Bottle inspection and elimination device and working method thereof

A technology for rejecting devices and bottles, which is applied in sorting and other directions, can solve the problems of bottle falling, manual height adjustment, and high requirements for the position adjustment of the hitting device, etc., to achieve the effect of rapid removal and prevention of bottle dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

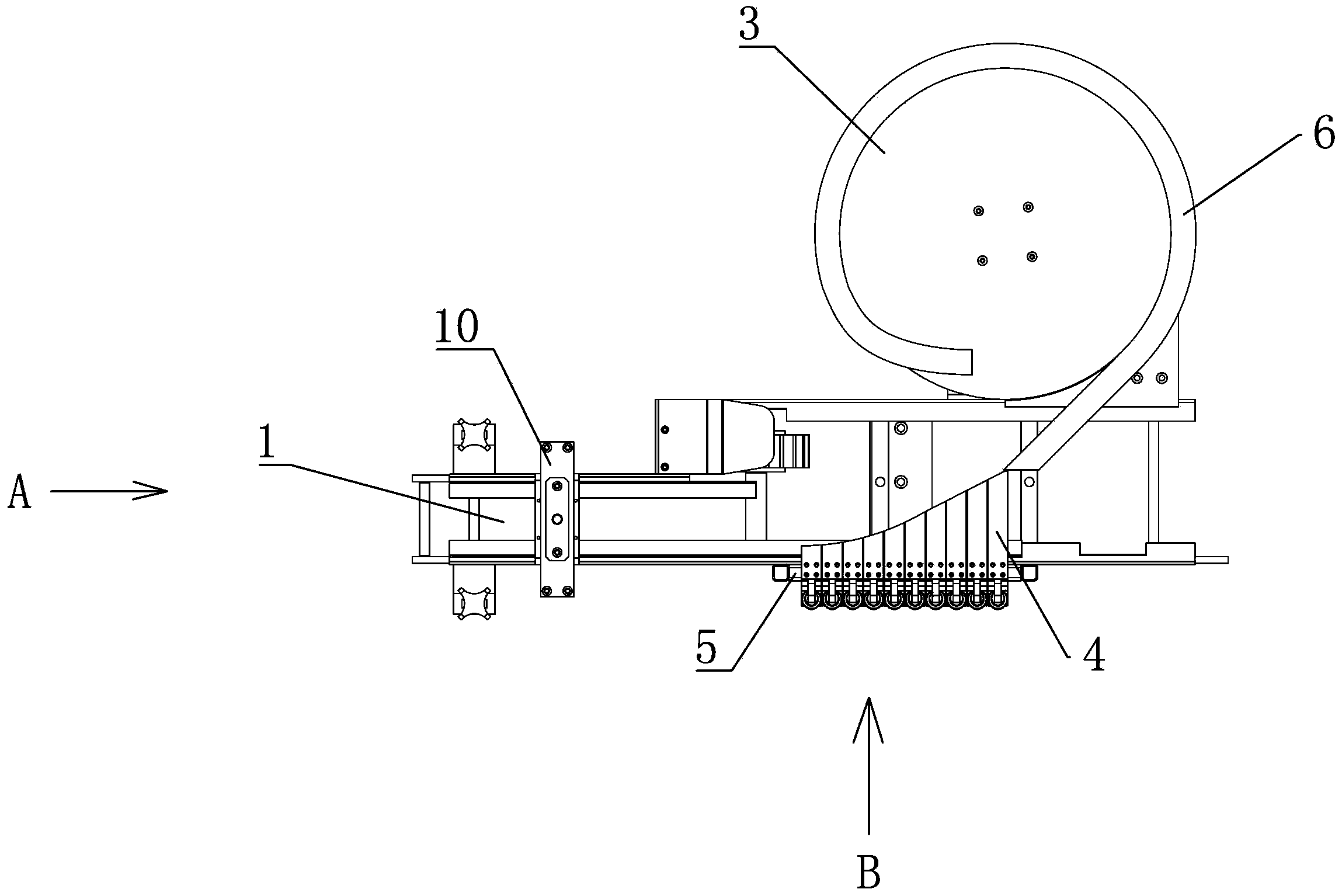

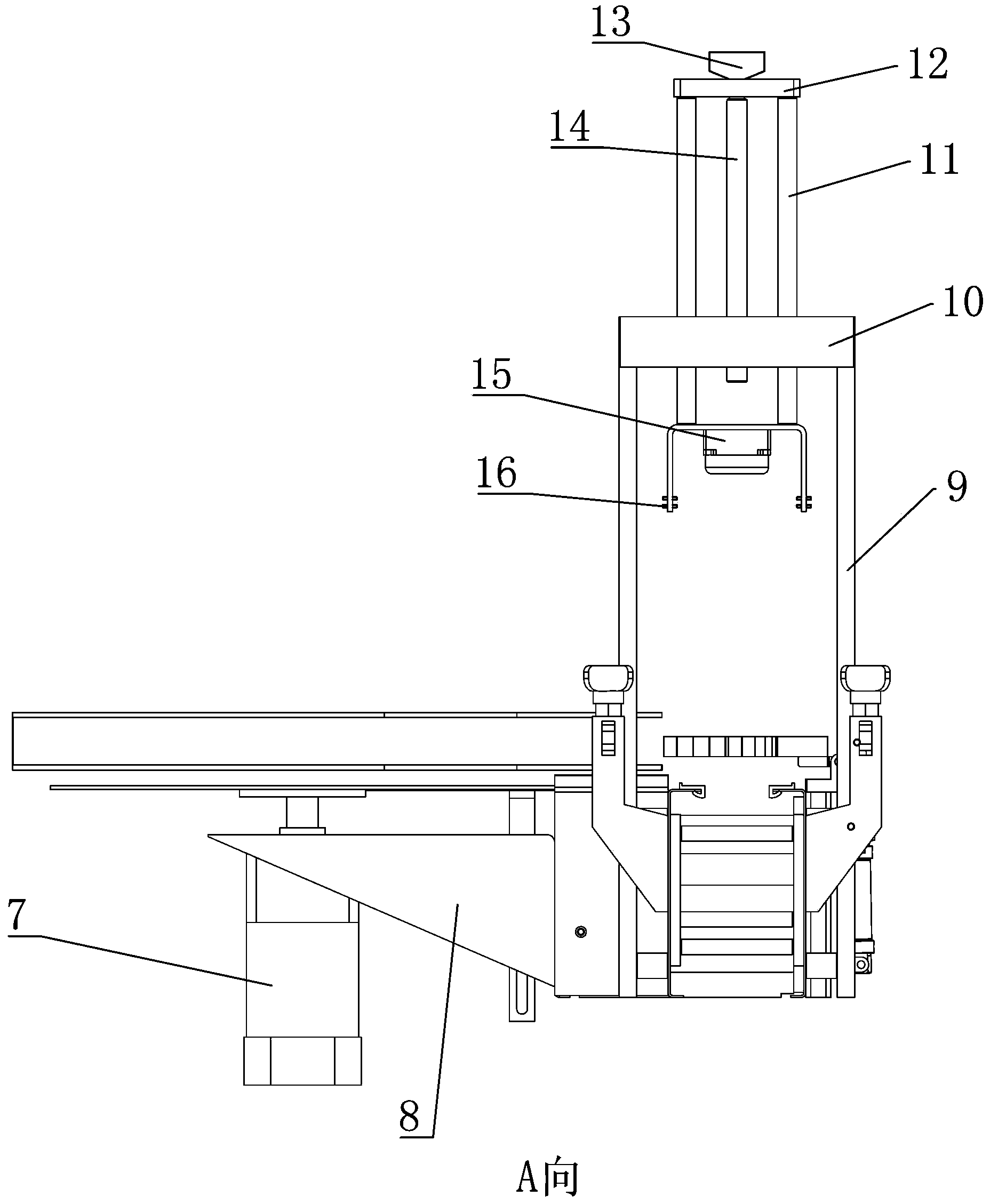

