Integrated machine for farmland planting management

A machine and farmland technology, which is applied in the field of farmland planting management integrated machines, can solve the problems of mechanized management of farmland plants and high labor intensity, and achieve the effects of reducing high-intensity labor, saving pesticides, and increasing use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

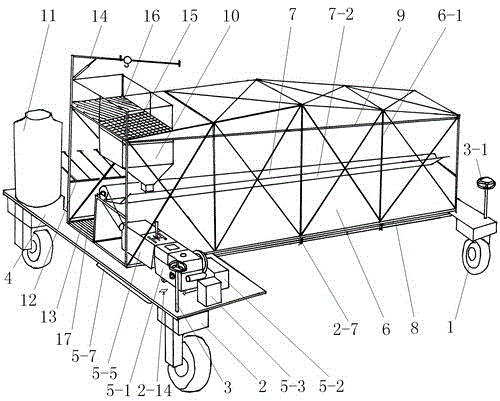

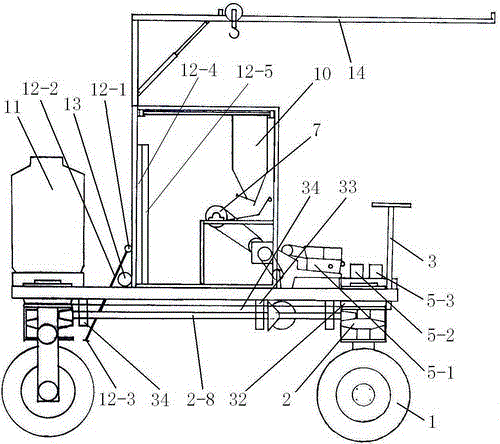

[0038] Embodiment 1: The integrated machine includes: the integrated machine includes: high-pattern paddy field wheel 1, walking system 2, power system 5, steel structure platform 6, sowing fertilizer spreader 7, spraying device 12 and water spraying device; The steel structure platform 6 is connected with the high-pattern paddy field wheel 1 through the walking system 2, and the steel structure platform 6 is connected with a power system 5, a seeding and fertilizer spreader 7, a spraying device 12 and a water spraying device.

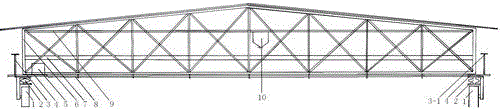

[0039] The steel structure platform 6 includes: a bridge frame 6-1, a lintel 4, a running track 9 for a loading vehicle, a sliding loading vehicle 10, a feeding port 15, a feeding operation platform 16, a pedestrian working aisle 17, guardrails and Hydraulic feeding small crane 14; the bottom surface in the bridge frame 6-1 is connected with a lintel 4, and one end at the upper end of the bridge frame 6-1 has a feed port 15 and a feed operation plat...

Embodiment 2

[0053] Embodiment 2: The hydraulic motor walking system includes: a-wheel hydraulic motor 18, a-wheel oil supply pipeline 19, ab-wheel shared oil return pipeline 20, b-wheel oil supply pipeline 21, hydraulic travel master pump 22, sowing wheel hydraulic pressure Motor oil supply pipeline 23, b hydraulic motor 24, sowing wheel hydraulic motor oil return pipeline 25, sowing wheel hydraulic motor 26, cd wheel return oil pipeline 27, d wheel oil supply pipeline 28, c wheel oil supply pipeline 29, d wheel hydraulic motor 30 and c wheel hydraulic motor 31; hydraulic travel master cylinder 22 is respectively connected with a wheel hydraulic motor 18, b wheel oil supply pipeline 21, c wheel oil supply pipeline 29 and d wheel oil supply pipeline 28 through a wheel oil supply pipeline 19, b wheel oil supply pipeline 28 The hydraulic motor 24, the c wheel hydraulic motor 31 and the d wheel hydraulic motor 30 are connected; the oil return pipeline 20 shared by the ab wheel and the oil retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com