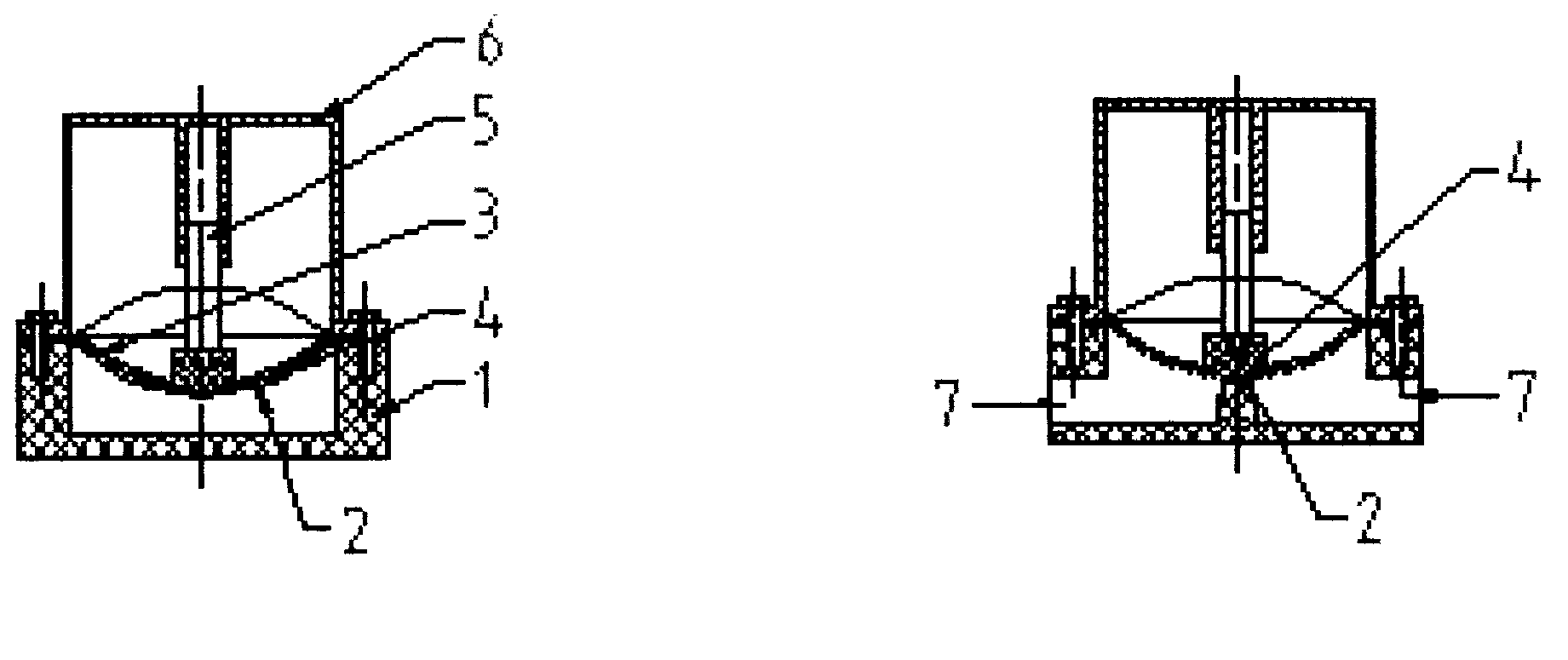

[0015] according to figure 2 As shown, the convex rubber diaphragm 3 is assembled on the valve seat 1 in an inverted way with the concave shape facing upward and the convex shape facing downward, so that the convex surface ribs 4 on the convex rubber diaphragm 3 are aligned with the valve seat 1. When the working program is started, the convex rubber diaphragm 3 and the convex surface rib 4 are sucked up by the vacuum negative pressure to connect the vacuum pipeline system 7. When the working program is stopped, the convex rubber diaphragm 3 The rubber diaphragm 3 and the convex surface ribs 4 naturally fall on the base stem 2 of the valve seat 1 by the force of the downward convex shape, so as to cut off the vacuum pipeline system 7, thereby realizing the opening and closing procedure of the vacuum diaphragm valve .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com