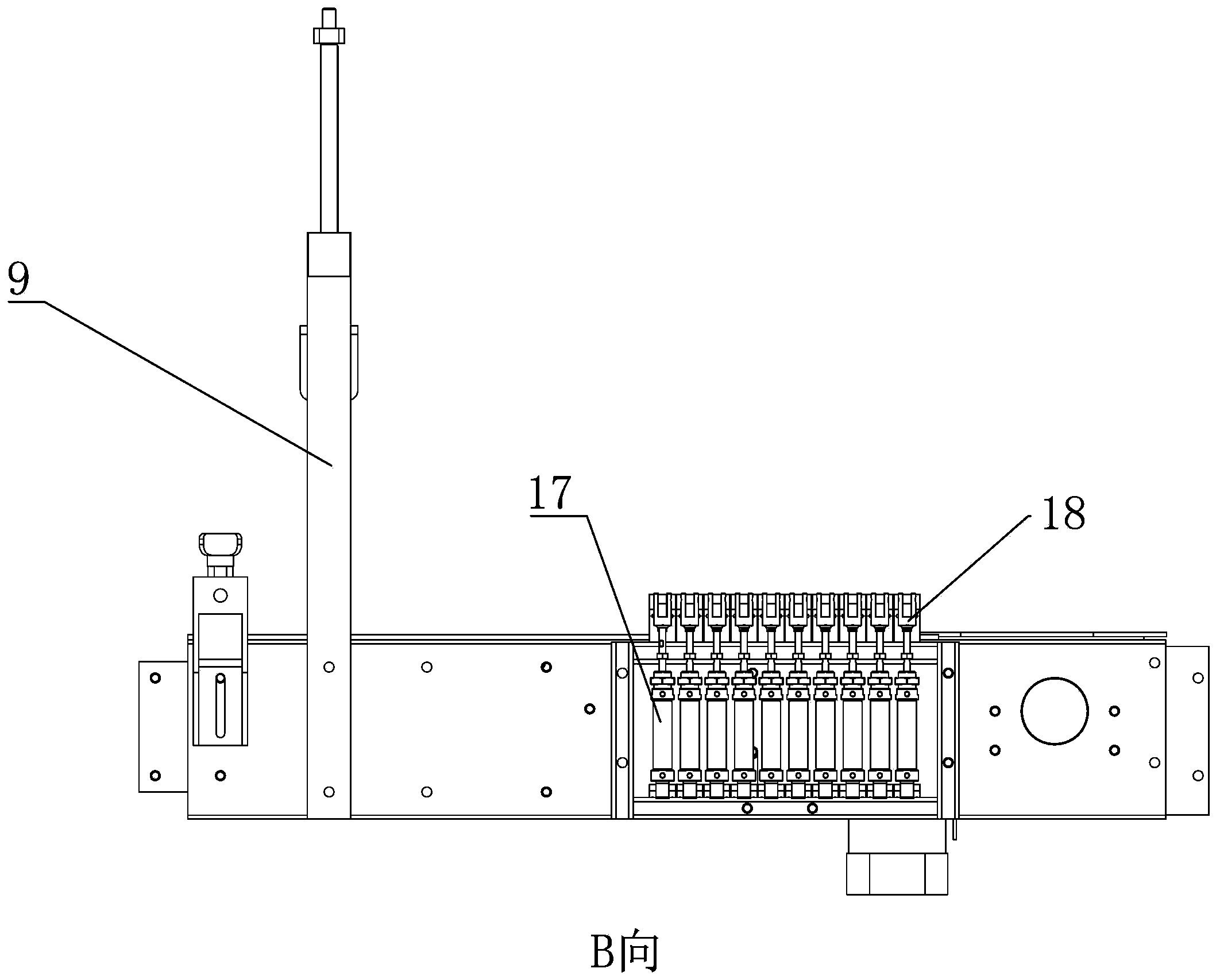

[0024] Such as Figures 1 to 5 As shown, the frame 19 is provided with a conveyor belt 1 for conveying bottles, and along the direction of the conveyor belt 1, a plurality of rejecting fingers 4 are arranged, and the rejecting fingers 4 are arranged adjacent to each other from short to long along the conveying direction, and the fingers 4 are rejected. The front end is distributed in a straight line with uniform acceleration, and the middle and rear parts of each rejecting finger 4 are rotated and fitted on an axis 5, and the rear ends of each rejecting finger 4 are respectively connected by a fork-shaped connecting rod 18 and a cylinder 17 that drives the rejecting finger 4.

[0025] The conveyer belt 1 is positioned at the front and back of the left end of the rejecting finger 4 and is arranged in parallel with a pair of support rods 9, the top of the support rods 9 is fixed with an adjustment block 10, the adjustment block 10 is provided with two through holes and a threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com